Residual hydrogen-storage account measuring method of hydrogen-storage container

A hydrogen storage container and residual capacity technology, applied in the field of hydrogen storage container hydrogen measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

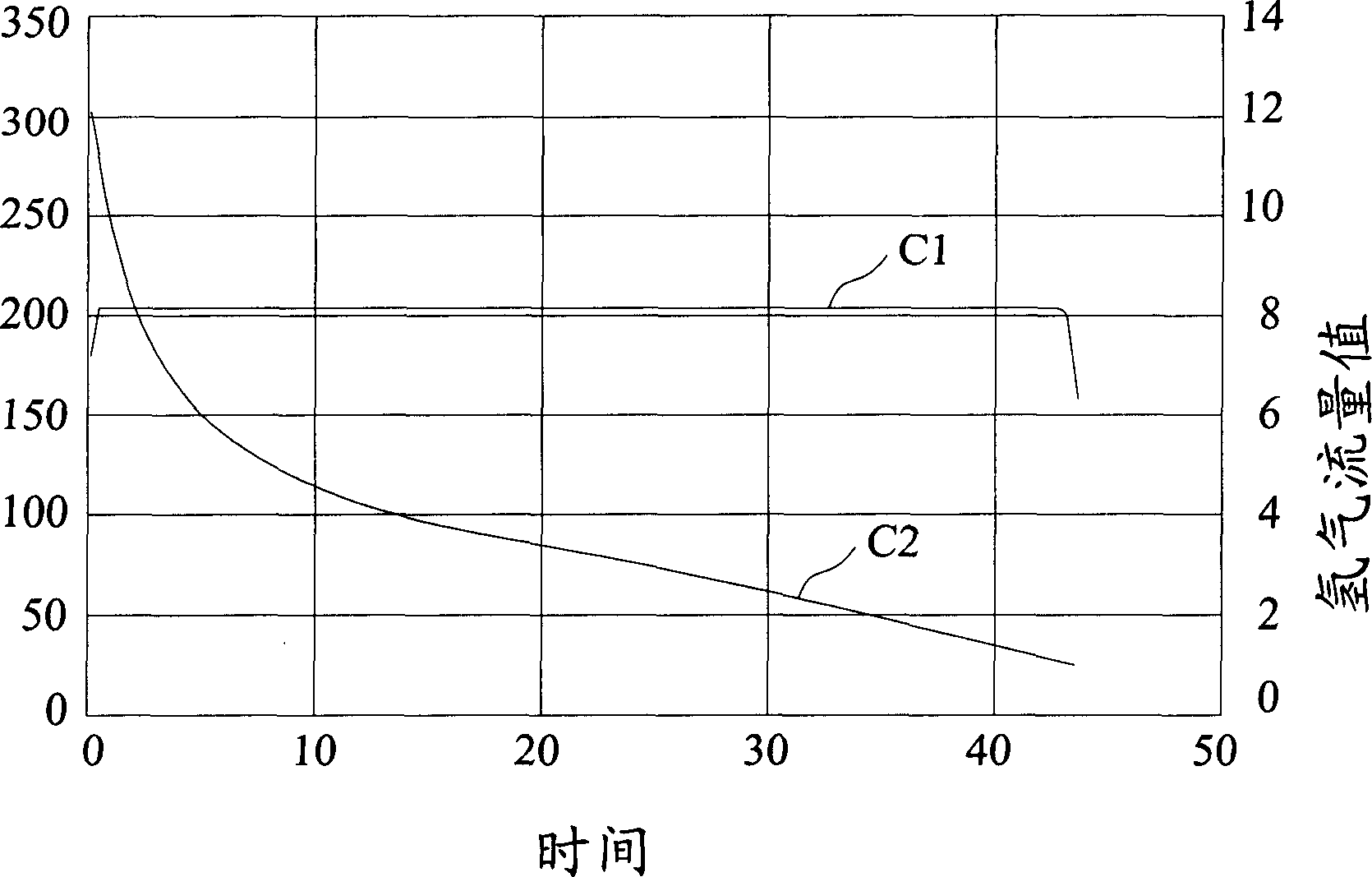

[0039] Before discussing the method of measuring the amount of hydrogen available in the hydrogen storage container, it is necessary to understand the change of the hydrogen capacity of the hydrogen storage container under real use conditions. The experimental method to meet this requirement is to dehydrogenate the hydrogen storage container that completes the hydrogen charging operation according to the fixed hydrogen charging conditions at various operating temperatures, according to the hydrogen pressure and the minimum hydrogen flow required by the application system. And use the mass flow rate to measure the hydrogen discharge capacity of the hydrogen storage container to obtain the dynamic hydrogen discharge characteristic curve (such as image 3 shown), wherein the curve C1 represents the hydrogen flow value curve, and the curve C2 represents the hydrogen pressure value curve. From this, the effective hydrogen discharge capacity at different operating temperatures can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com