Nanometer aquogel with both pH and temperature sensitivity and its prepn process

A technology of nano-hydrogel and dissolution temperature, which is applied in the field of pH- and temperature-sensitive N-isopropylacrylamide nano-hydrogel and its preparation, and can solve the problem of not being able to reach the nanometer level, limiting applications, and single sensitive type and other problems, to achieve the effect of rapid response capability and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

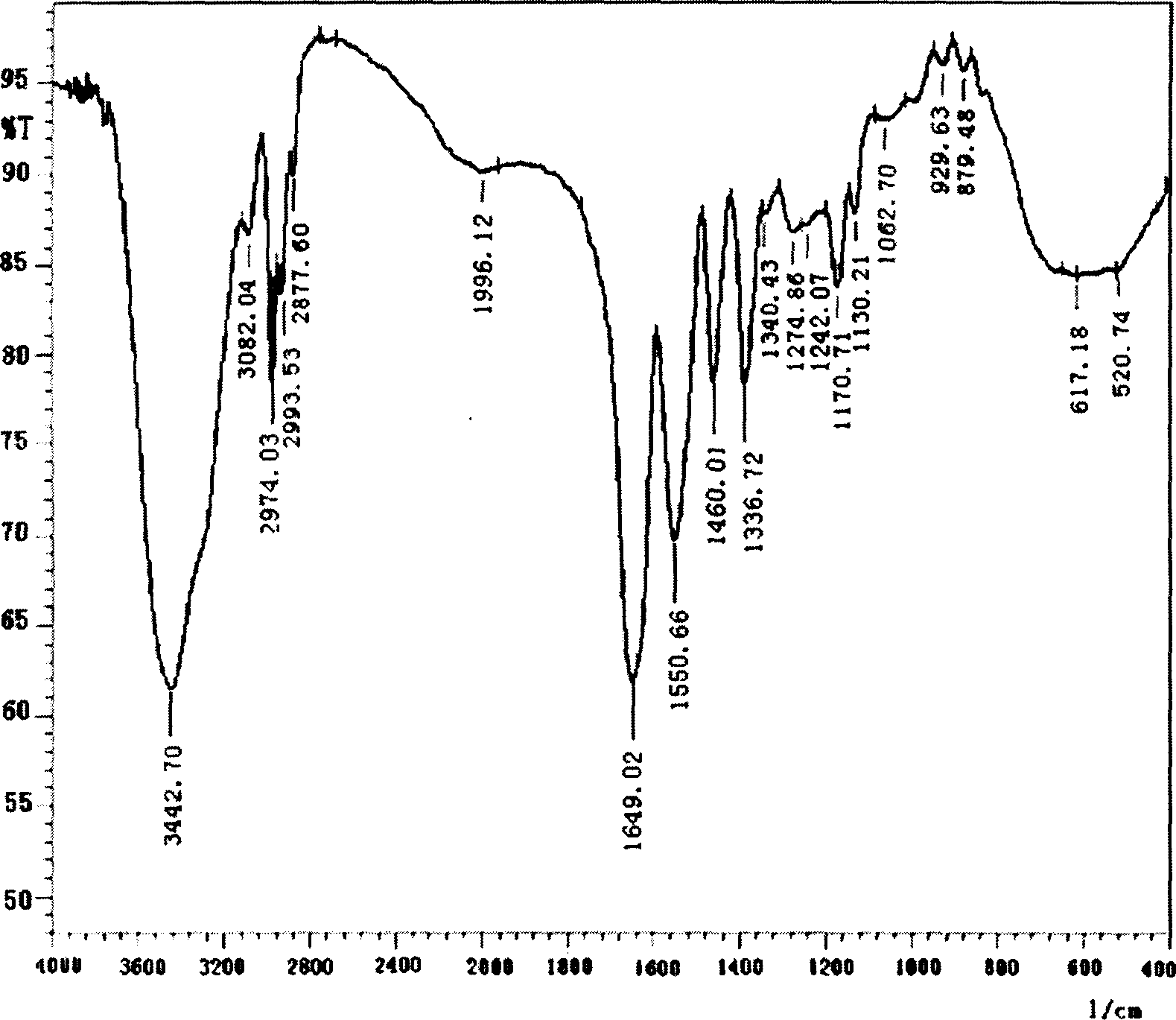

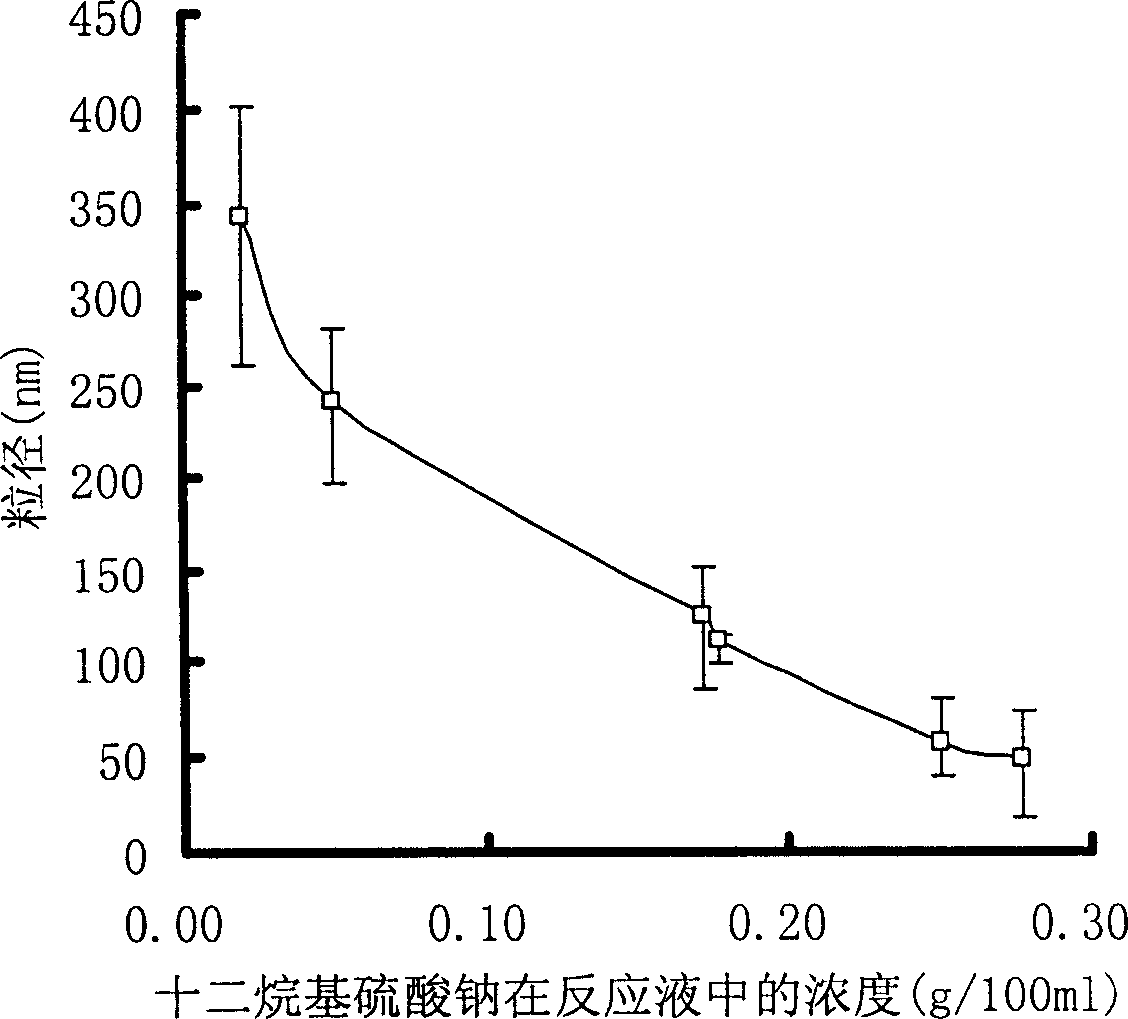

[0038] Dissolve 3.7770g of N-isopropylacrylamide, 0.18mL of acrylic acid, 0.0690g of N,N'-methylenebisacrylamide, 0.3366g of dodecylsulfuric acid in 230mL of aqueous solution and add to the have N 2 Catheter in a 500mL three-neck flask. Stir at a rate of 400 rpm, and feed N 2 After fully deoxidizing, heat with a water bath. Add 0.0624 g of an aqueous solution of potassium persulfate, adjust the volume of the reaction solution to 370 mL, and react at 70° C. for 4 h. The product obtained is fully dialyzed with distilled water (dialysis bag, molecular weight cut-off is 10,000), and then freeze-dried to obtain a PNIPAM-co-AA (acrylic acid) nano-hydrogel with a particle size of 110nm ± 15nm. The LCST is 35°C. Infrared spectrogram see figure 2 .

Embodiment 2

[0040] Dissolve 3.7770g of N-isopropylacrylamide, 0.81mL of acrylic acid, 0.0690g of N,N'-dodecylmethylenebisacrylic acid amine, and 0.6366 octaalkyl sodium sulfate in 230mL of aqueous solution and add an electric stirring device and a thermometer. and equipped with N 2 Catheter in a 500mL three-neck flask. Stir at a rate of 400 rpm, and feed N 2 After fully deoxidizing, heat with a water bath. Add 0.0624g of an aqueous solution of ammonium persulfate, adjust the volume of the reaction solution to 370mL, and react at 70°C for 4h. The obtained product was fully dialyzed with distilled water (dialysis bag, molecular weight cut-off is 10,000), and then freeze-dried to obtain a PNIPAM-co-AA (acrylic acid) nanohydrogel with a particle size of 48nm ± 10nm, and an LCST of 43.8°C.

Embodiment 3

[0042] Dissolve 3.7770g of N-isopropylacrylamide, 0.30mL of acrylamine, 0.0690g of N,N'-diallyl tartaric acid diamide, 0.6366g of sodium lauryl sulfate in 230mL of aqueous solution and add an electric stirring device and a thermometer. and equipped with N 2 Catheter in a 500mL three-neck flask. Stir at a rate of 400 rpm, and feed N 2 After fully deoxidizing, heat with a water bath. Add 0.0624g of an aqueous solution of N,N,N',N'-tetramethylethylenediamine, dilute the reaction solution to 370mL, and react at 70°C for 4h. The obtained product was fully dialyzed with distilled water (dialysis bag, molecular weight cut-off is 10,000), and then freeze-dried to obtain PNIPAM-co-NH with a particle size of 95nm±10nm 2 (Acylamine) nanohydrogel, LCST is 39.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com