Integrally-cast mould-detachment-free concrete structure system and construction method thereof

A concrete structure and integral pouring technology, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of difficult precise positioning of steel bars and formwork, difficult guarantee of engineering quality, poor construction accuracy and overall rigidity, and achieve convenient construction Fast, high construction precision, and the effect of preventing leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

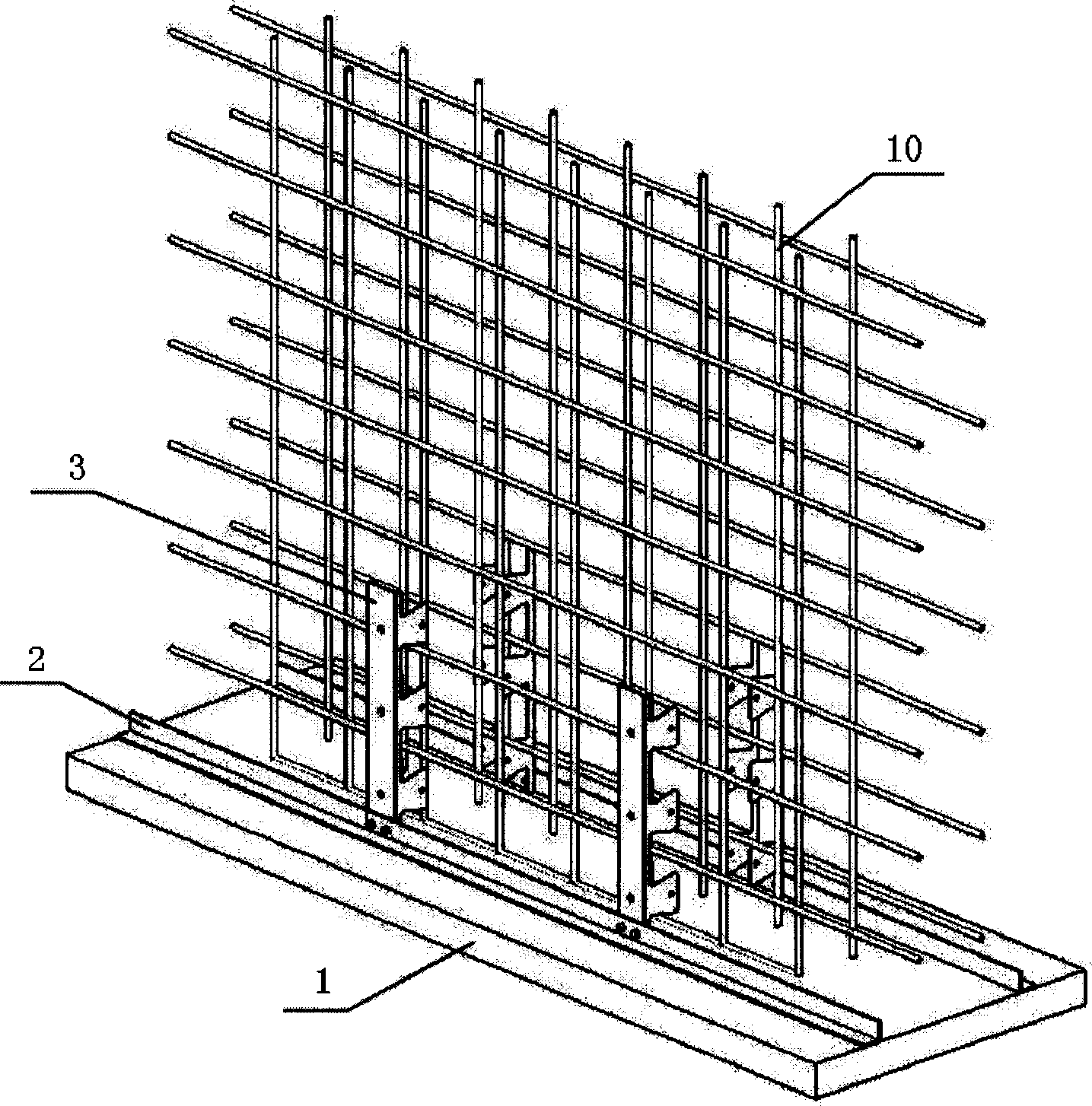

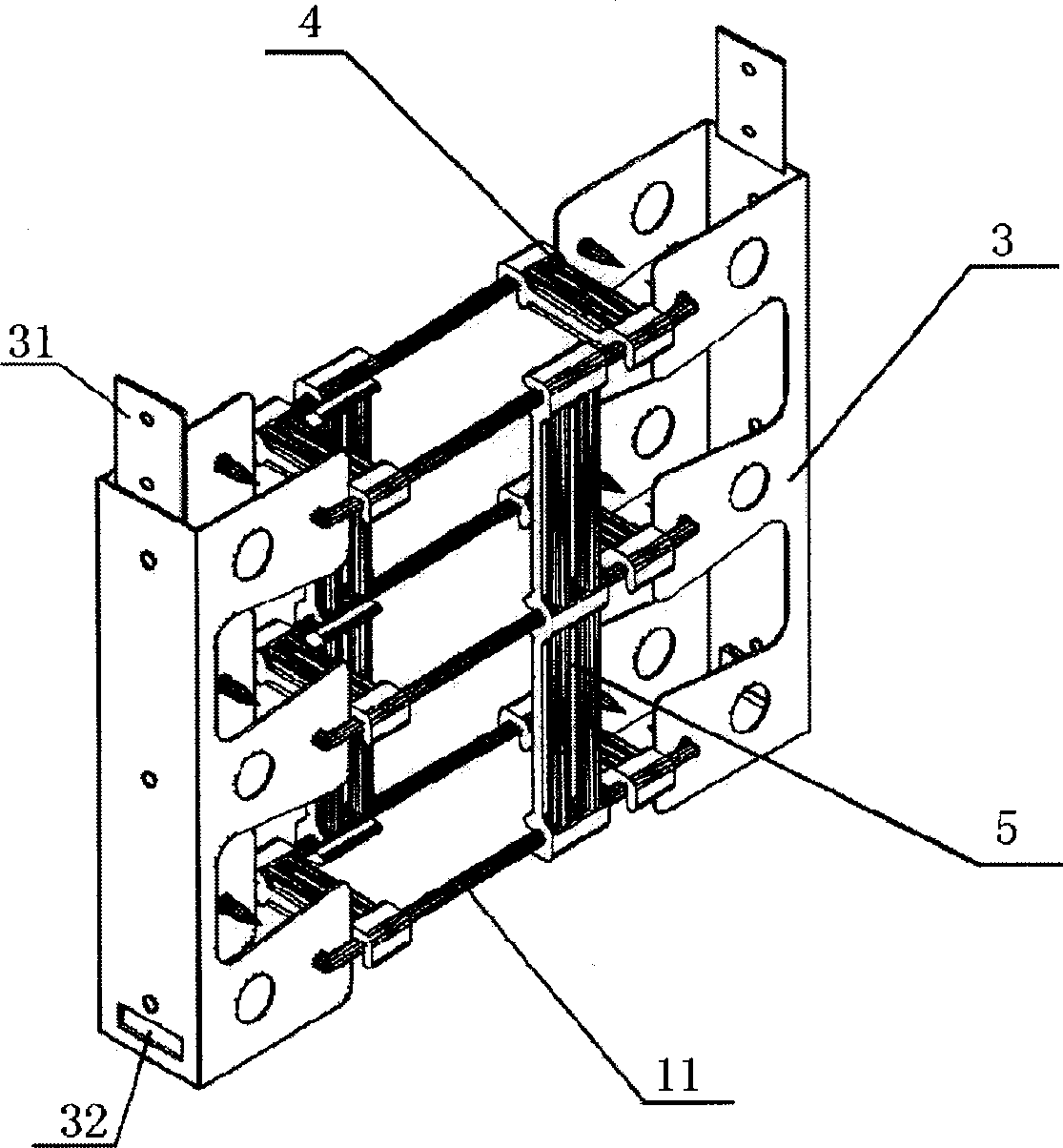

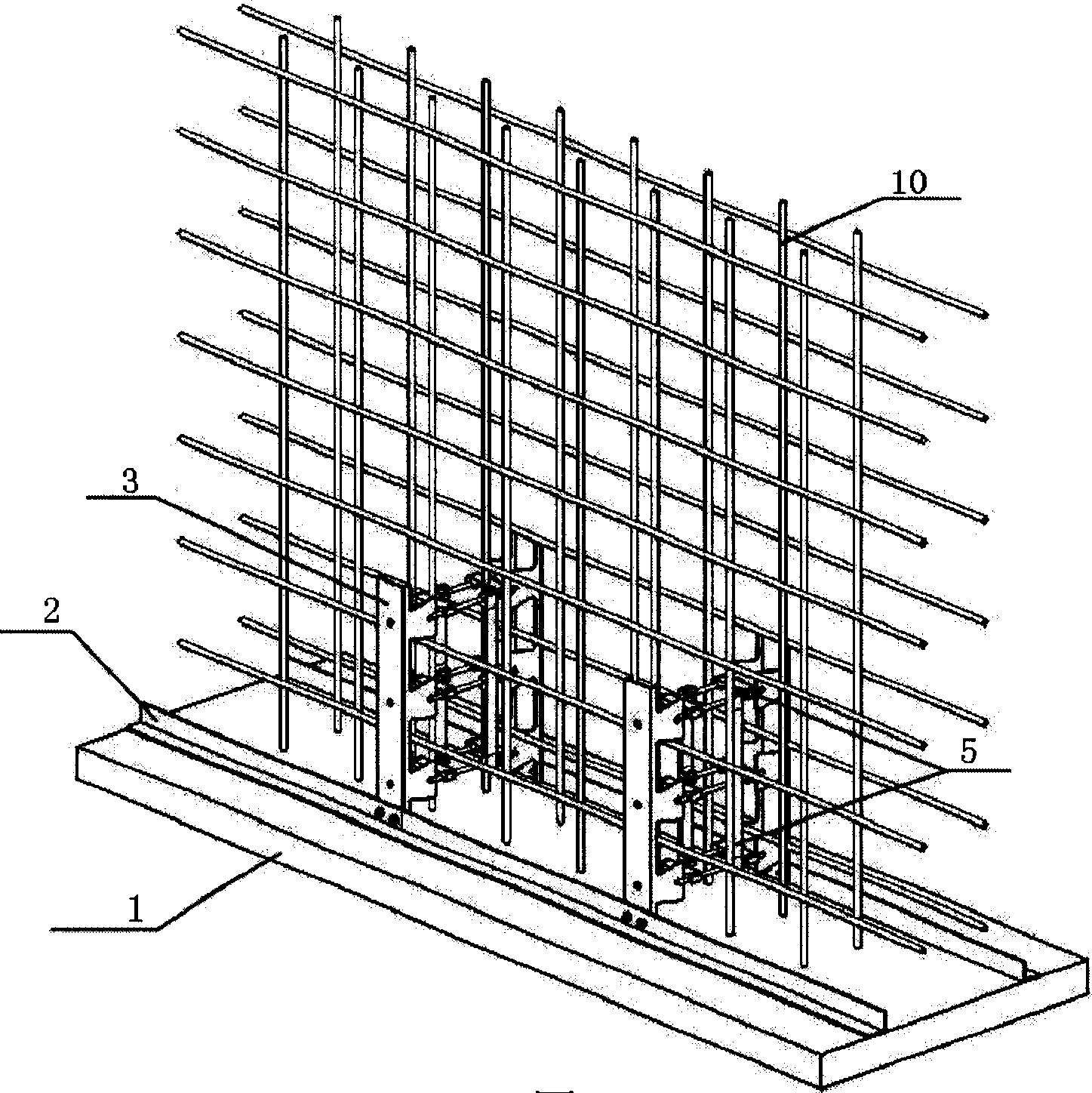

[0036] see Figure 1-10 , this integral pouring formwork-free concrete structure system consists of structural steel bars 10 pre-embedded on the foundation floor 1, non-demolition formwork on the periphery of the concrete pouring space, and concrete 12 poured into one body, including the structure pre-embedded on the foundation floor 1 Reinforcement bars 10 and the non-dismantling formwork on the periphery of the concrete pouring space, two positioning clips 2 spaced at the same width as the wall are horizontally fixed on both sides of the structural reinforcement 10 on the foundation floor 1, and the above positioning clips 2 can be angle steel or channel steel . The two positioning clips are fixedly connected with a group of steel sheet skeletons 3 that are upright at intervals and pulled oppositely, and the two outer sides of the steel sheet skeleton are connected by rivets 6 to the formwork-free liners 8, and the above-mentioned formwork-free liners 8 can be Plastic board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com