High temeprature and pressurized water vapor preparing porous ceramic device

A technology of porous ceramics, high temperature and pressure, applied in the direction of steam superheating, steam generation, lighting and heating equipment, etc., to achieve the effect of flexible operation, convenient inspection and maintenance, and high heat recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

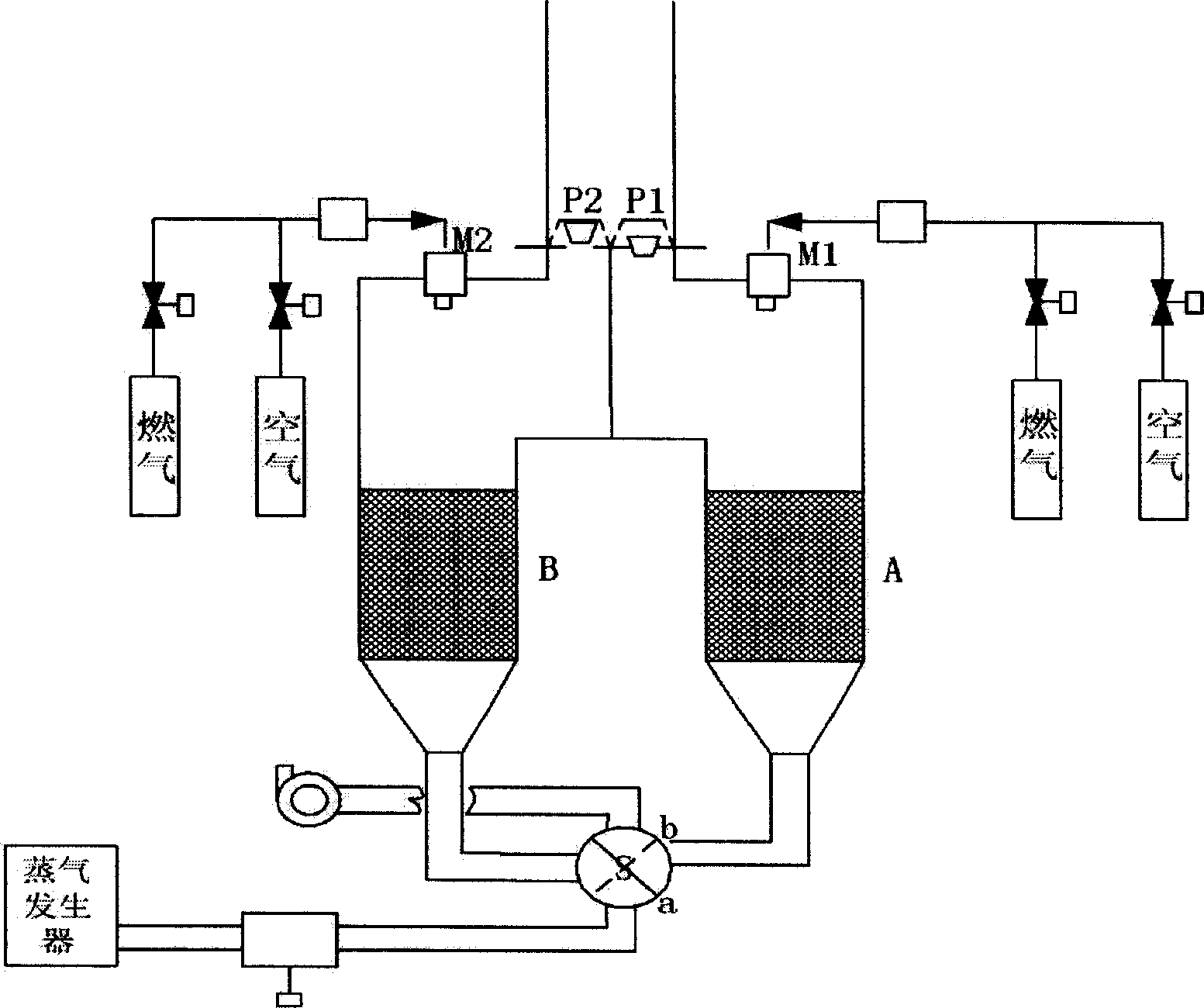

[0009] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0010] The working process of porous ceramic chamber A:

[0011] When the four-way reversing valve S is in state a, gas / fuel is sprayed into the combustion chamber from the nozzle M1 and burned, heating the porous ceramic chamber A. Since the pressure in the combustion chamber is lower than the pressure of the high-temperature pressurized water vapor, the valve P1 is closed and the valve P2 is opened. The high-temperature flue gas enters the porous ceramic chamber A, fully contacts with the porous ceramic and conducts efficient heat exchange. During this process, the high-temperature flue gas transfers heat to the porous ceramics to the limit, and the temperature of the flue gas drops rapidly to 150-200°C and then exits the system. At this time, the reversing valve S operates, and it is in state b. At this time, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com