Pressure servo clutch power-assisted pump

A clutch and booster pump technology, which is applied in fluid-driven clutches, clutches, non-mechanical drive clutches, etc., can solve the problems of eccentric wear, unreasonable, non-following structure, etc., and achieve the effect of easy installation, reasonable structure, and overcoming eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

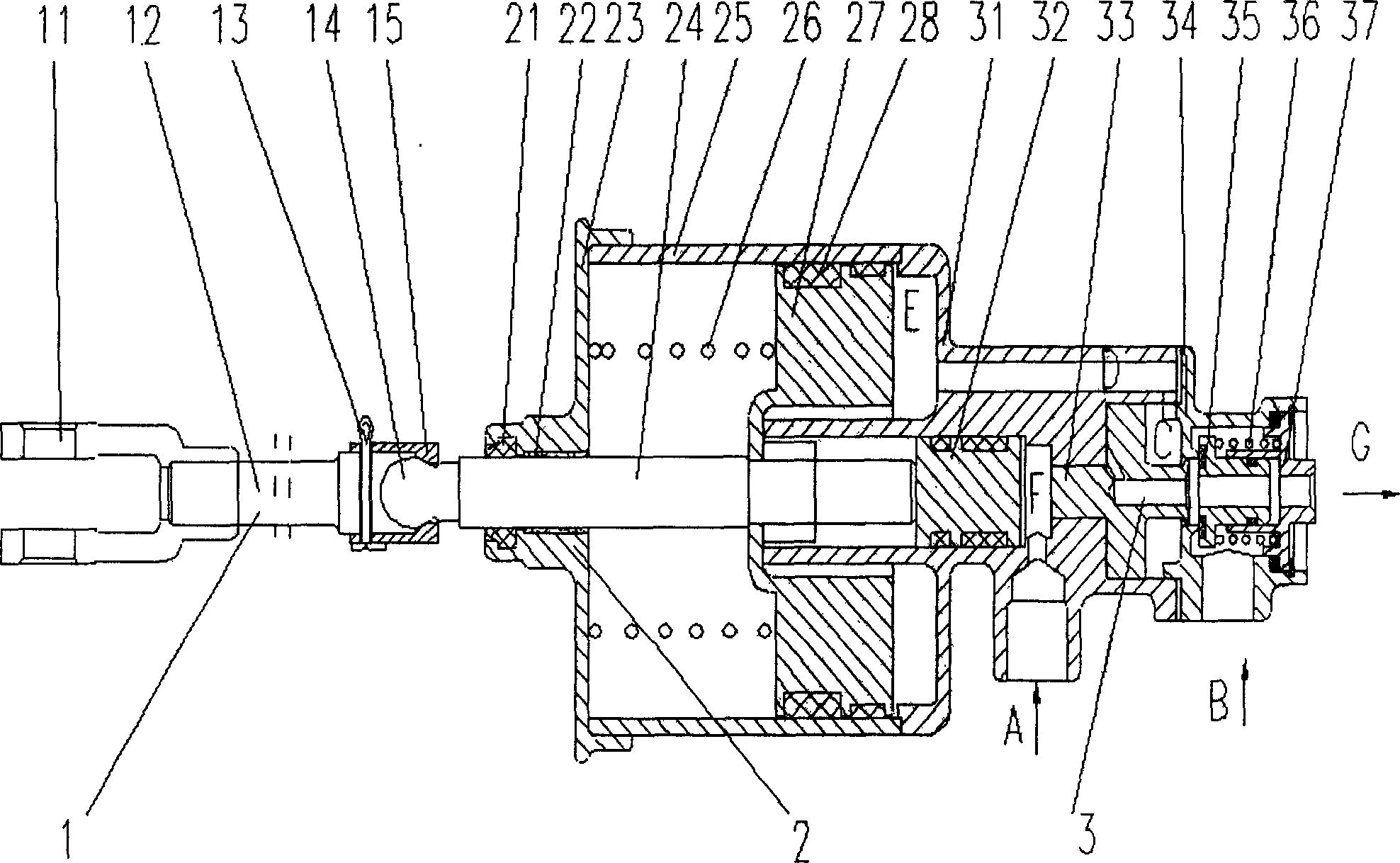

[0039] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] Specifically, it is divided into non-working state and implementation assistance state:

[0041] not working. When the driver does not step on the clutch, the device of the present invention does not work, so the oil pressure in the oil pressure chamber F is normal pressure, the oil cylinder piston 32 and the booster piston 27 are all in the return state at the right end, and the booster push rod 24 does not stretch out , the follower piston 33 is also in the return state at the left end, and the valve 35 in the small valve body 34 is compressed under the elastic force of the small spring 36, thereby cutting off the air inlet B.

[0042]Implement boost state. When the driver steps down the clutch pedal, the device of the present invention starts to work, and the hydraulic oil enters the hydraulic chamber F from the oil inlet A, and un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com