Large scale multi-cylinder two-stroke diesel engine

A diesel engine, a large-scale technology, applied in the direction of mechanical equipment, machines/engines, crankshafts, etc., can solve the problems of expensive engines, heavy space, and reduced efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

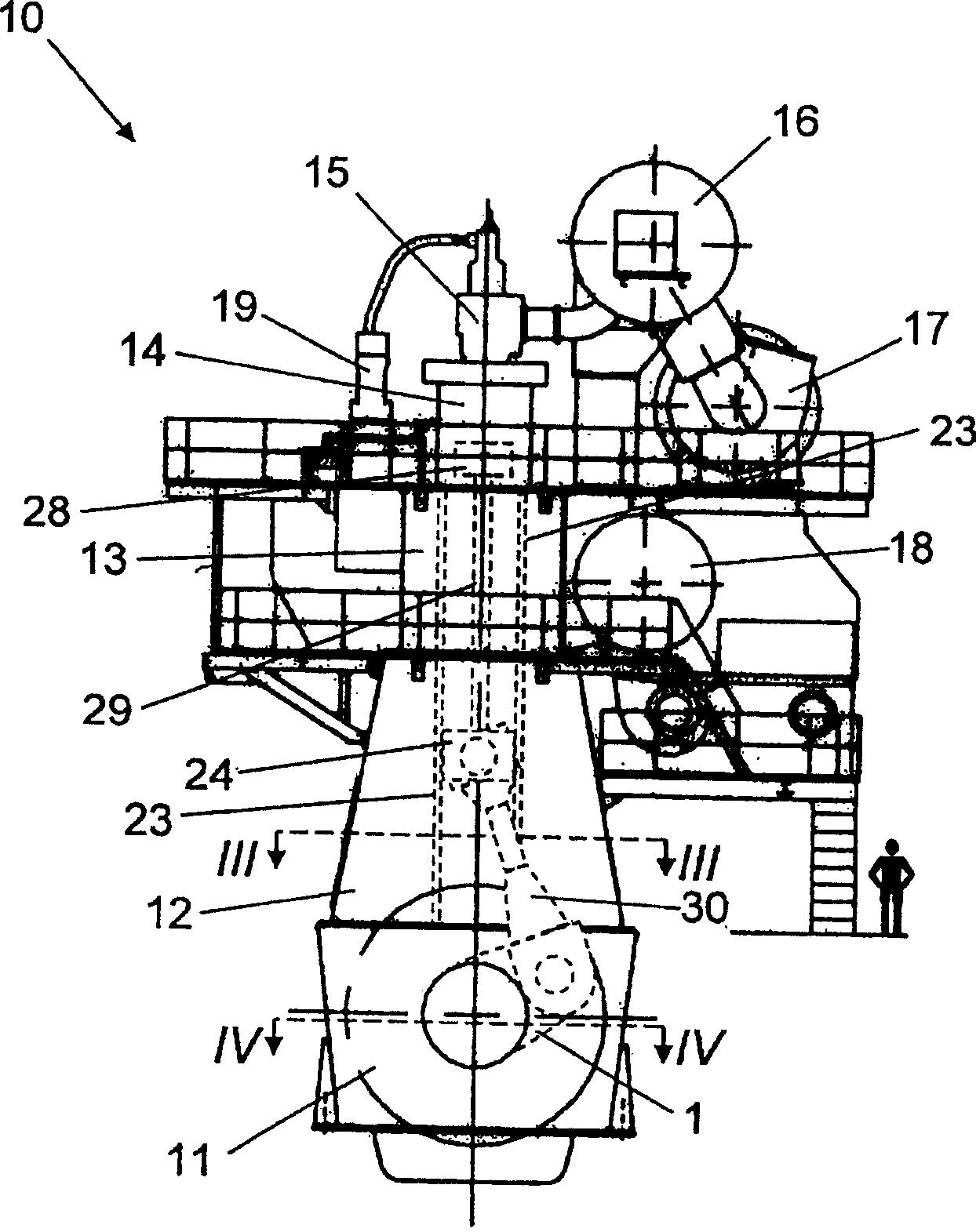

[0039] In the following detailed description, a large two-stroke diesel engine of a crosshead type will be described through a preferred embodiment.

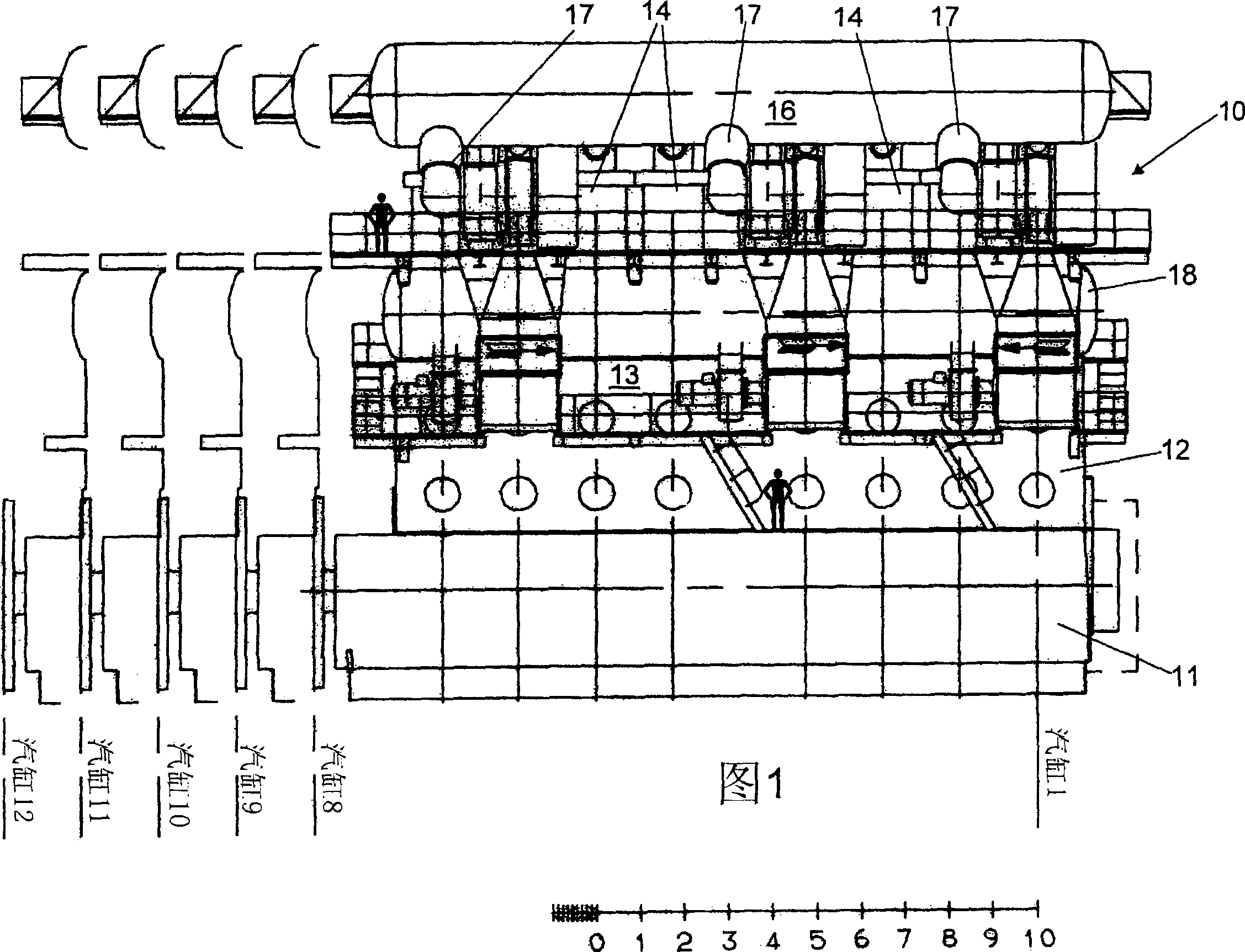

[0040] Figures 1 and 2 show a large low-speed two-stroke crosshead type tandem diesel engine 10 with a piston diameter of 98 cm, which may be a propulsion engine on a ship or a prime mover for a power plant. These engines typically have 6 to 16 cylinders arranged in a row. In Figure 1 a side view of an 8 cylinder engine 10 is depicted, with other lines showing the outlines of the 9, 10, 11 and 12 cylinder variants of the engine. A scale in meters is shown below the engine 10 to indicate the absolute dimensions of these machines, which measure between 18 meters for the 8-cylinder version and 28 meters for the 14-cylinder version.

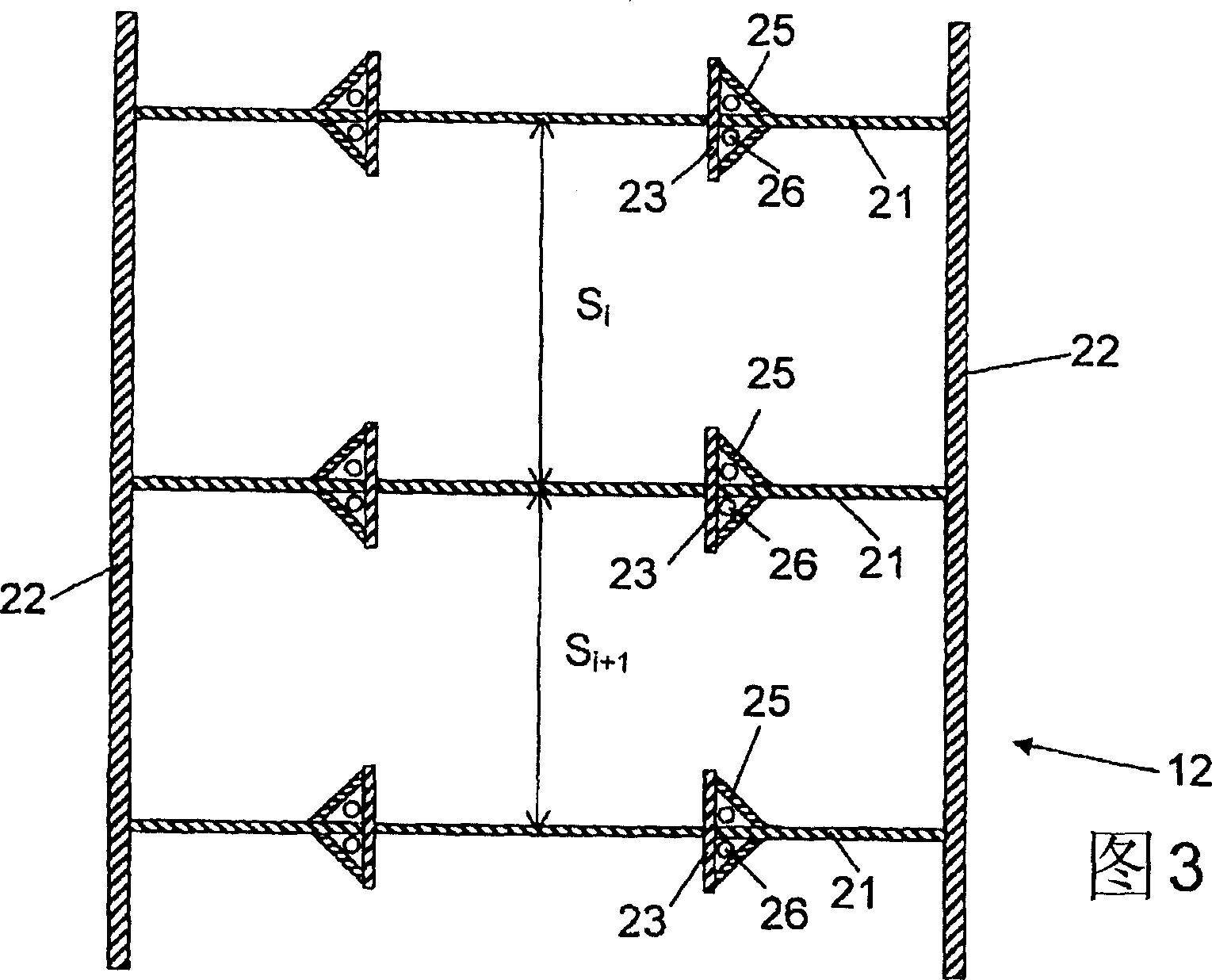

[0041] The engine is built up from a bedplate 11 with main bearings for the crankshaft 1 . The platen 11 is divided into sections of suitable dimensions according to the production equipment availabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com