Method for controlling furnace temperature of heating furnace for continuous annealing

A control method and heating furnace technology, applied in heat treatment process control, heat treatment furnace, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

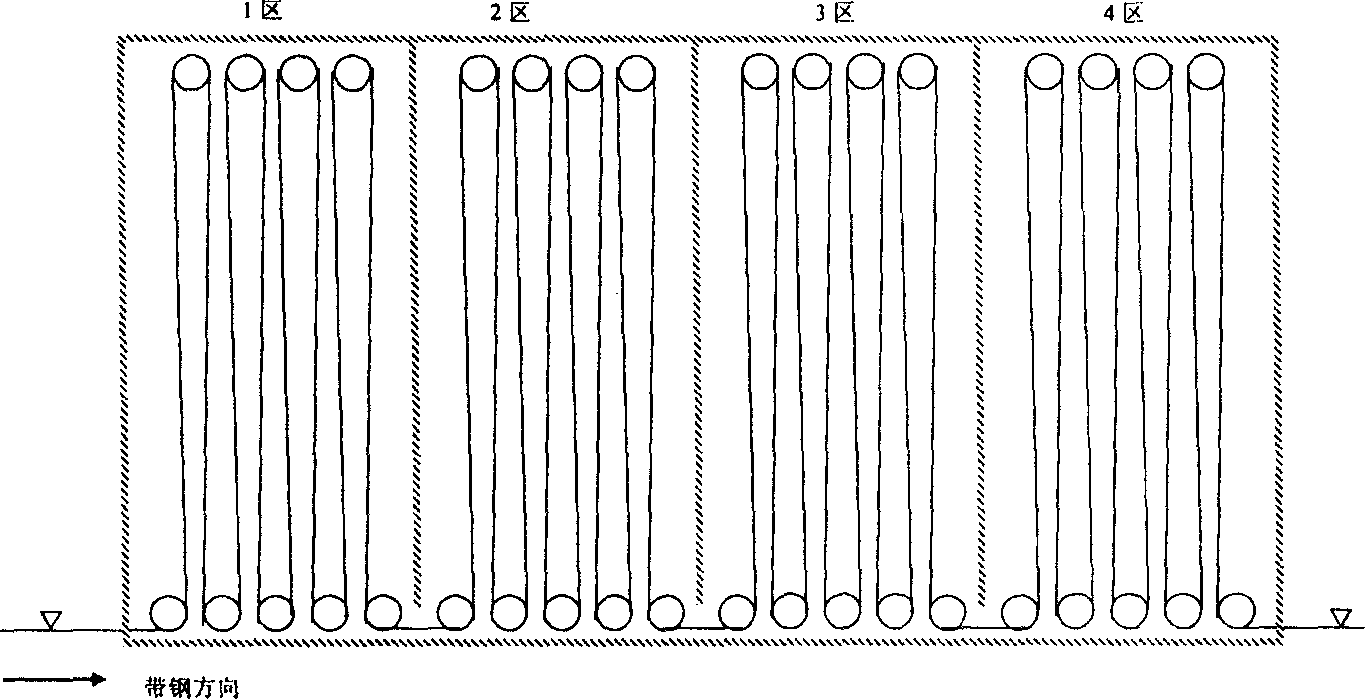

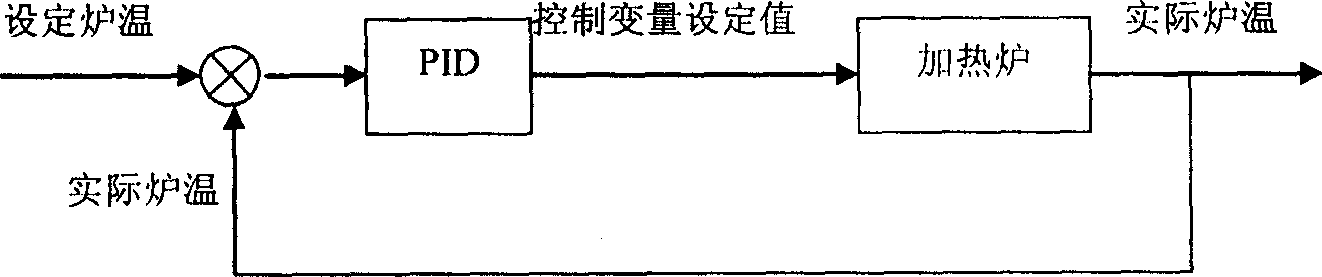

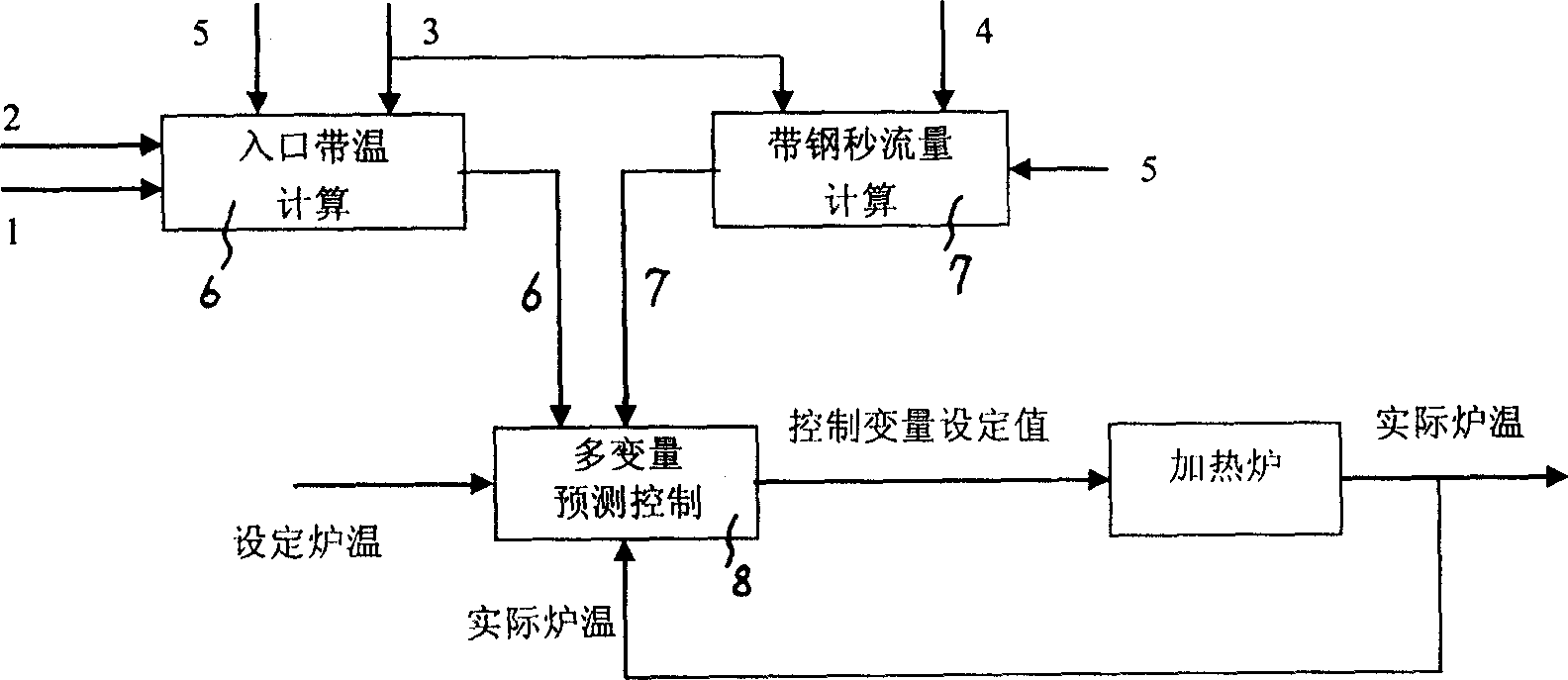

[0033] see figure 1 , image 3 , a furnace temperature control method for continuous annealing heating furnace, which takes the inlet strip temperature 6 of the furnace zone, the strip steel second flow 7 and the furnace temperature as input quantities, and uses the multivariable predictive control 8 algorithm to calculate the optimal gas at the current moment Flow increment, by adjusting the gas flow increment, the furnace temperature of the continuous annealing heating furnace is controlled, and the detailed description is as follows:

[0034] 1. Calculation of the entrance zone temperature 6, for the first furnace zone, the entrance zone temperature 6 can be measured by the zone temperature measuring instrument in front of the furnace, see figure 1 . For the follow-up furnace area, because it is very difficult to install a strip detector in the furnace, it can only be estimated based on the operating conditions of the former furnace area. The inlet zone temperature 6 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com