Swivel joint for construction machine

A technology of construction machinery and rotary joints, which is applied in construction, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve problems such as difficulty in completely preventing water from entering, corroded rotary joints are stuck, and poor workability, etc., to achieve replacement operations Easy, compact piping, improved dust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

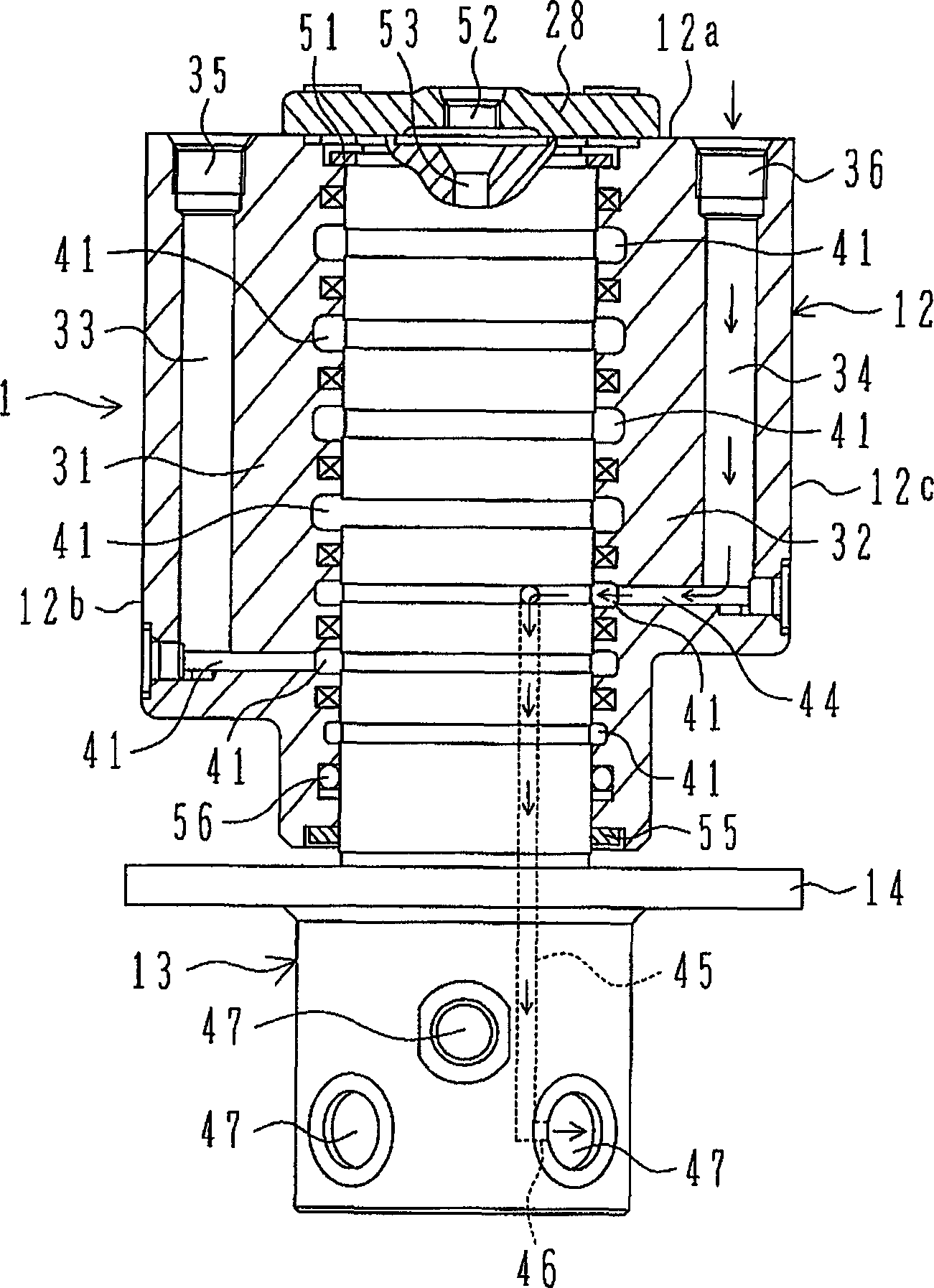

[0027] Embodiments of the present invention will be described below with reference to the drawings.

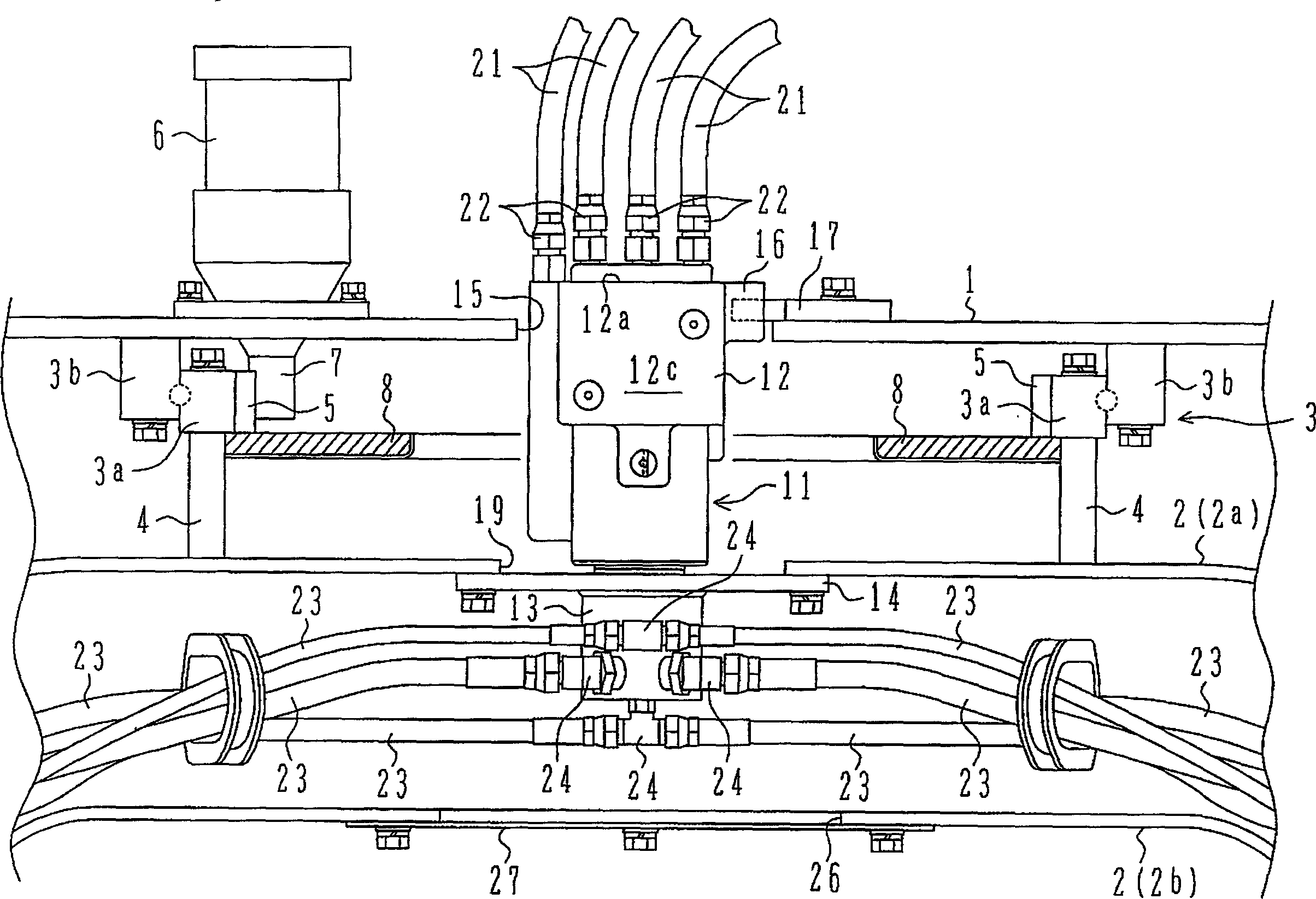

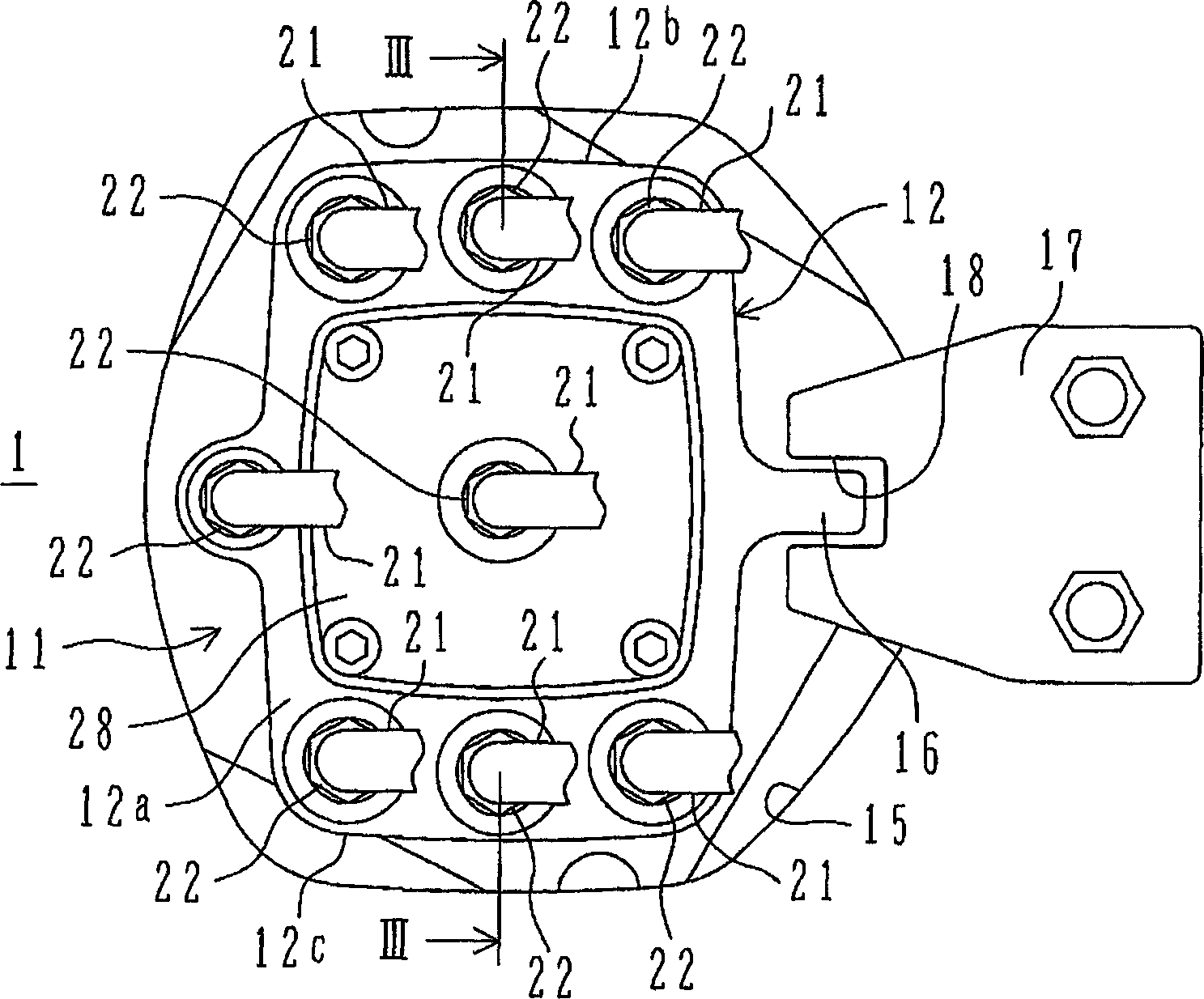

[0028] figure 1 It is a figure which shows the state which mounted the swivel joint of this invention between the revolving body and the traveling body of a hydraulic excavator.

[0029] exist figure 1 Among them, the symbol 1 is the main frame forming the bottom of the revolving body, and the symbols 2a and 2b are the upper track frame and the lower track frame constituting the track frame 2 of the walking body. The slewing wheel 3 composed of an inner ring 3a and an outer ring that can rotate relative to each other is located between the main frame 1 and the upper crawler frame 2a. On the wheel support portion 4, the outer ring 3a is fixed to the lower surface of the main frame 1 by bolts. The inner side of the inner ring 3 a is cut into a gear 5 with internal teeth, which meshes with a pinion 7 provided on the output shaft of the swing motor 6 . The rotary motor 6 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com