Heat-pipe cooling type grinding roller

A cooling type, heat pipe technology, applied in grain processing, etc., can solve the problems of dangerous maintenance, inconvenience, safety of processed materials such as leaking, leaking, leakage, etc., and achieve the effect of good cooling effect, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

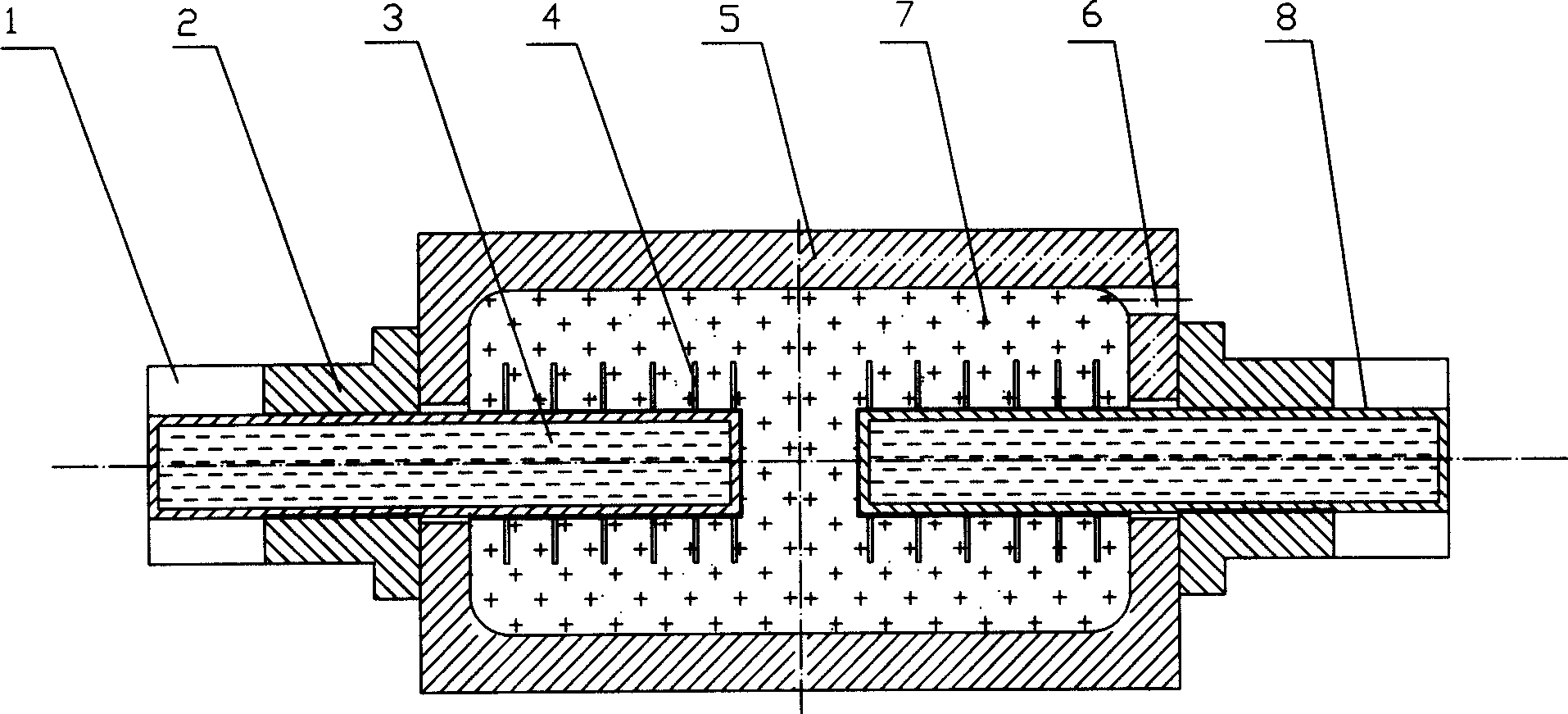

[0019] like figure 1 As shown, a heat pipe cooling grinding roller includes: a hollow roller body 5, a hollow shaft head 2 connected at both ends of the roller body, and communicates with the inner cavity of the hollow roller body 5, and the inner hole of the hollow shaft head 2 is in line with the horizontal The excircle of rotary heat pipe 8 fits closely, and the heated end of heat pipe stretches into the inner chamber of roller body, and the radiating end of heat pipe stretches out the axle head outside, and the inner cavity of hollow roller body is annotated with heat transfer medium 7.

[0020] There are two horizontally rotating heat pipes 8, the outer circles of which are closely matched with the inner holes of the two hollow shaft heads respectively.

[0021] In order to improve the heat absorption effect, the heat receiving end of the heat pipe is provided with heat absorption fins 4 ; in order to improve the heat dissipation effect, the heat dissipation end of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com