Electromagnet for controlling shuttle box of weft machine

A shuttle box and electromagnet technology, which is applied in the field of electromagnets, can solve the problems of inaccurate positioning of the shuttle box, insufficient suction force, and increase of magnetic flux, etc., achieves obvious effects of magnetic flux gain, solves insufficient suction force, and increases magnetic flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

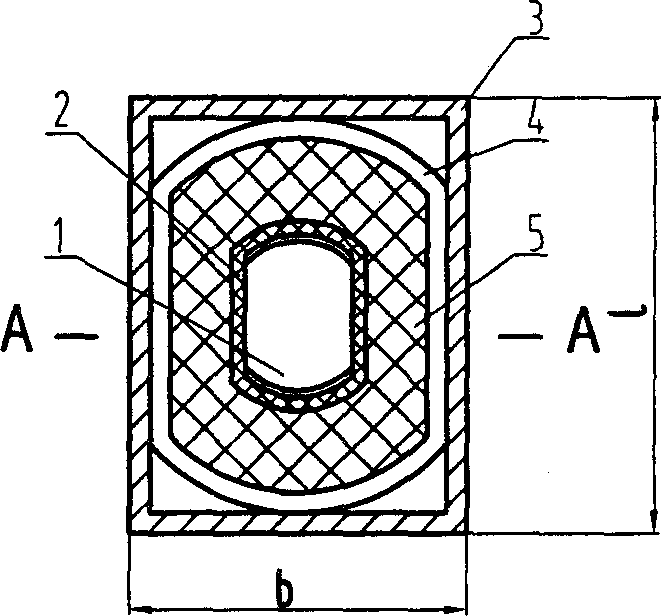

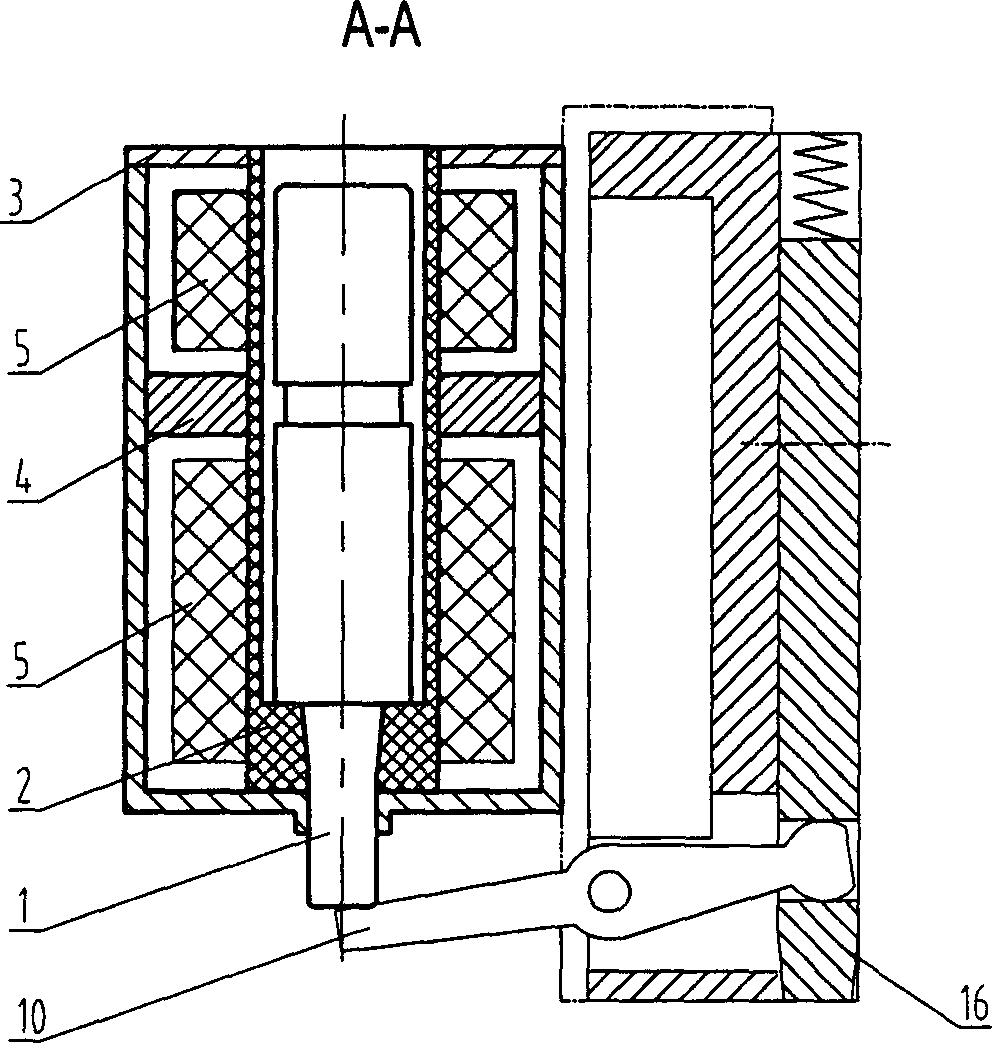

[0016] A specific embodiment of the device of the present invention see figure 1 , figure 2 . The cross section of the armature housing 3 is rectangular, with a side width b=25mm and the other side width l=32mm. The cross section of the armature 1 is a drum shape, and the cross sections of the magnetic steel 4, the skeleton 2 and the coil 5 are similar drum shapes. The skeleton 2 is plugged on the outside of the armature 1, and the magnetic steel 4 is plugged on the skeleton 2. The armature 1, the magnetic steel 4, the skeleton 2 and the coils wound on it form a magnetic core, and the magnetic core is fixed on the armature housing 3. At the center of the inner side, and the magnetic steel 4 is in close contact with the inner side of the armature housing 3 to form a closed magnetic circuit.

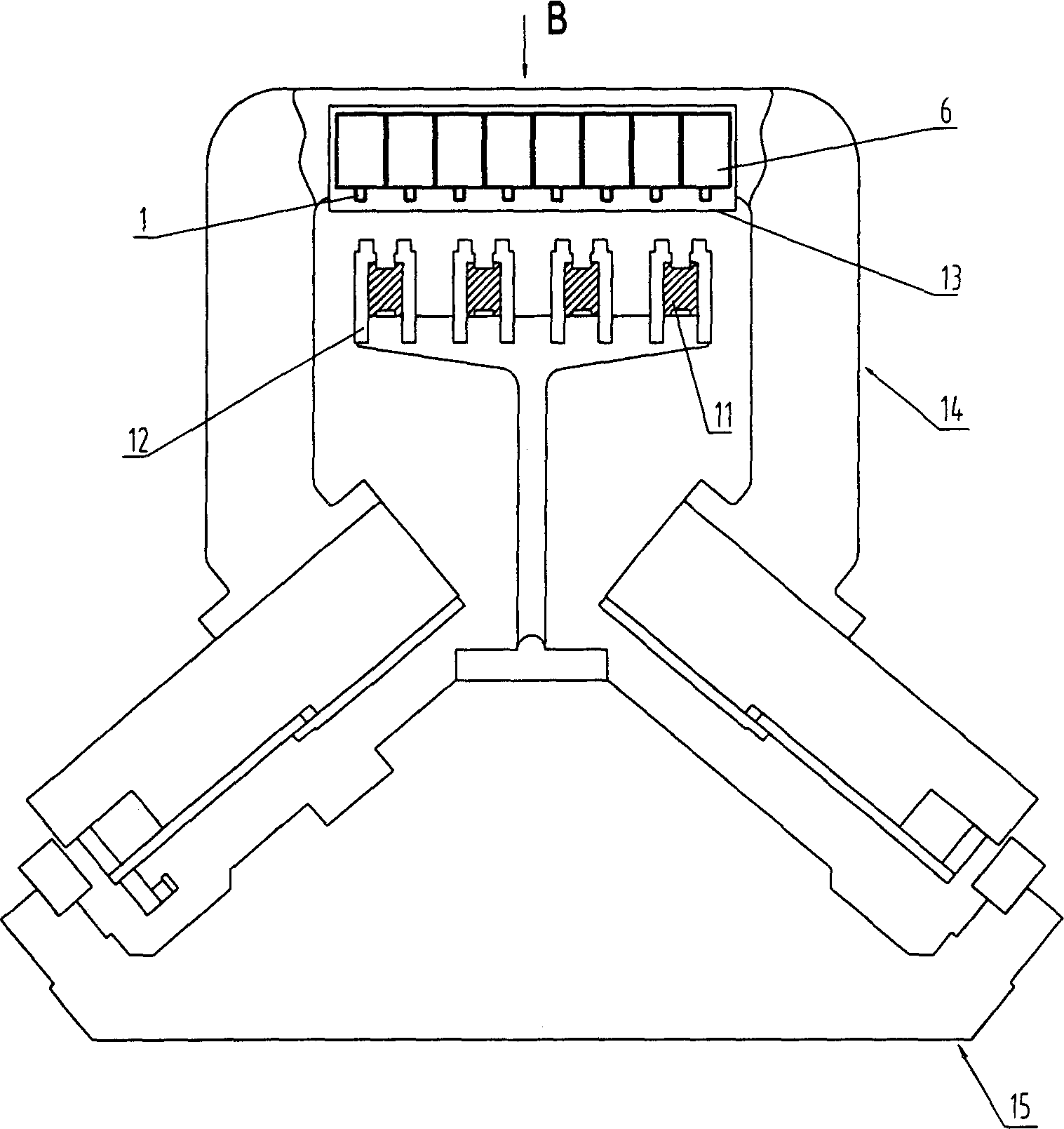

[0017] Please compare image 3 , Figure 4 , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap