Exhaust silencer of internal combustion engine

A technology for exhaust mufflers and internal combustion engines, which is applied in the direction of machines/engines, noise reduction devices, mechanical equipment, etc., and can solve problems such as increased noise, increased resistance, and increased exhaust speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with examples (accompanying drawings), but does not limit the present invention.

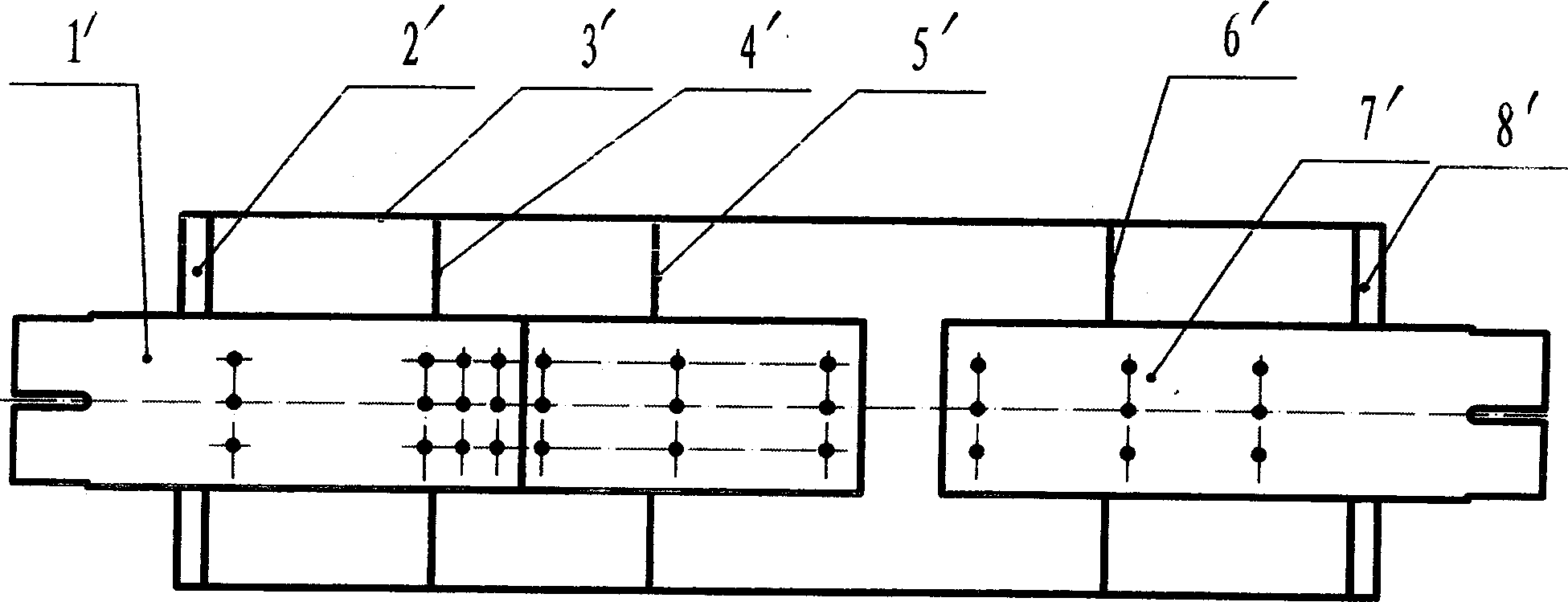

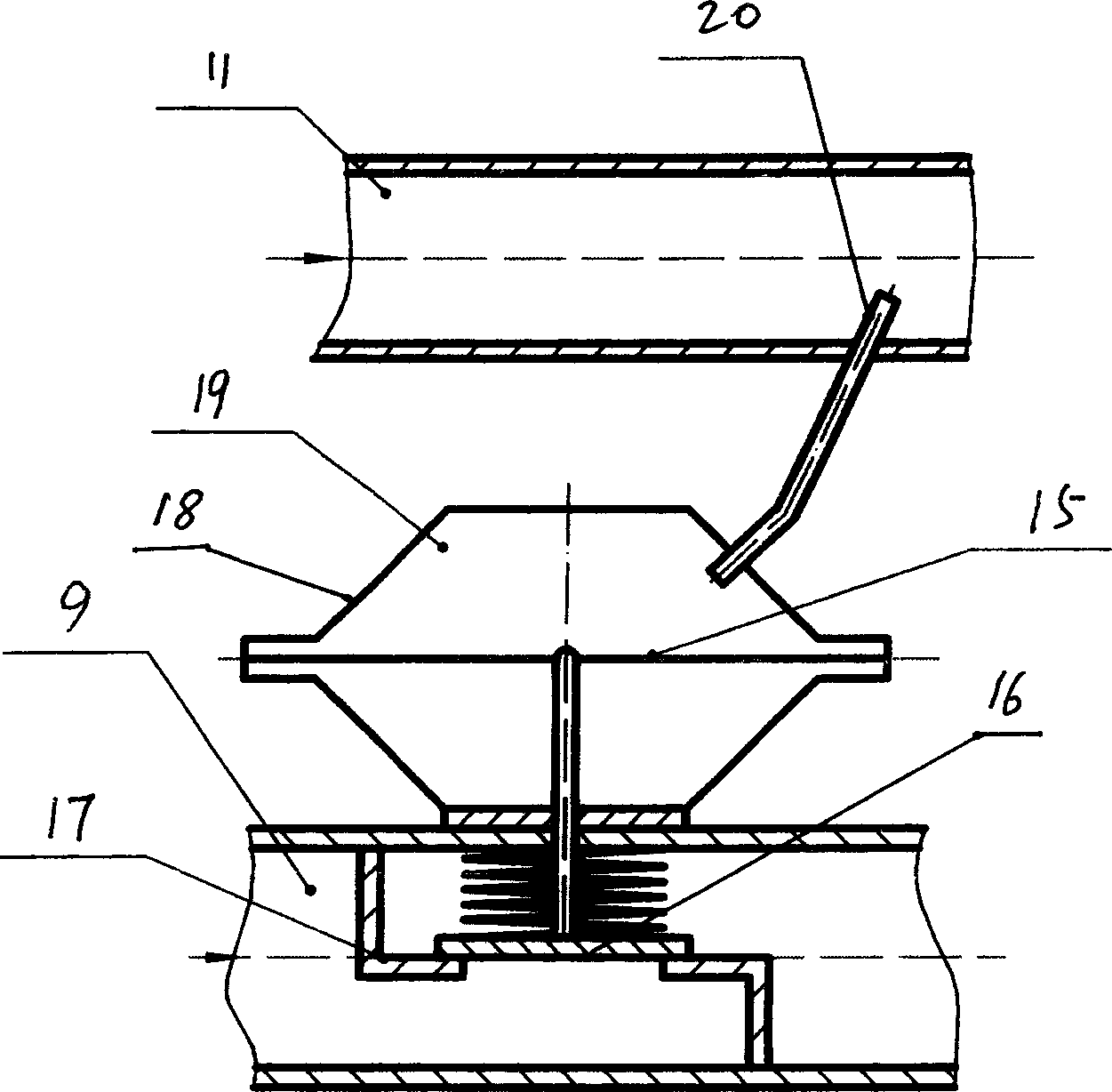

[0029]As shown in Figures 2, 3, and 4, the internal combustion engine exhaust muffler of the present invention includes a housing 2 made of front and rear end covers and a hollow cylinder, and a pipe wall disposed in the inner cavity of the housing 2 is processed with The intake muffler pipe 4 with multiple air holes and the exhaust muffler pipes 9 and 11 with multiple air holes processed on the two pipe walls, the inner cavity of the housing is provided with partitions 3, 6, 7 in sequence from front to back. It is divided into four chambers II, I, III, and IV. Air holes 12 and 14 communicating with the front and rear chambers are opened on the partitions 3 and 7. The closed end of the air intake muffler pipe 4 passes through the front end in turn. The through holes processed on the cover 1 and the dividing plate 3 enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com