Coated yarns

A yarn and coating technology, applied in the field of coating self-locking yarn, can solve problems such as damage to the sewing needle sewing device, damage to the fabric, inaccurate stitching connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the existing garment industry, standard seaming yarns made of cotton or polyester fibers are used for button seaming. Different trials were carried out by coating soft cotton yarns, mercerized cotton yarns and high tenacity polyester staple fibers with different polymeric binders and copyester esters. However, the adhesion of the coated adhesive and subsequent activation was not satisfactory for the final use, the yarn applied was 118 dtex (detect) x 3 mercerized cotton, 147 dtex (dtex ) × 2 soft cotton, 98 decitex × 3 polyester staple fiber, 83 decitex × 3 polyester staple fiber, 205 decitex × 2 polyester cotton core-spun yarn and 205 decitex × 3 polyester cotton core-spun yarn.

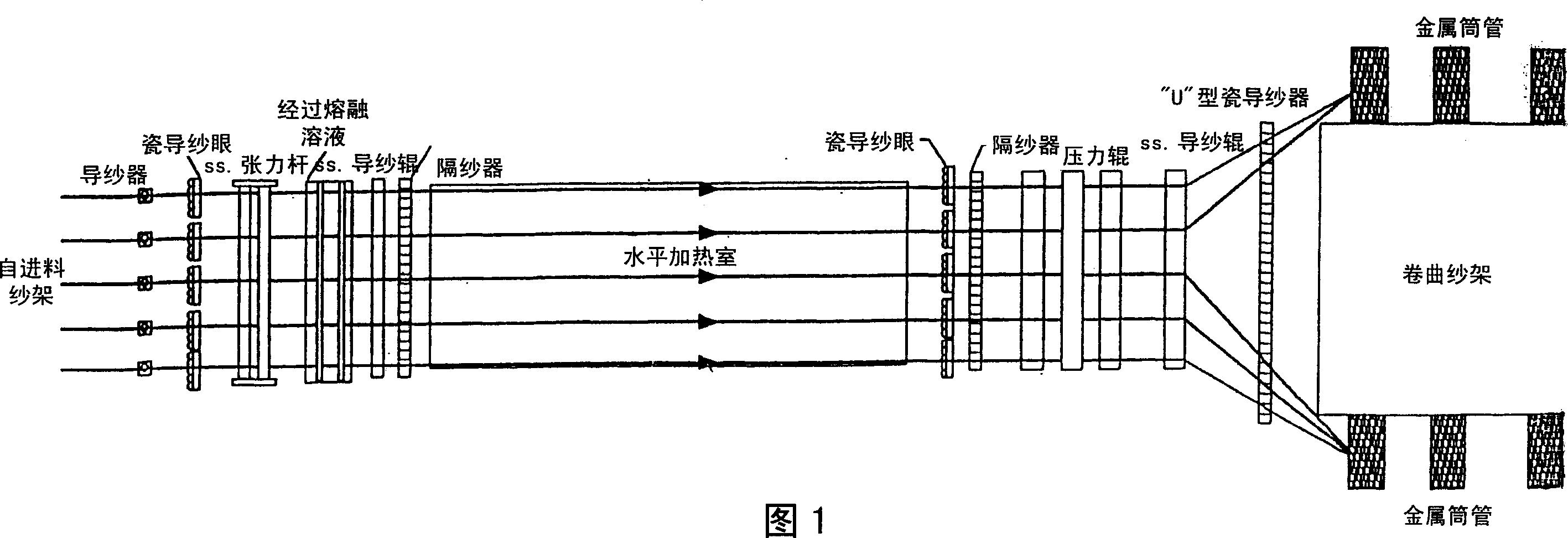

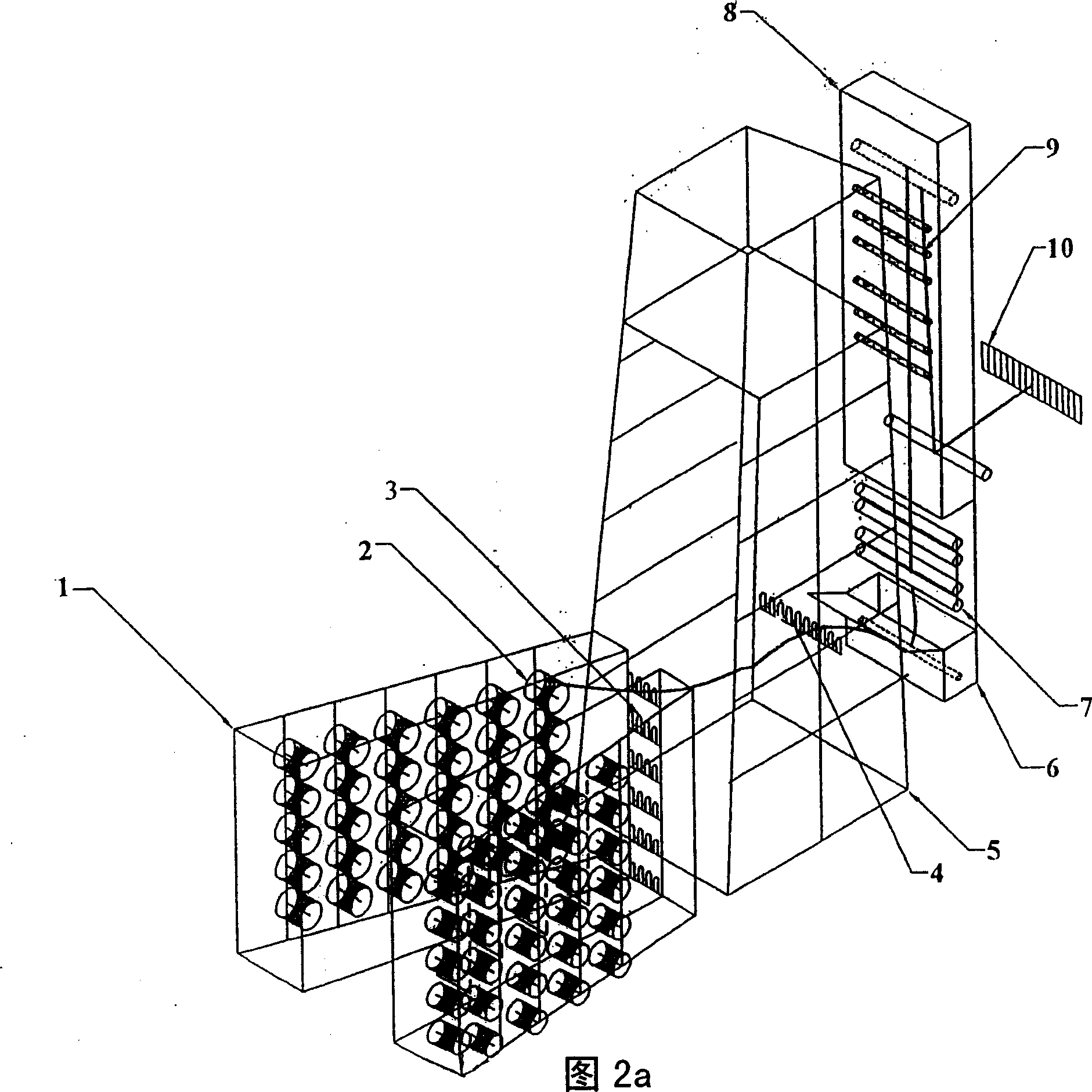

[0053] Dyed yarns of the above structure are used in the following techniques:

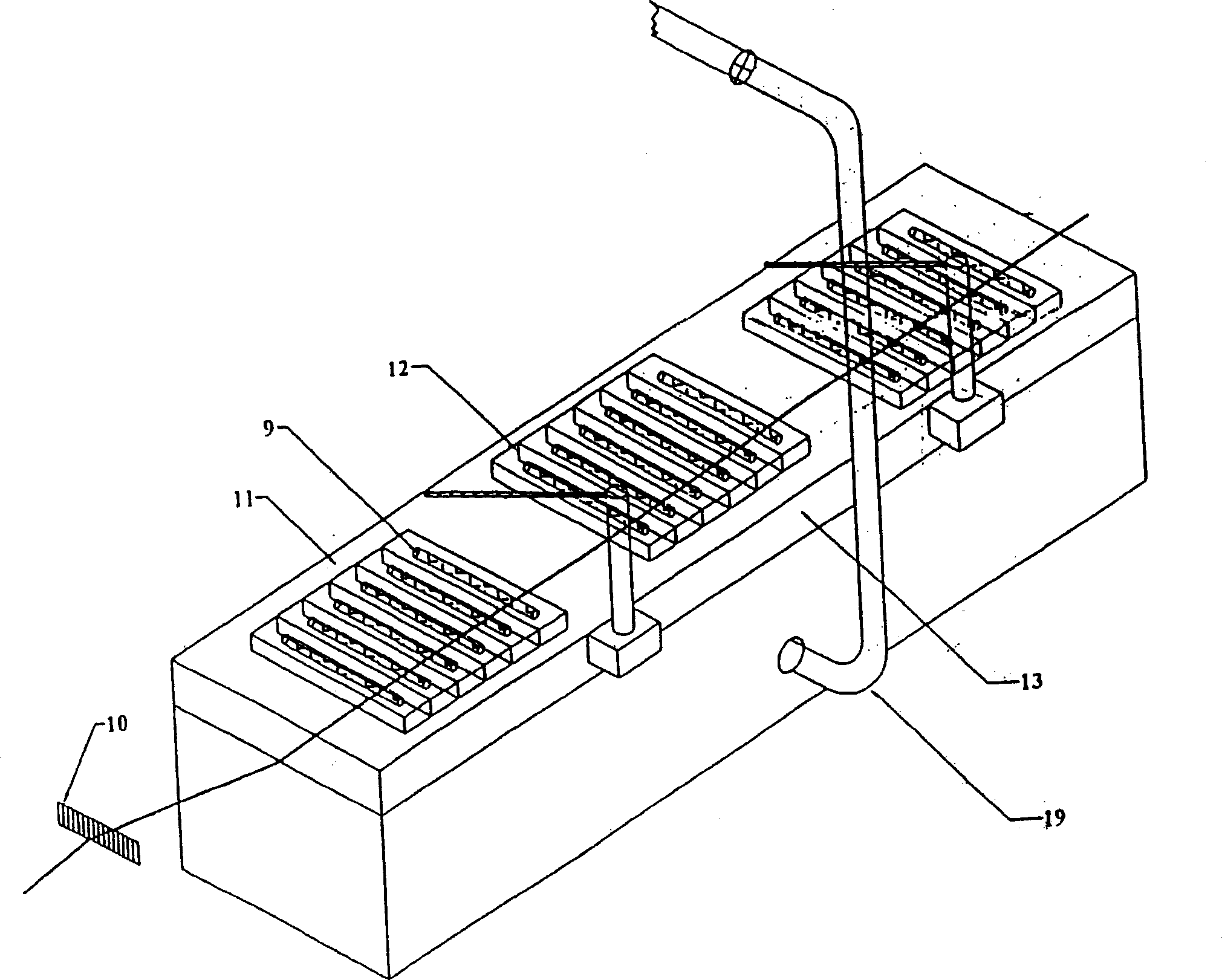

[0054] Method A: Application of Low Density Polyethylene (LDPE) and High Density Polyethylene (HDPE) dissolved in a suitable solvent in a high temperature and high pressure package dyeing machine through an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com