Method and equipment for enriching and storing and transporting coalbed gas by using hydrate

A coalbed methane and hydrate technology, which is applied in container filling methods, gas/liquid distribution and storage, gas fuel, etc., can solve the problems of unreported enrichment of coalbed methane

Inactive Publication Date: 2006-12-06

INST OF PROCESS ENG CHINESE ACAD OF SCI

View PDF2 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the hydrate gas storage and transportation or gas separation technology reported in the literature is mainly used for natural gas and refinery gas, and the technology of coalbed methane enrichment, storage and transportation using hydrate has not been reported yet.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022]

Embodiment 2

[0024]

Embodiment 3

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

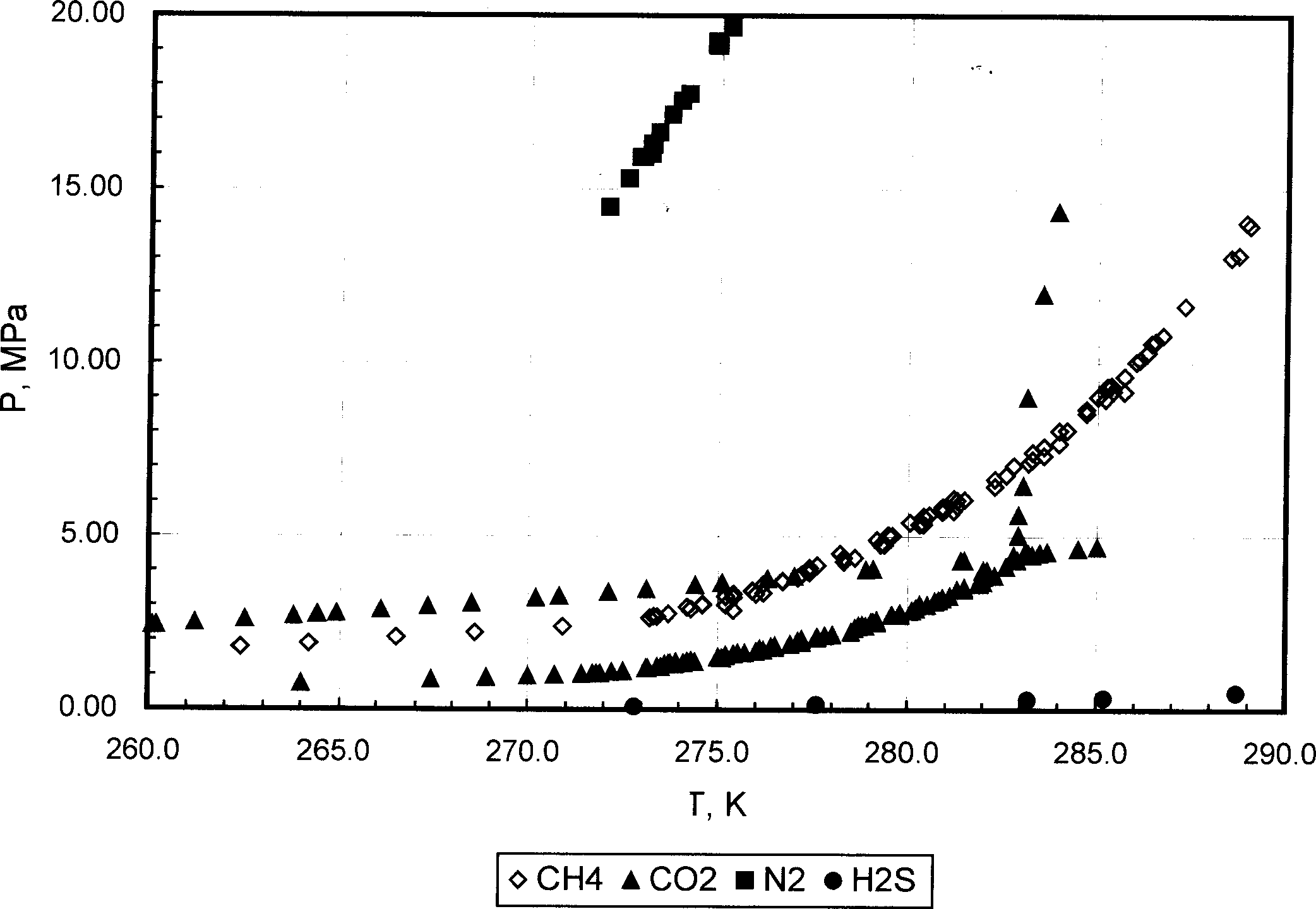

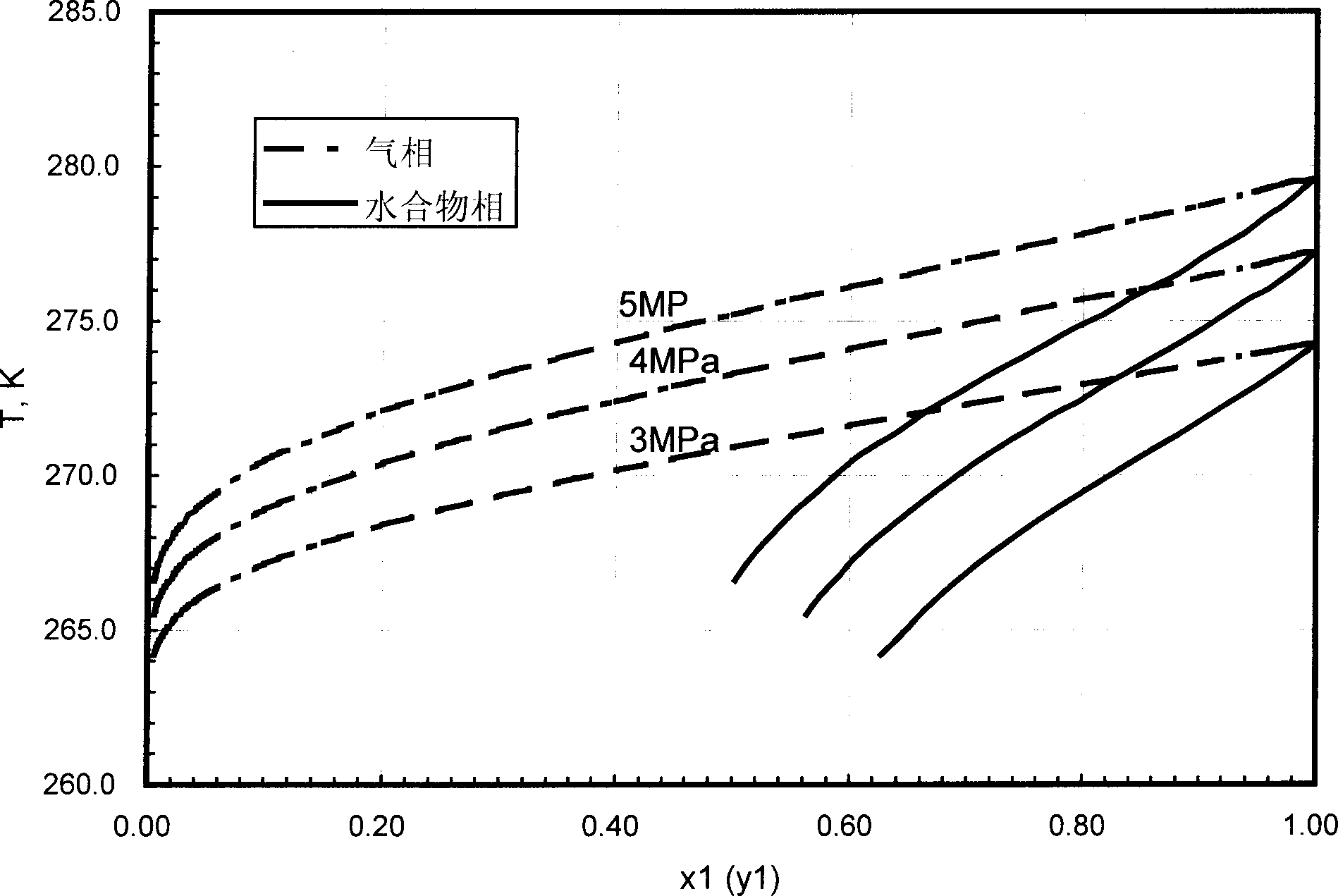

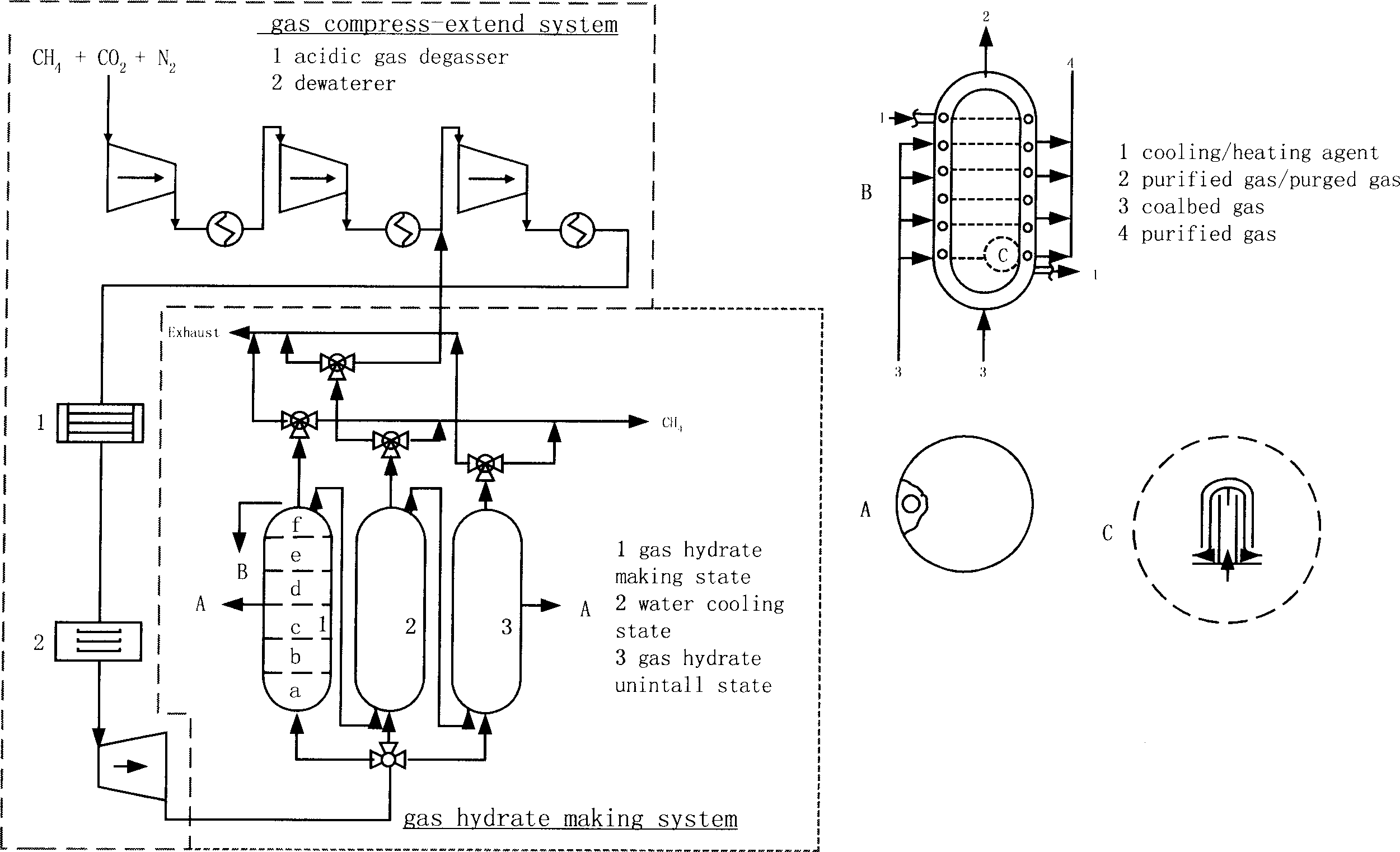

The present invention provides a method capable of utilizing hydrate to make concentration, storage of utilizing hydrate to make concentration, storage and transportation of coal-bed gas and its equipment. Said method is characterized by that it utilizes the difference of distribution coefficient of methane (CH4) and other component in the coal-bed gas in gas phase and hydrate phase, and utilizes the control of generation condition of hydrate to make the methane (CH4) in coal-bed gas be concentrated in hydrate phase, then the generated pasty or solid hydrate can be directly used for storage and transportation of coal-bed gas, also can be decomposed, then it adopts the form of compressed gas to make storage and transportion.

Description

technical field [0001] The invention proposes a method and device for enriching, storing and transporting coalbed methane by utilizing hydrate. technical background [0002] Coalbed methane is an unconventional natural gas that is mainly in the state of adsorption, generated and stored in coal-measure strata, and its composition is basically the same as that of conventional natural gas (mainly composed of CH 4 , also contains N 2 , CO 2 CBM can be transported and mixed with conventional natural gas, and can be used as high-quality energy and chemical raw materials equal to conventional natural gas. According to the latest evaluation, my country's onshore coalbed methane resources buried below 2,000 meters are 31.46 trillion cubic meters, equivalent to 45 billion tons of standard coal or 31 billion tons of oil. The development and utilization of this high-quality clean energy can optimize my country's energy structure to a certain extent, improve coal mine safety productio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F17C5/00F17C11/00C10L3/00

Inventor 赵月红许志宏温浩何险峰王卫华

Owner INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com