Automobile powered lifting device

A lifting device, car technology, applied in the direction of lifting device, lifting frame, etc., can solve the problem of single function, etc., and achieve the effect of low cost, easy manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

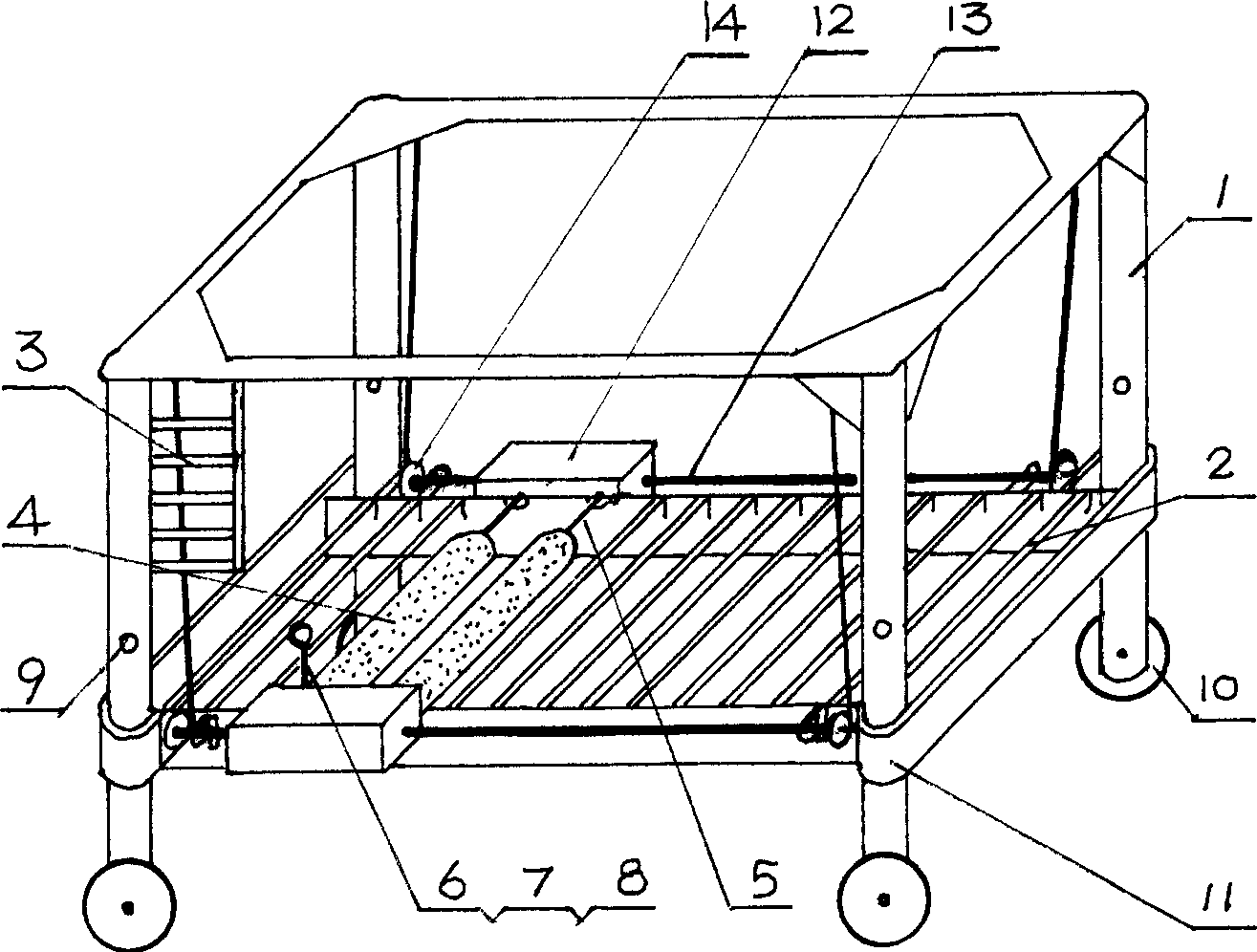

[0012] The car automatic power lifting device is mainly composed of a supporting frame 1, a parking platform 2, a gearbox 12, a lifting member composed of an output shaft 13 and a lifter 14, and a friction roller 4. The friction roller 4 passes through the driving shaft 5 and the gearbox 12. connect.

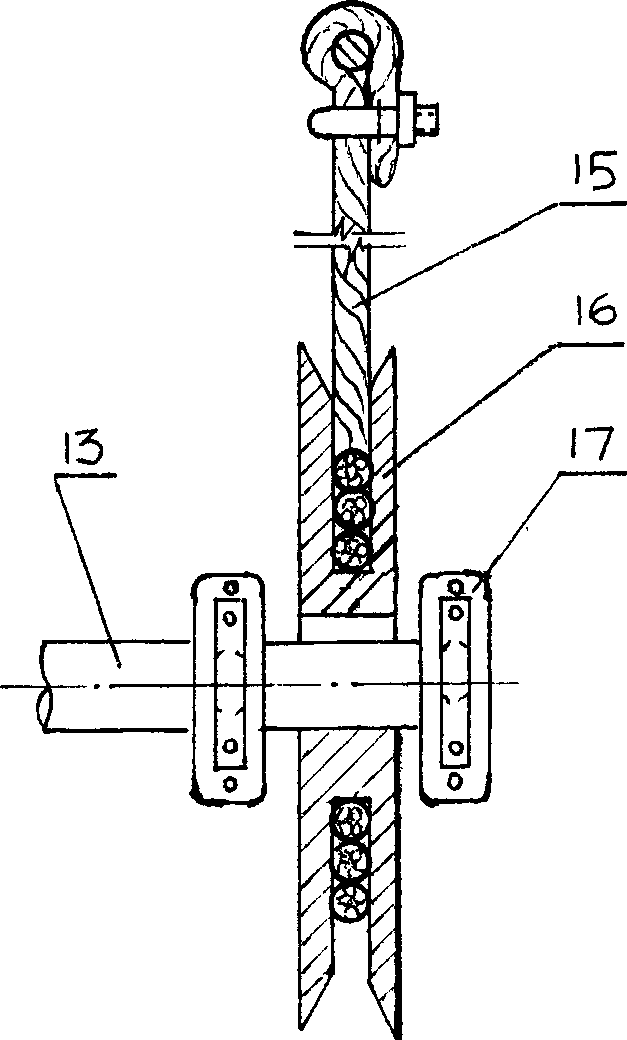

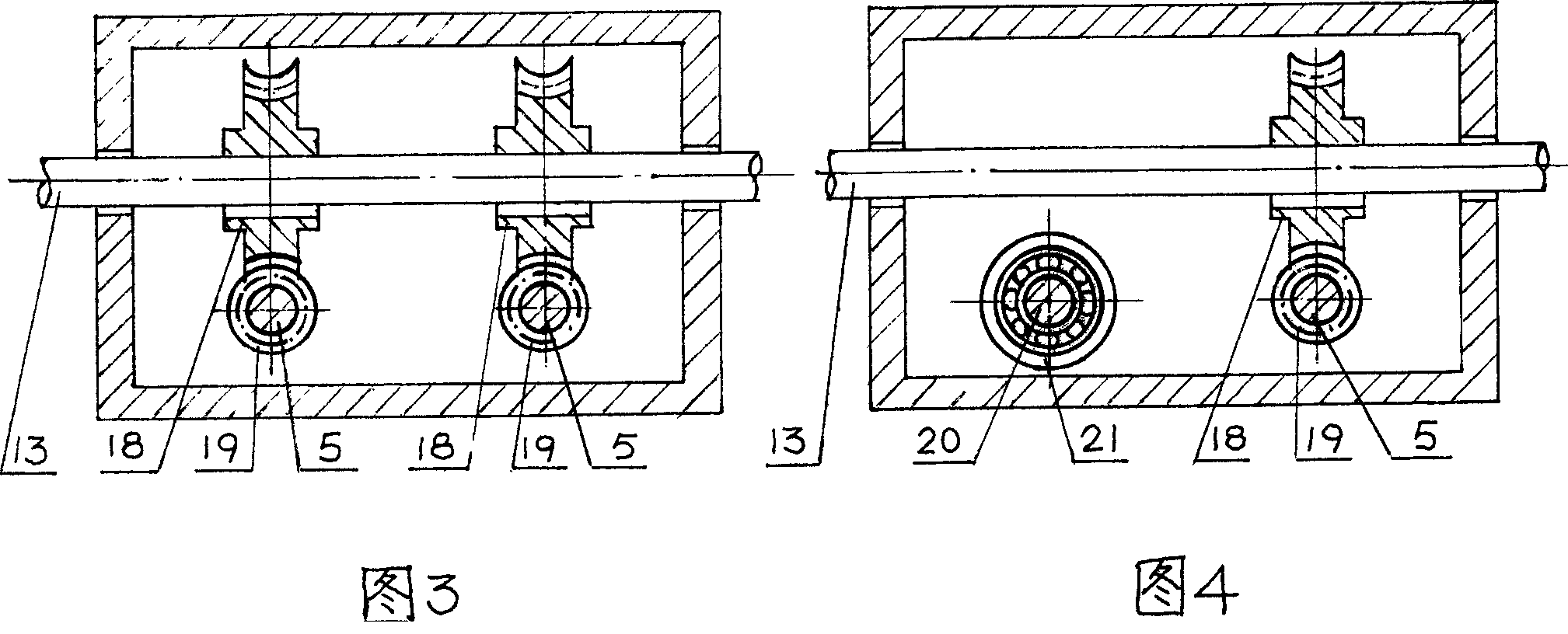

[0013] The working process characteristics of the present invention: (1), the car drives on the parking platform 2 that is in the low limit, the driving wheel presses and rotates the friction roller 4, and the worm screw 19 in the gearbox 12 is driven by the drive shaft 5 to drive the worm gear 18 to change speed Rotate, then by output shaft 13, be supported by bearing seat 17, drive rope reel 16 to wind up wire rope 15, reach the purpose that parking platform 2 rises. (2), when the friction roller 4 needs to change the direction of rotation, keep the unidirectionality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com