Cathode material of carbon in lithium ion battery in high capacity, and method

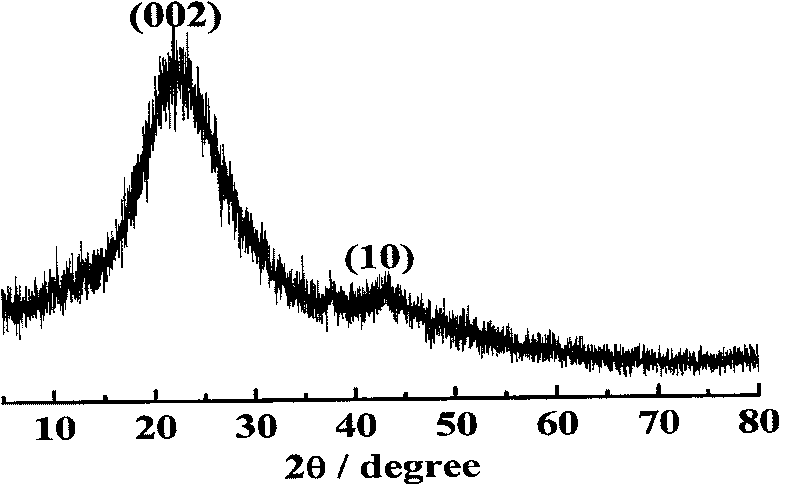

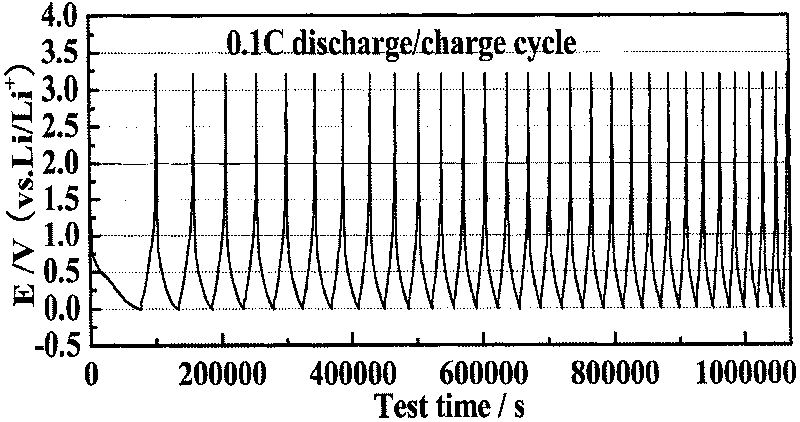

A technology of negative electrode material and lithium battery, which is applied in the field of preparation of battery negative electrode material, can solve the problems of limiting the high current charge and discharge capacity of lithium ion battery, falling off of graphite sheets, and deteriorating cycle performance of lithium ion battery, etc., and achieves low graphitization. degree, the control of the preparation process is easy, and the high current performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0015] Put the beer tank into the heating furnace, and fill the heating furnace with argon for protection. Firstly, heat the furnace at a rate of 20-50°C / min until the furnace temperature reaches 300°C±50°C, and then keep it warm so that the moisture in the wine tank can fully escape. After the moisture in the wine tank has fully escaped, this process can generally be completed after 1 hour of heat preservation. Then heat the furnace temperature at a rate of 20-50°C / min to 450°C±50°C, and keep warm to fully decompose the organic matter of distiller's grains and fully escape the generated gas. This process is generally completed in about two hours of heat preservation. Then the furnace temperature is heated at a rate of 20-50°C / min to 750°C±50°C, and then kept warm to fully carbonize the distiller's grains. This process generally takes about four hours to complete. During the entire treatment process of the aforementioned heating, the furnace should be filled with argon to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com