Static mud protecting wall type drilling and boring process employing rotary drilling rig

A technology of rotary drilling drilling machine and mud retaining wall, which is applied in the direction of earth mover/excavator, foundation structure engineering, sheet pile wall, etc., and can solve problems such as economic loss, inconvenient construction, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

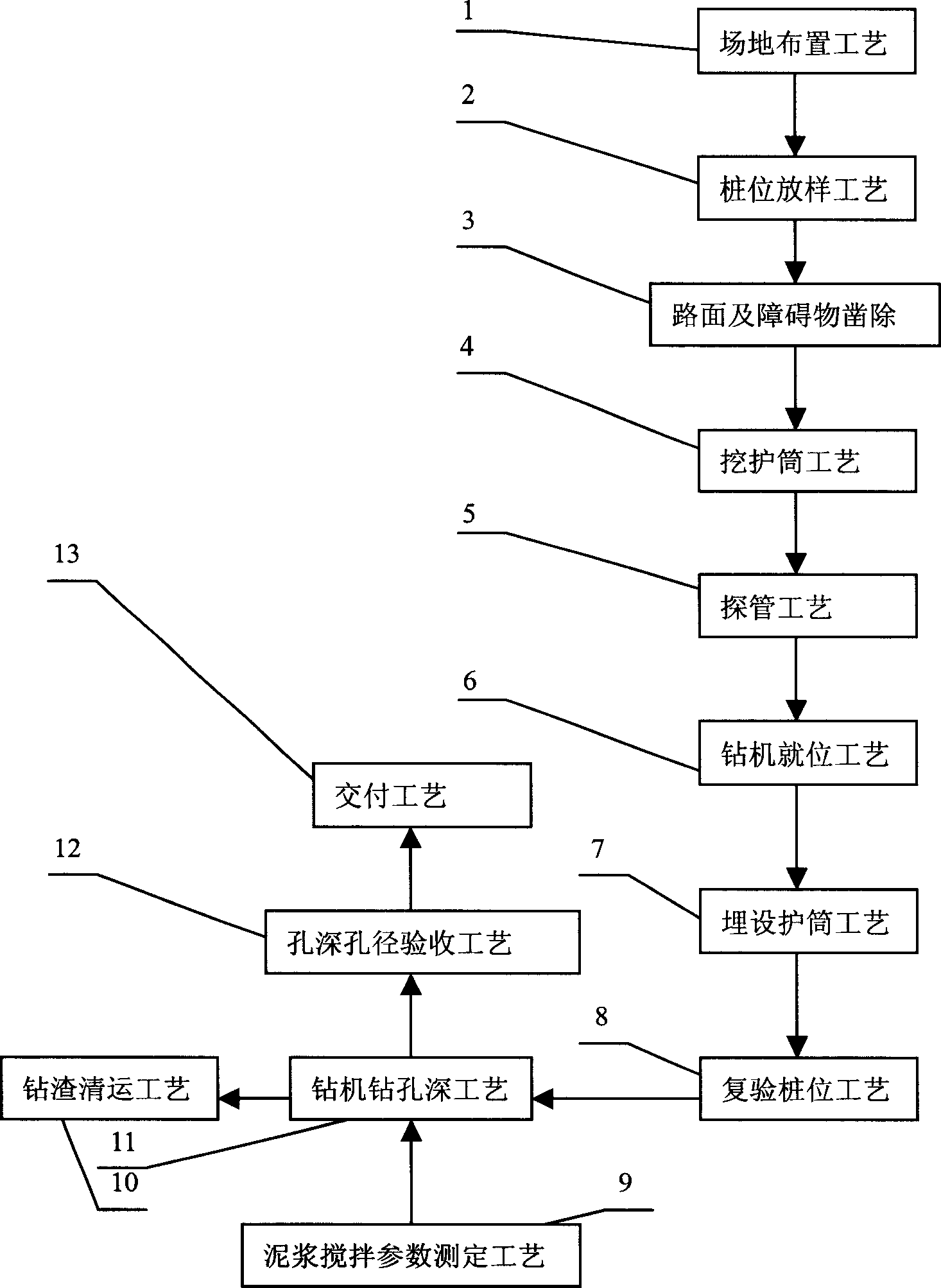

[0012] The construction process of the static mud retaining wall drilling method of the rotary drilling machine firstly carries out the site layout process (1), and after the site layout process (1) is completed, the pile position setting out process (2) is carried out, and the pile position setting out process (2) ) after the pavement and obstacle removal process (3), after the pavement and obstacle removal process (3) is completed, the casing excavation process (4) is carried out, and after the casing excavation process (4) is completed, the probe pipe process (5) is carried out ), after the probe process (5) is completed, the drilling process (6) is carried out, after the drilling process (6) is completed, the casing process (7) is carried out, and after the process (7) is completed, the casing process is repeated After the pile position inspection process (8), the pile position re-inspection process (8) is completed, the mud stirring parameter measurement process (9) is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com