Automobile structure lightweighting design method based on structure intensity variation characteristic

A lightweight design and automotive structure technology, applied in computing, motor vehicles, special data processing applications, etc., can solve the problem that the potential of materials cannot be fully utilized, and achieve high reliability and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

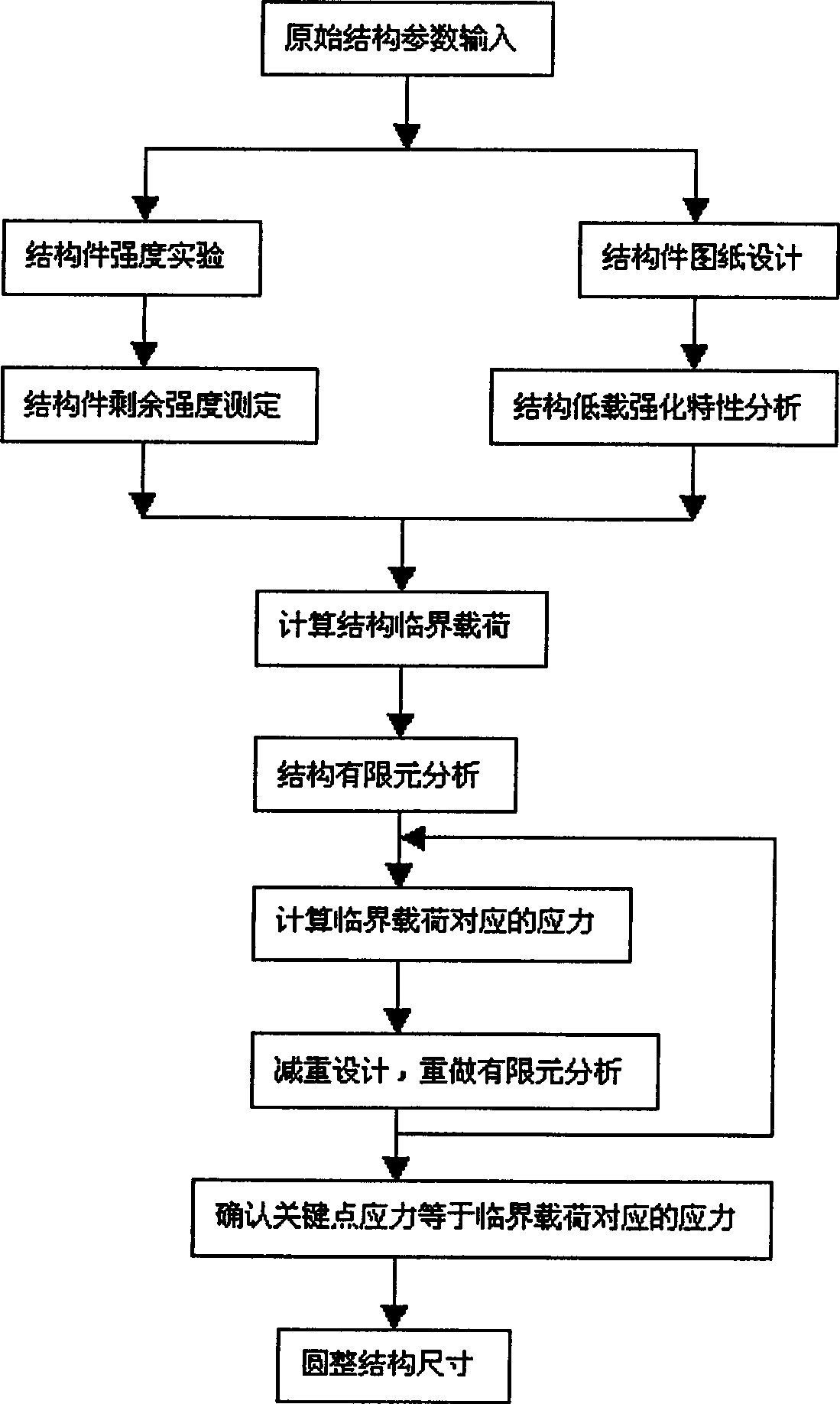

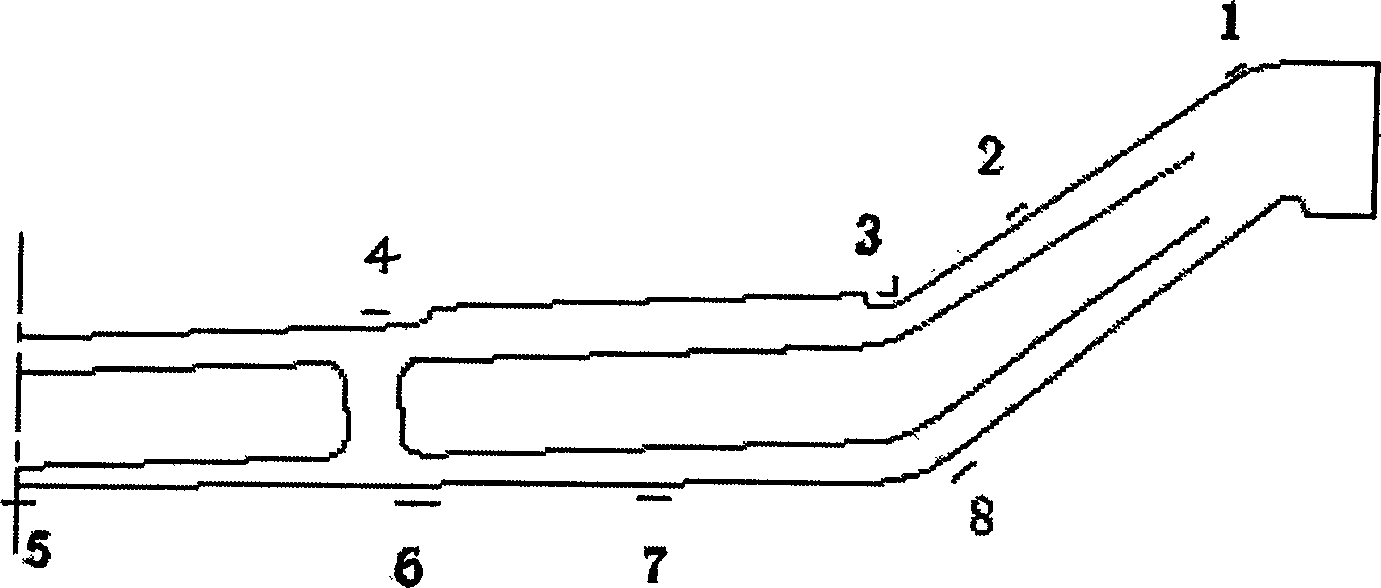

[0022] A lightweight design method for automobile structures based on structural strength variation characteristics: Taking the design of the front axle of a 5-ton truck as an example, the design process is shown in figure 1 , the method steps are:

[0023] 1. Determine the strength change of the structure under a given load condition through the strength test:

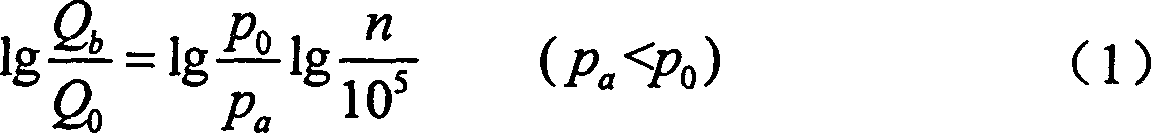

[0024] According to the static strength of the structural parts measured after a given load cycle, the critical load p of the structure can be easily calculated by using formula (1) 0 . The critical load is physically similar to the fatigue limit of a material, corresponding to making the structure fatigue life 10 6 times load. Since it is necessary to consider many uncertain factors and parameters to deduce the fatigue limit of the structure from the material parameters, the critical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com