Dyes for anisotropic dye films, dye compositions for anisotropic dye films, anisotropic dye films and polarizing elements

A dye composition, anisotropic technology, applied in the direction of polarizing elements, azo dyes, organic dyes, etc., can solve the problems of insufficient heat resistance or light resistance, poor yield of bonded anisotropic dye film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0278] Under stirring, 10 parts of dyes (I-31) exemplified below and 0.2 parts of nonionic surfactant EMULGEN 109P (produced by Kao Corporation) were dissolved in 89.8 parts of water to obtain a dye composition for anisotropic dye film:

[0279]

[0280] On the other hand, prepare a base material, this base material comprises glass base material (75mm * 25mm, thickness 1mm) and polyimide alignment film (polyimide film thickness: about 800 Ȧ) formed on it by silk printing , and pre-rubbed with a cloth. On the substrate thus prepared, the aforementioned dye composition for anisotropic dye film was coated with a bar coater ("No. 3" manufactured by Tester Sangyo Co., Ltd.), followed by natural drying to obtain a film thickness of about An anisotropic dye film of 0.4 μm.

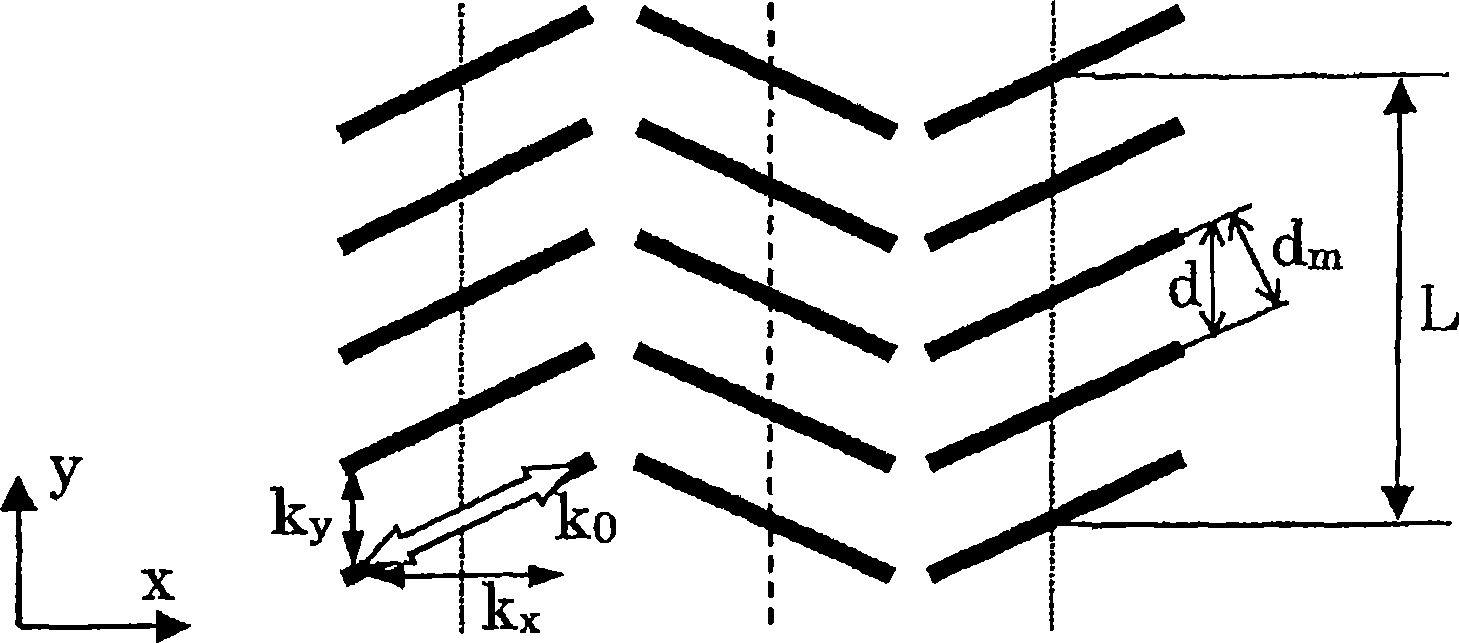

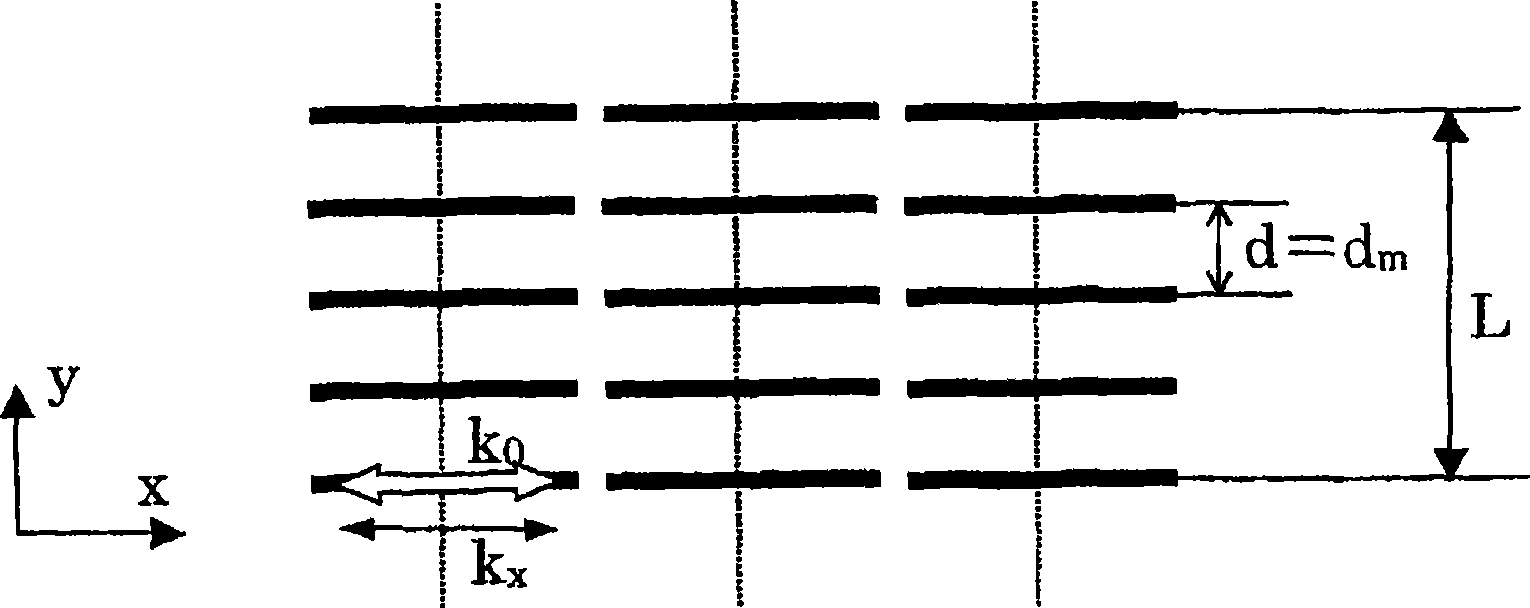

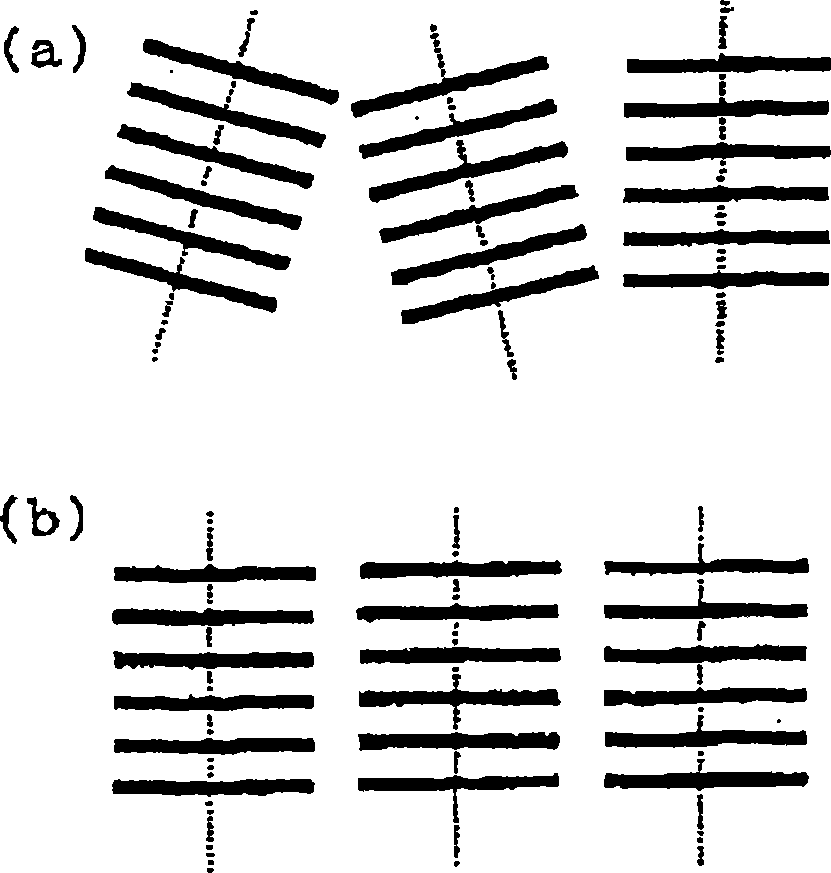

[0281] The X-ray diffraction curves and in-plane vibration curves of the obtained anisotropic dye films are shown in Figure 4 with Figure 5 middle. Figure 4 Shows the results of in-plane measurement fro...

Embodiment 2

[0285] Under stirring, 10 parts of the following exemplified dye (II-15) were dissolved in 90 parts of water to obtain a dye composition for anisotropic dye film:

[0286]

[0287] In the same manner as in Example 1 except using a bar coater (“No. 2” produced by Tester Sangyo Co., Ltd.), the glass substrate on which the polyimide alignment film was formed was coated with The dye composition for the anisotropic dye film was spread, followed by natural drying to obtain an anisotropic dye film.

[0288] The obtained anisotropic dye film was tested for its molecular lamination period, lamination length, orientation degree of molecular lamination axis, and dichromatic ratio, and the results are shown in Table 1.

[0289] Table 1 demonstrates that the anisotropic dye film of this example has a molecular arrangement suitable for expressing a dichroic ratio and has a high dichroic ratio.

Embodiment 3

[0291] Under stirring, 8 parts of the following exemplified dye (I-1) were dissolved in 92 parts of water to obtain a dye composition for anisotropic dye film:

[0292]

[0293] The anisotropic dye was coated on a glass substrate on which a polyimide alignment film was formed in the same manner as in Example 1, except that a coater (manufactured by Imoto Manufacturing Co., Ltd.) with a gap of 10 μm was used. The dye composition for the film, followed by natural drying, thereby obtaining an anisotropic dye film.

[0294] The obtained anisotropic dye film was tested for its molecular lamination period, lamination length, orientation degree of molecular lamination axis, and dichromatic ratio, and the results are shown in Table 1.

[0295] Table 1 demonstrates that the anisotropic dye film of this example has a molecular arrangement suitable for expressing a dichroic ratio and has a high dichroic ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com