Multistep assemblied anti-settle magnetic rheological damper

A magneto-rheological damper and assembled technology, which is applied in the field of damping devices, can solve the problems that it is difficult to effectively prevent the magnetorheological fluid from settling, and the requirements for DC current sources are high, so as to prevent static settling, increase output value, and process design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

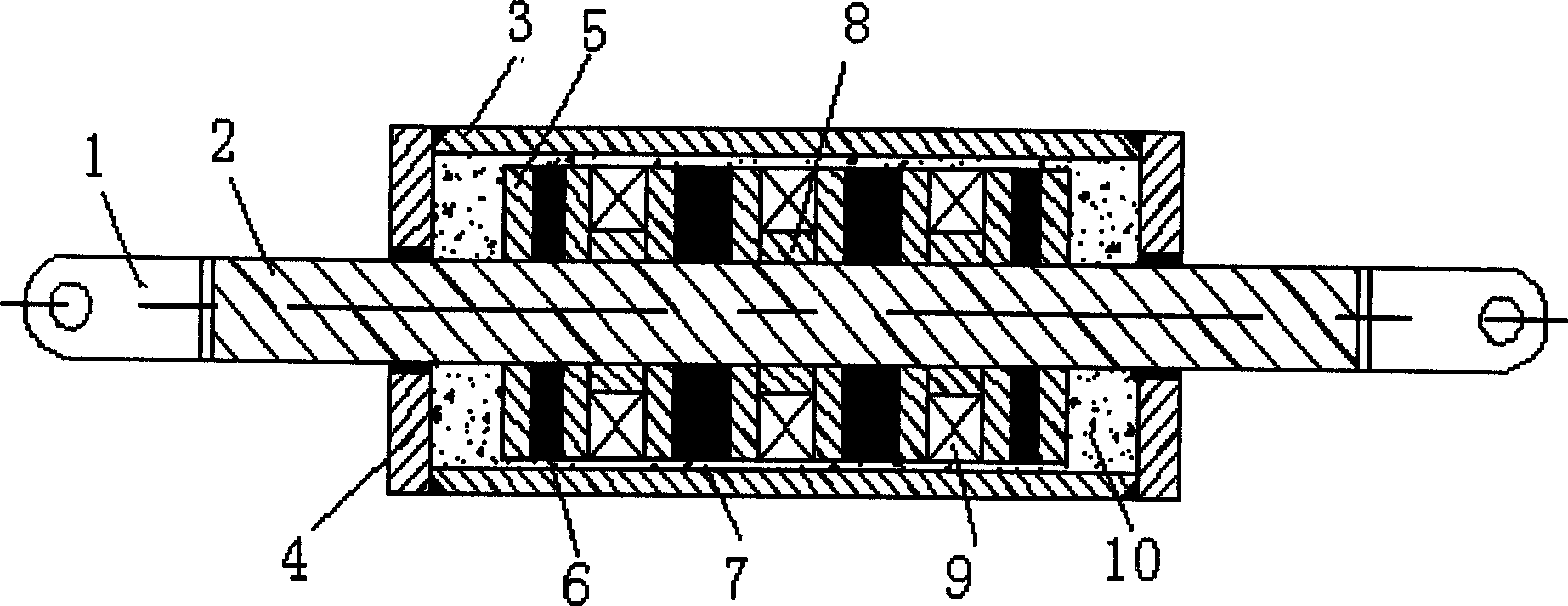

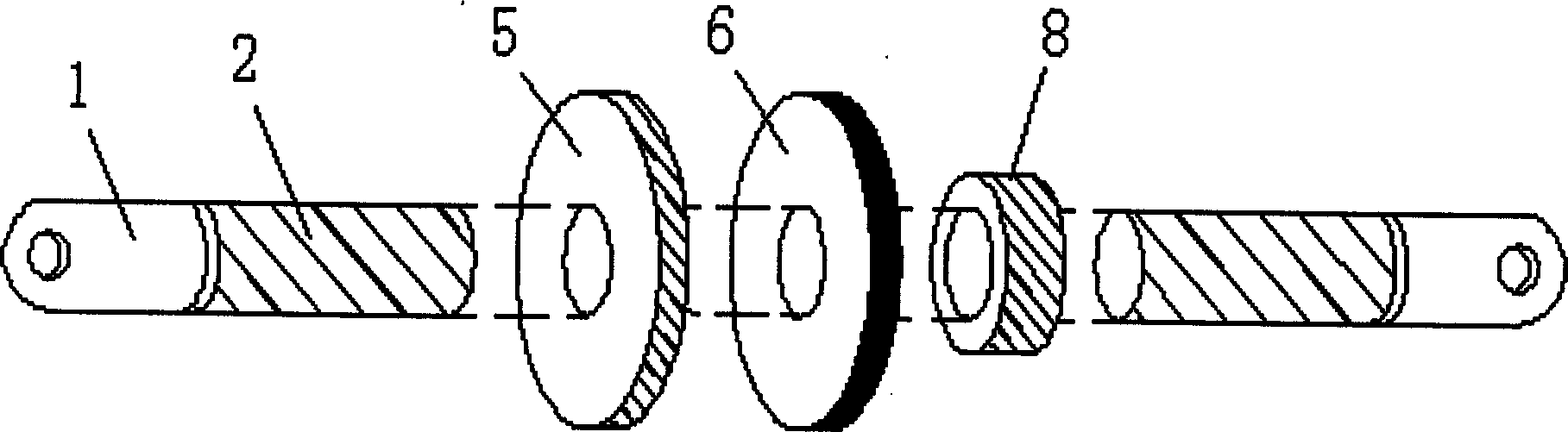

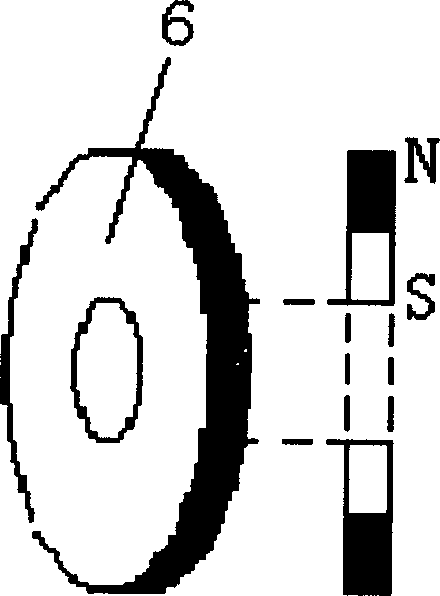

[0014] like Figure 1-3 The multi-stage assembled anti-settling magneto-rheological damper includes a cylinder 3, an end cover 4, a piston, a piston rod 2, and a throttling flow is arranged between the inner wall of the cylinder 3 and the outer wall of the piston. Road 7, the piston includes multiple groups of magnetically conductive piston disks that are sleeved on the piston rod 2 and each group is composed of two magnetically conductive piston disks 5, and the two magnetically conductive piston disks of each group of magnetically conductive piston disks There is a permanent magnet piston disc 6 set on the piston rod between them, and its magnetic strength is preferably 5000-8000 gauss. In order to increase its shear strength, its surface should have a high-strength coating, which can be zinc, nickel, etc. plating. A magnetic conduction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com