Self-compensation high-temp resistance prefabricated direct-buried heat insulation pipe

A thermal insulation pipe and high temperature resistant technology, applied in the direction of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of thermal insulation failure, low heat dissipation loss, water leakage and seepage, etc., to reduce civil construction and construction, low heat dissipation loss, easy to use The effect of production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

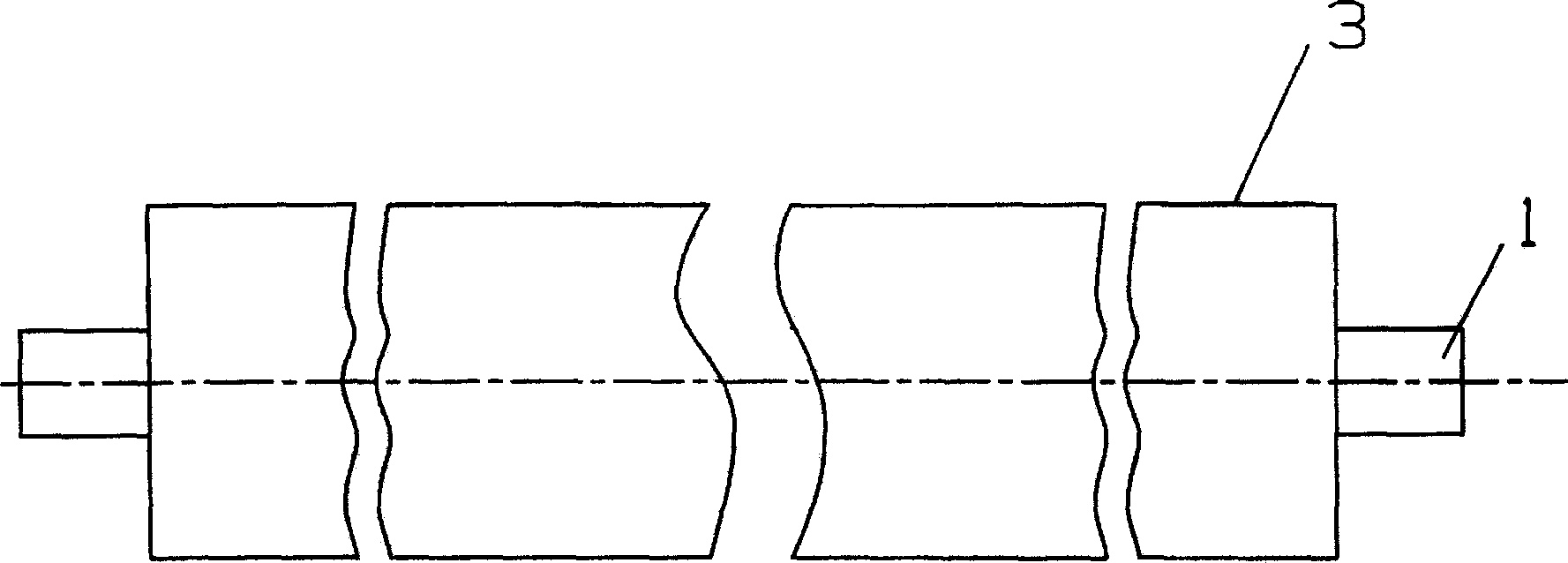

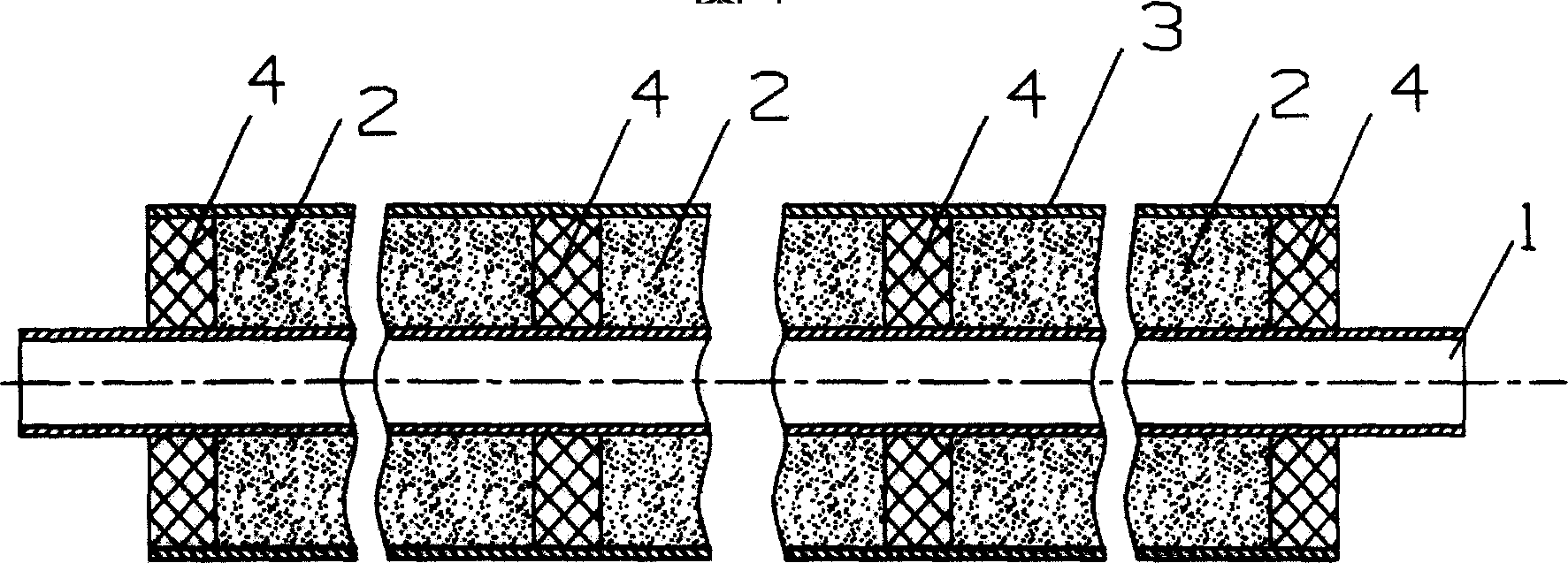

[0026] Embodiment 1, as attached figure 1 and 2 As shown, the self-compensating high-temperature resistant prefabricated direct-buried thermal insulation pipe includes a core pipe 1, a heat insulating layer 2 and an outer protective casing 3. There is a heat insulating layer 2 outside the core pipe 1, and an outer protective casing 3 outside the heat insulating layer 2. , there is not less than one hard heat insulating support ring 4 between the core tube 1 and the outer protective sleeve 3; as attached figure 1 and 2 As shown, the outer protective sleeve 3 adopts a flat-walled outer protective tube. When in use, due to the special structure of the invention, it has a "self-compensation" function when it expands at high temperature, so the structure will not be damaged, so the invention has a high heat preservation effect.

Embodiment 2

[0027] Embodiment 2, as attached Figures 1 to 4 As shown, the difference between the self-compensating high-temperature resistant prefabricated direct-buried thermal insulation pipe and the embodiment 1 is that the outer protective casing 3 of the embodiment 2 adopts a corrugated outer protective pipe.

Embodiment 3

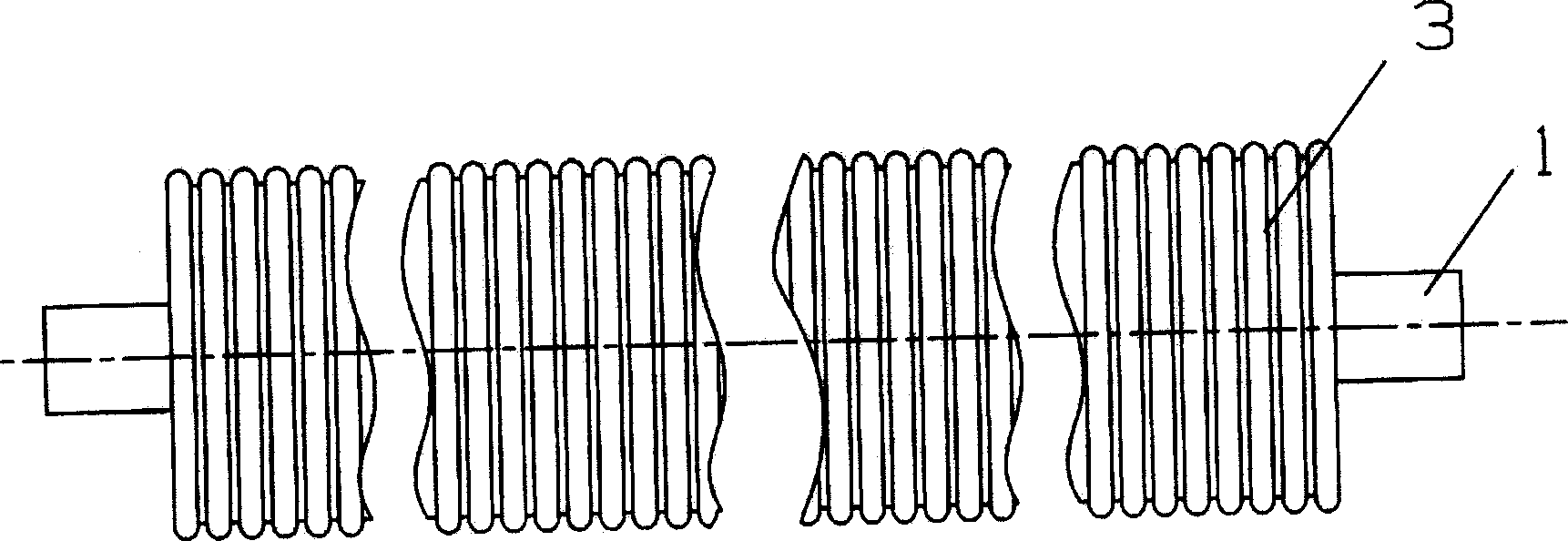

[0028] Embodiment 3, as attached Figures 3 to 6 As shown, the difference between the self-compensating high-temperature-resistant prefabricated direct-buried thermal insulation pipe and the embodiment 2 is that the outer protection casing 3 of the embodiment 3 adopts a spiral outer protection pipe.

[0029] In the above-mentioned embodiments 1, 2 and 3: according to actual needs, the outer protective sleeve 3 can adopt the insulation pipe made of polyvinyl chloride hard plastic in the prior art or the heat preservation tube made of high-density polyethylene hard plastic. Tube or insulation pipe made of glass fiber reinforced plastic material or insulation pipe made of metal material, heat insulation layer 2 can adopt hard insulation material in the prior art, semi-hard insulation material, soft insulation material, elastic foam insulation material, inorganic One or more of porous thermal insulation materials, organic porous thermal insulation materials, inorganic-organic comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com