Making process of thin wall stainless steel ring

A processing method, stainless steel technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of insufficient strength of parts, large environmental pollution, and limited effective service life of decorative rings, etc., to achieve long service life and high strength of products High, bright appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A processing method of a stainless steel thin-walled decorative ring is carried out according to the following steps:

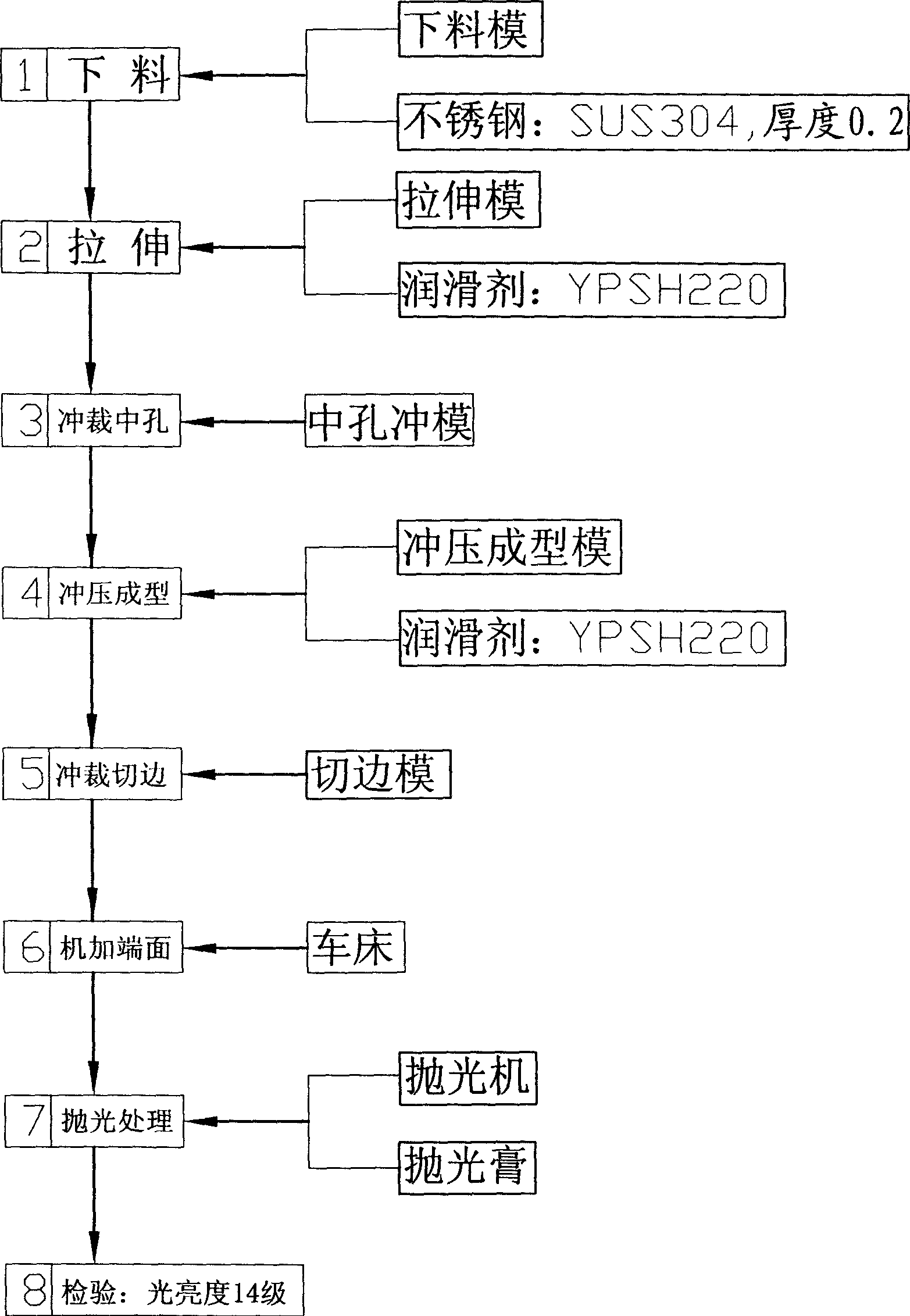

[0032] as attached figure 1 Shown:

[0033] Step 1, selected stainless steel sheet as raw material;

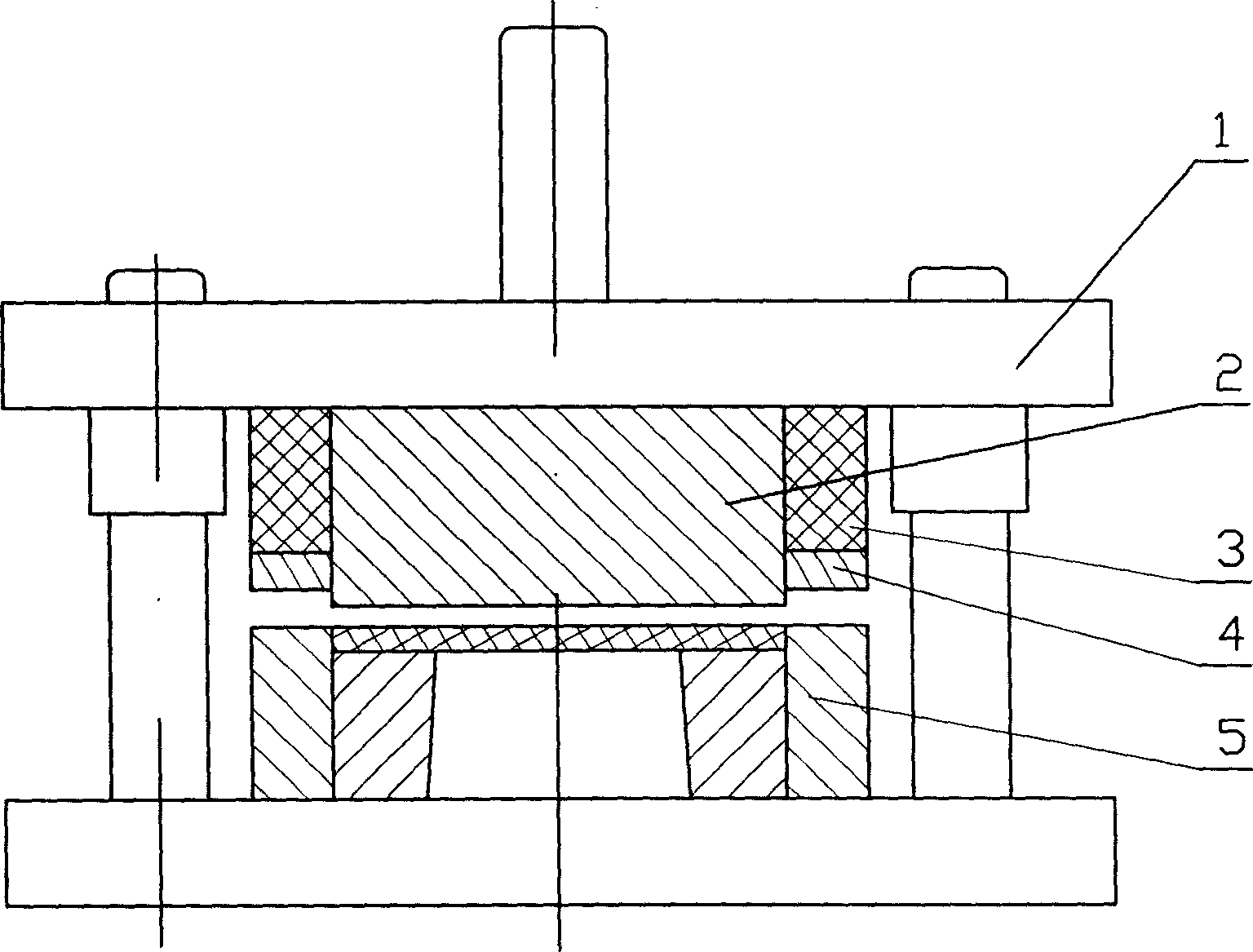

[0034] as attached figure 2 Shown:

[0035] Step 2, stamping the stainless steel sheet with a blanking die to generate a stainless steel sheet;

[0036] Compared with the common mould, the blanking mold is a ball guide mold, the concave mold of the blanking mold is located directly below the punch, the concave mold is cylindrical, the punch is cylindrical, and the cylindrical convex The cross-sectional dimension of the mold is about smaller than that of the cylindrical concave mold, and the gap is the thickness of the stainless steel sheet. Both the concave mold and the convex mold are Cr12 material molds or T10 material molds.

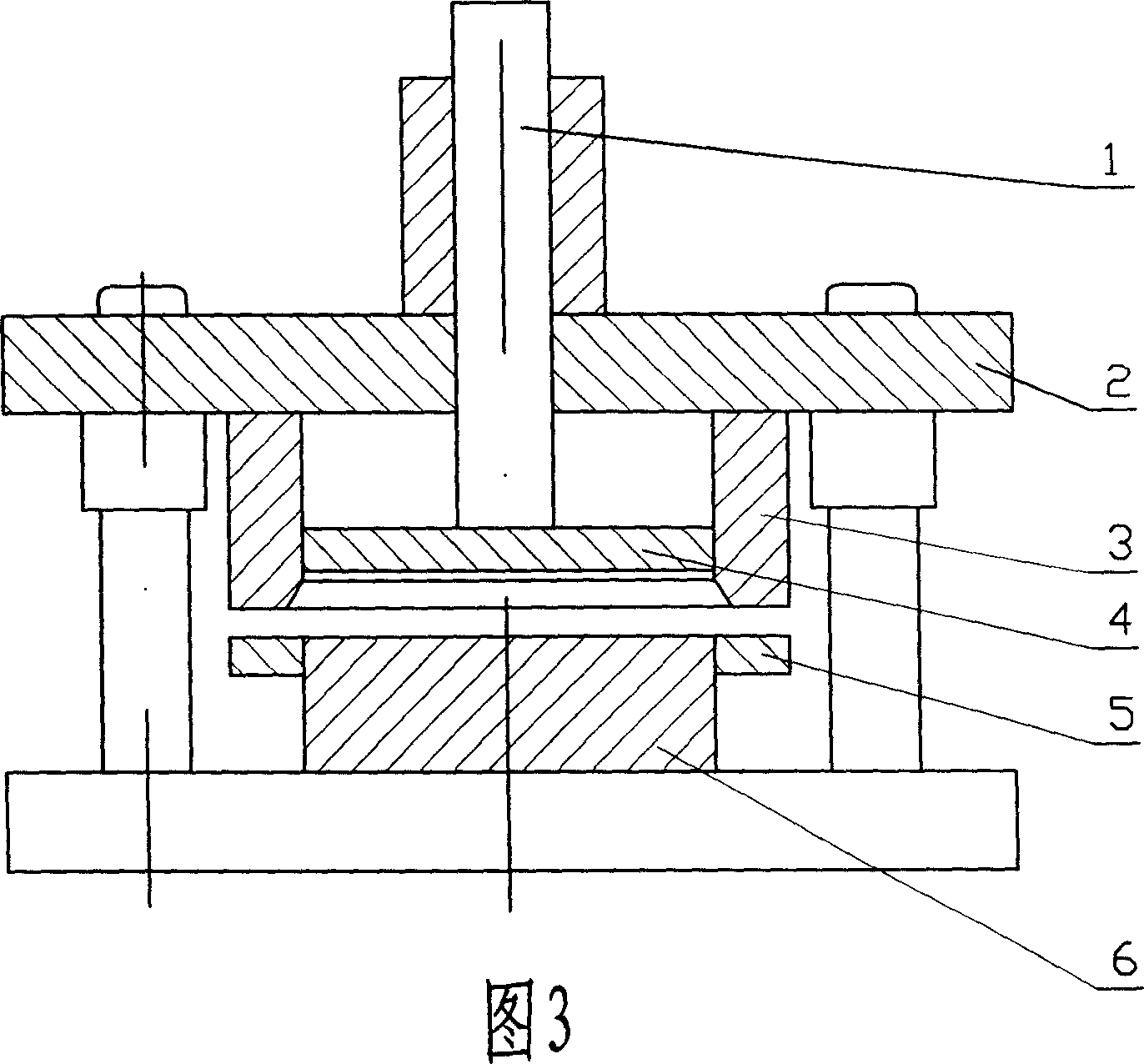

[0037] As shown in Figure 3:

[0038] Step 3, using a stretching die to stretch the edge of the stainless steel sheet...

Embodiment 2

[0056] A processing method of a stainless steel thin-walled decorative ring is carried out according to the following steps:

[0057] as attached figure 1 Shown:

[0058] Step 1, selected stainless steel sheet as raw material;

[0059] as attached figure 2 Shown:

[0060] Step 2, stamping the stainless steel sheet with a blanking die to generate a stainless steel sheet;

[0061] Compared with the common mould, the blanking mold is a ball guide mold, the concave mold of the blanking mold is located directly below the punch, the concave mold is cylindrical, the punch is cylindrical, and the cylindrical convex The cross-sectional dimension of the mold is about smaller than that of the cylindrical concave mold, and the gap is the thickness of the stainless steel sheet. Both the concave mold and the convex mold are Cr12 material molds or T10 material molds.

[0062] As shown in Figure 3:

[0063] Step 3, using a stretching die to stretch the edge of the stainless steel sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap