Actuator

A brake device and brake technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, textiles and papermaking, etc., can solve the problem of 38 flatness of the braking surface (smoothness is easy to produce deviations, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

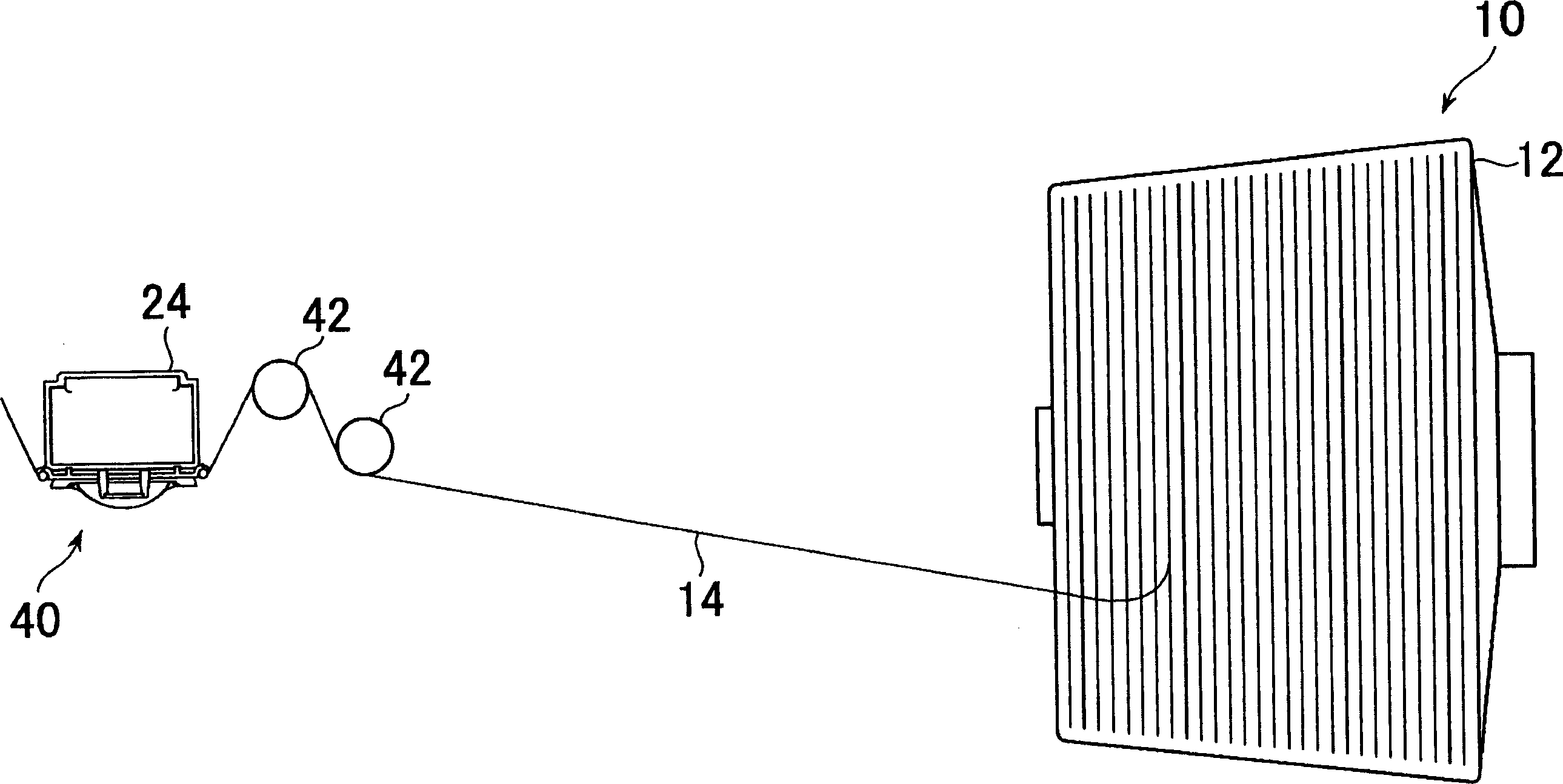

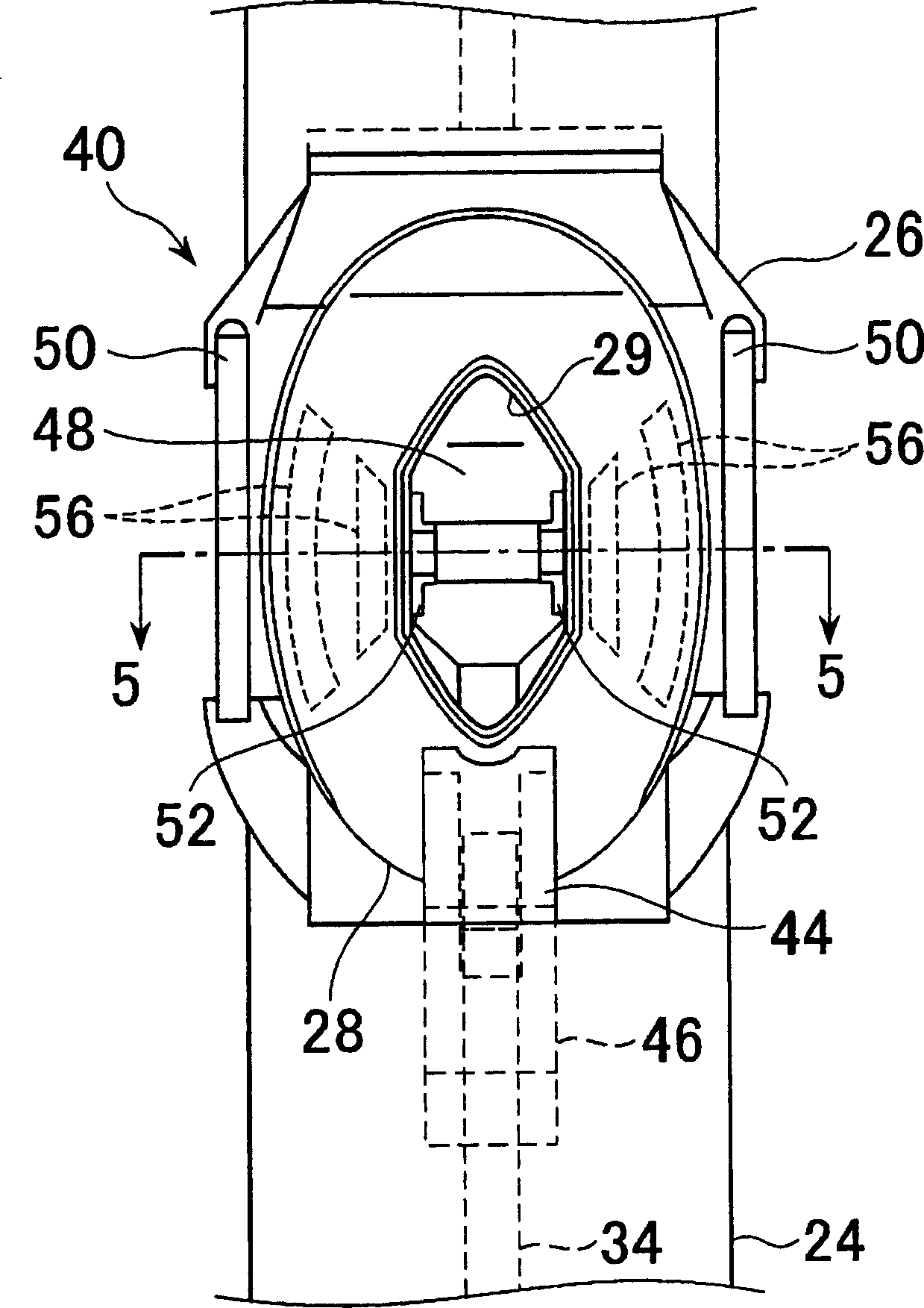

[0048] refer to Figure 2 to Figure 5 , braking device 40 with Figure 18 The shown existing brake device 22 is the same, including: a brake main body 26 installed on the combination rod 24; The brake plate 28 on the front side of 26.

[0049] The stopper plate 28 has a hole 29 in the center. The hole 29 has an elliptical shape in the illustrated example, but may be formed in an appropriate shape.

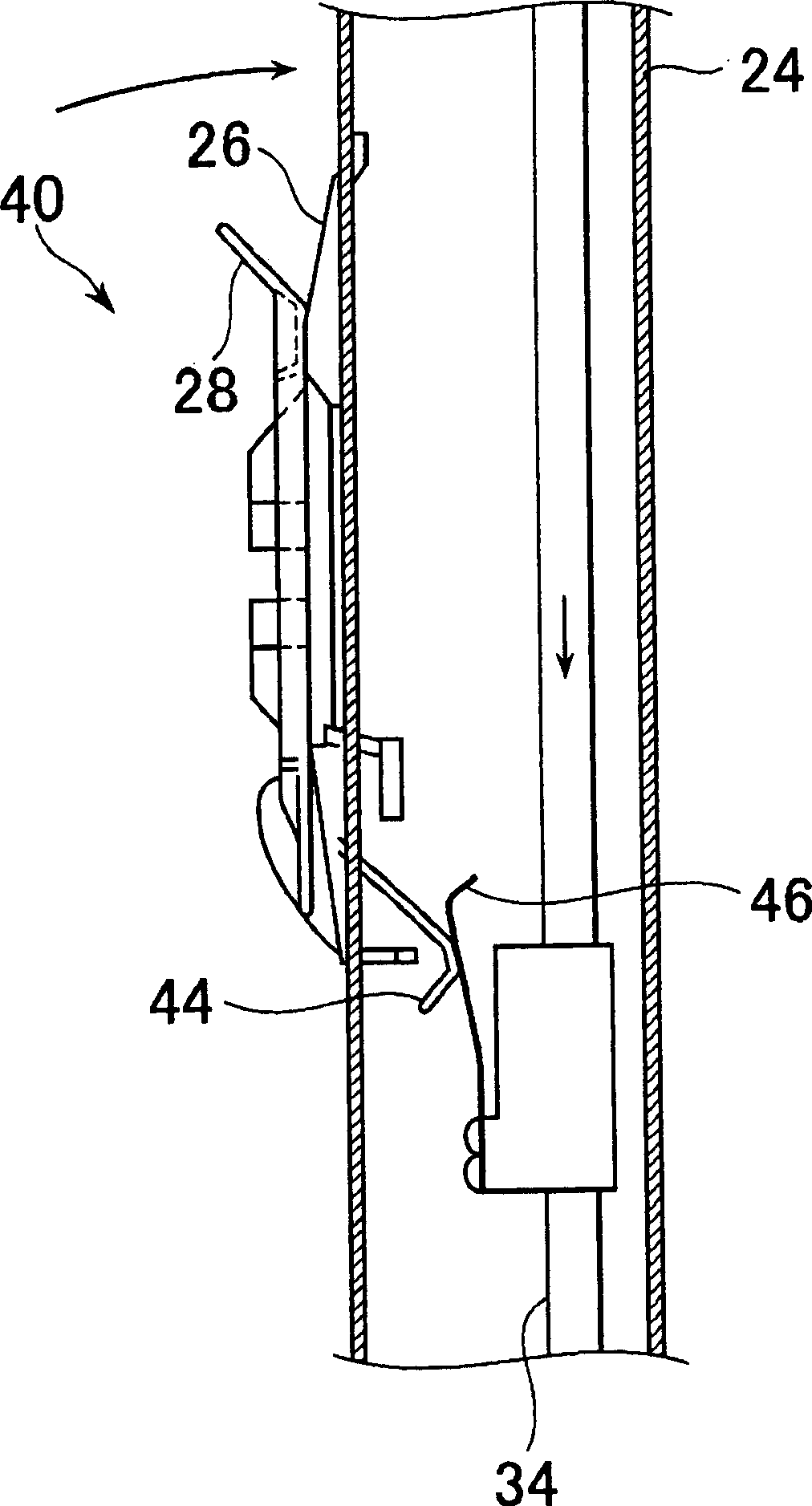

[0050] The lower end of the stopper plate 28 is pivotally connected to the lower end of the stopper body 26 , and the plate cam 44 is integrally formed at the lower end. The leaf spring 46 is attached to the rod 34 so as to be able to move up and down simultaneously with the rod 34 .

[0051] When the lever 34 descends, the plate cam 44 comes into contact with the plate spring 46 , and the plate spring 46 presses the stopper plate 28 toward one side. Thus, if image 3 The brake pads 28 are shown closed.

[0052] When the lever 34 rises, the plate cam 44 is released from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com