A natural food emulsifier made from protein-polysaccharide covalent polymer and preparation method thereof

A natural food and protein technology, applied in food preparation, food science, application, etc., can solve the problems of poor compatibility, high molecular weight of polysaccharides, high product cost, etc., achieve good emulsification performance, wide application range, and small equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

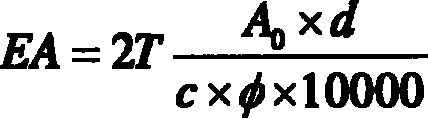

Method used

Image

Examples

Embodiment 1

[0015] Soybean protein isolate was dispersed in water at a mass concentration of 6%, heat-treated at 90°C for 15 minutes, cooled to room temperature, maltodextrin solution was added to make the mass concentration 12%, fully stirred and dissolved, and then spray-dried to form a mixed powder. Put the mixed powder in a closed incubator with saturated KBr solution (equivalent to a relative humidity of 79%), keep it at a constant temperature of 60°C for 7 days, and dry it in vacuum at 50°C for 2 hours to obtain the product.

Embodiment 2

[0017] Disperse soybean protein isolate in water at a mass concentration of 4%, heat-treat at 90°C for 15 minutes, cool to room temperature, add guar gum hydrochloric acid hydrolyzate to make the mass concentration 4%, fully stir and dissolve, then spray-dry to form a mixed powder body. Put the mixed powder in a closed incubator with saturated KBr solution (corresponding to a relative humidity of 79%), keep it at a constant temperature of 60°C for 10 days, and dry it in vacuum at 50°C for 2 hours to obtain the product.

Embodiment 3

[0019] Disperse soybean protein isolate protein in water at a mass concentration of 6%, heat it to 90°C, keep it warm for 20 minutes, then cool it to 50°C, add papain to make its mass concentration 0.1%, and the degree of hydrolysis to 2%, then heat it at 90°C °C water bath for 15 minutes to inactivate the protease. Then cool to room temperature to prepare protease hydrolyzate.

[0020] Make guar gum into a dispersion at a mass concentration of 3%, heat the dispersion to 90°C, and keep stirring to dissolve the polysaccharide molecules into a uniform colloidal solution, then add 6mol / L concentrated hydrochloric acid after cooling to room temperature Adjust the pH of the solution to 2.0, then raise the temperature of the polysaccharide solution to 90°C, heat it for 60 minutes and cool it to room temperature, and adjust the pH to 7.0 with 2mol / L NaOH. Polysaccharide molecules with a molecular weight cut-off of not less than 2,000 are cut off by an ultrafiltration membrane.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com