Modelling method for predicating impurity component concentration for dimethyl benzene oxidation process

An oxidation process, paraxylene technology, applied in the direction of instrumentation, adaptive control, control/regulation system, etc., can solve the problems of outlier sensitivity, overfitting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

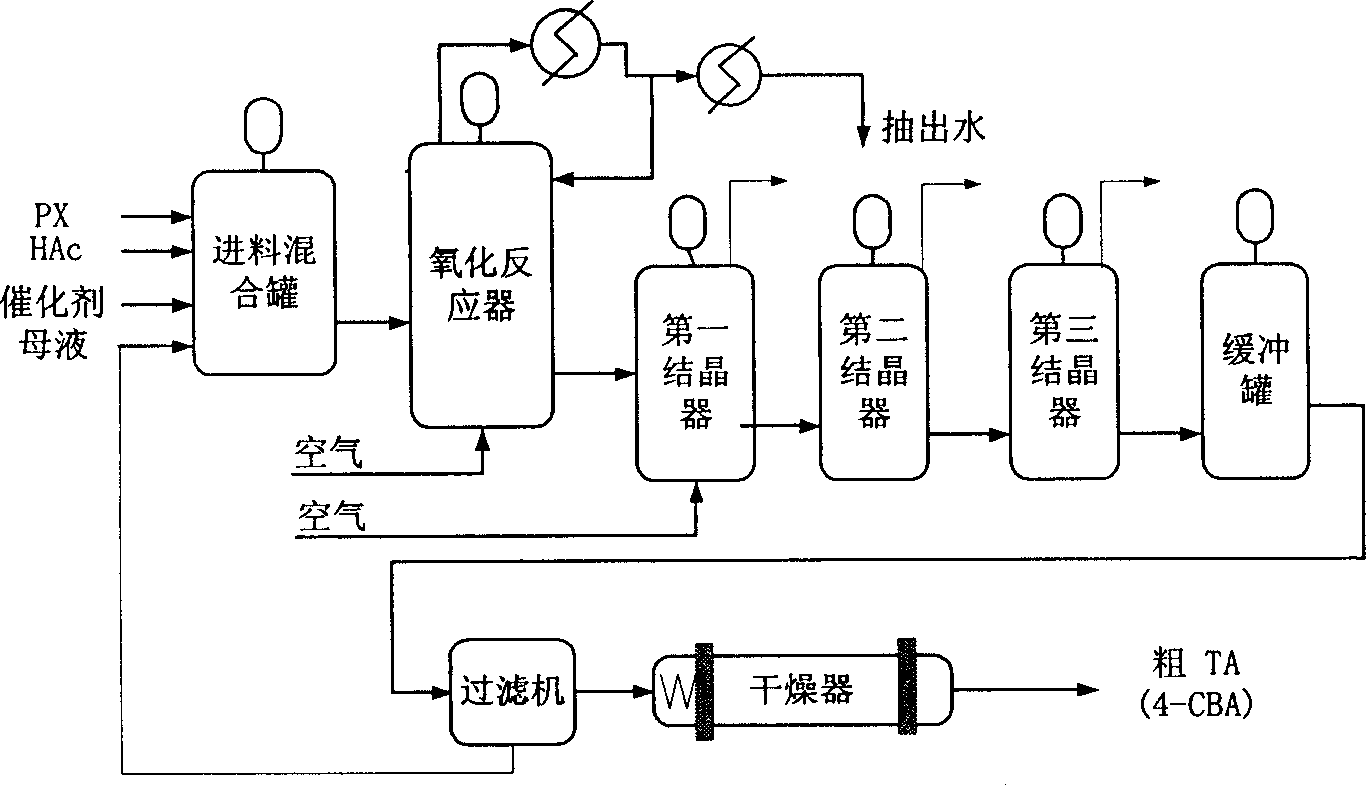

[0081] Taking the prediction of 4-CBA content in the PX oxidation process of a refining and chemical enterprise as an example, the modeling methods based on fuzzy support vector regression method and SVR method, fuzzy neural network and mechanism model were compared.

[0082] During the PX oxidation process, the DCS system collects data every half a minute, and there are hundreds of process variables collected. It is impractical to use all these variables as input variables of the model. On the one hand, it will complicate the model. , on the other hand, it will reduce the predictive ability of the model, so it is necessary to select the input variables of the model before establishing the soft sensor model. A relatively simple and practical variable selection method is the prior method, which selects the input variables of the model according to the field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com