Passive element packaging structure and making method thereof

A technology of passive components and packaging methods, which is applied in the direction of assembling printed circuits with electrical components, electrical components, and printed circuits connected with non-printed electrical components, which can solve the problems of large occupied space and non-compliance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

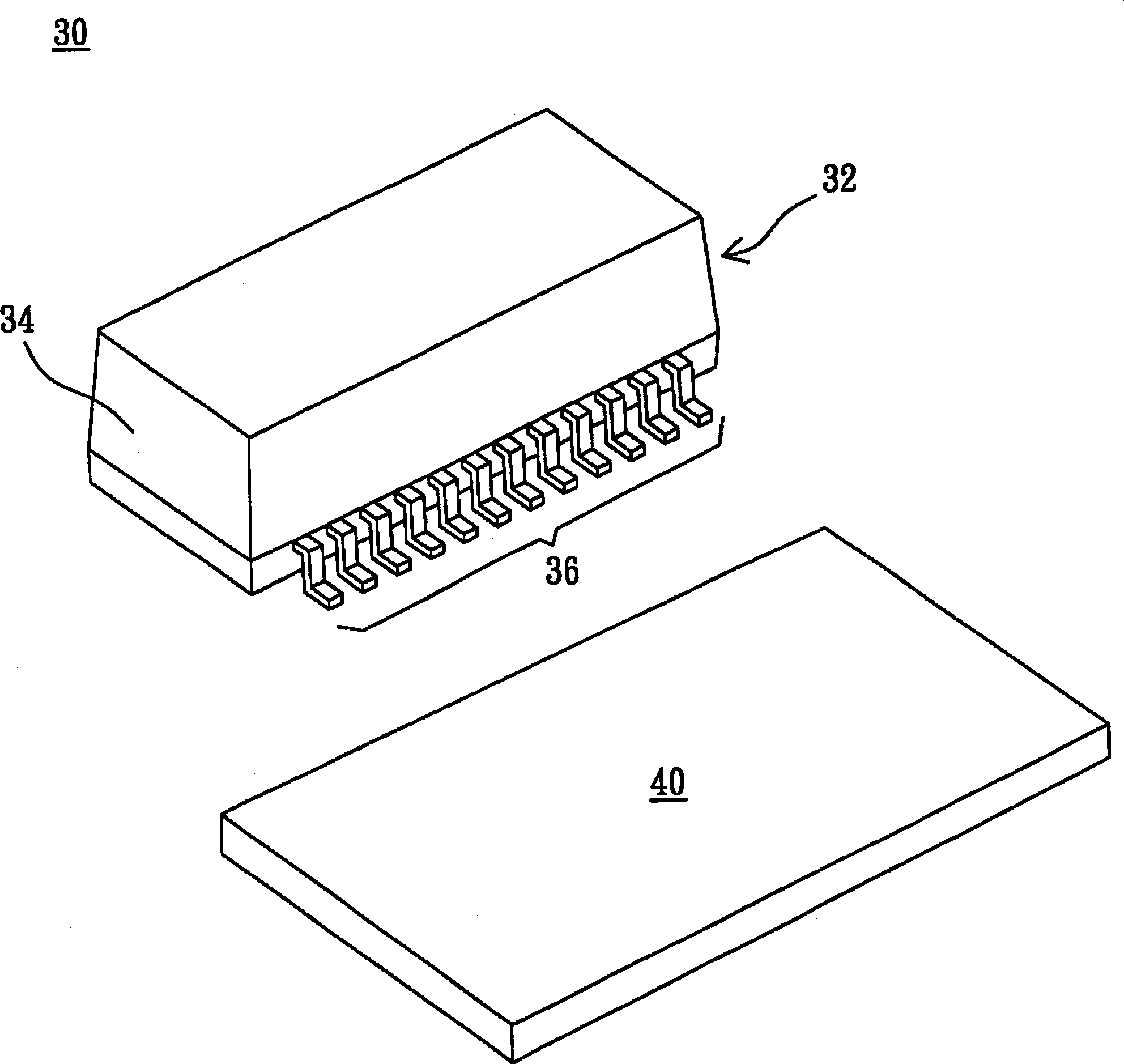

[0022] In order to describe the structure and principle of the passive component packaging structure and manufacturing method of the present invention in detail, the following passive components will use a transformer as an example to illustrate the spirit of the present invention.

[0023] Please refer to Figure 3A and Figure 3B . Figure 3A and Figure 3B is a schematic diagram showing the transformer module of the present invention. Such as Figure 3A and Figure 3B As shown, the transformer module of the present invention includes a base plate 50 and a plurality of annular iron cores 60 , 66 , 70 and 76 .

[0024] The cores 60 , 66 , 70 and 76 are wound with more than two coil windings 62 to serve as primary and secondary coils of the transformer. The substrate 50 is a printed circuit board (Printed CircuitBoard; PCB), which has a corresponding first surface 52 and a second surface 82. First, a plurality of pieces of copper or copper alloy metal are disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com