Power factor corrector

A power factor correction and coil technology, applied in the direction of output power conversion devices, transformers, inductors, etc., can solve the problems of raw material waste, magnetic line interference, increase raw material cost, etc., to reduce noise and low-frequency continuous wave interference, improve heat dissipation Efficiency, the effect of reducing the magnetic leakage phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

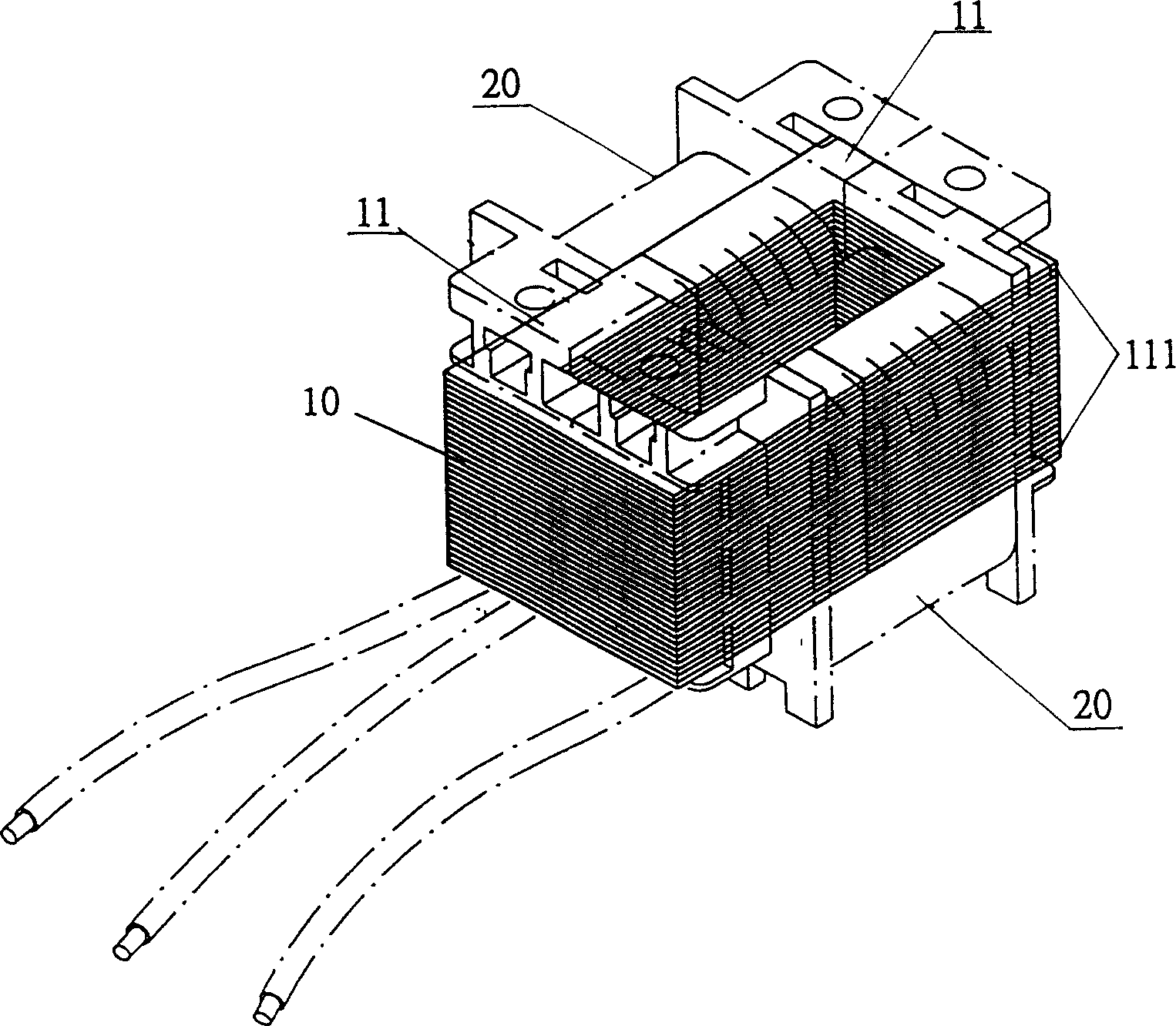

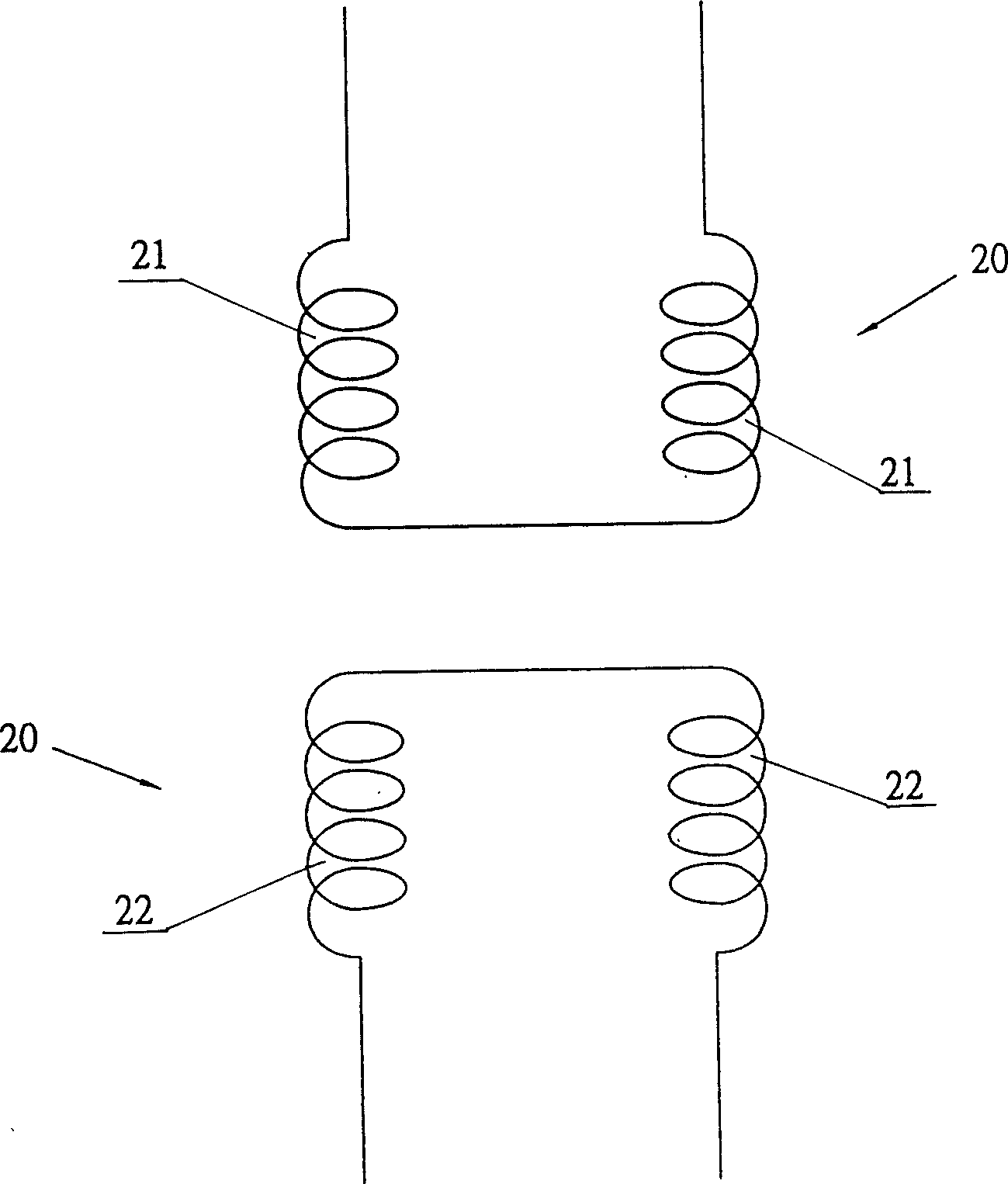

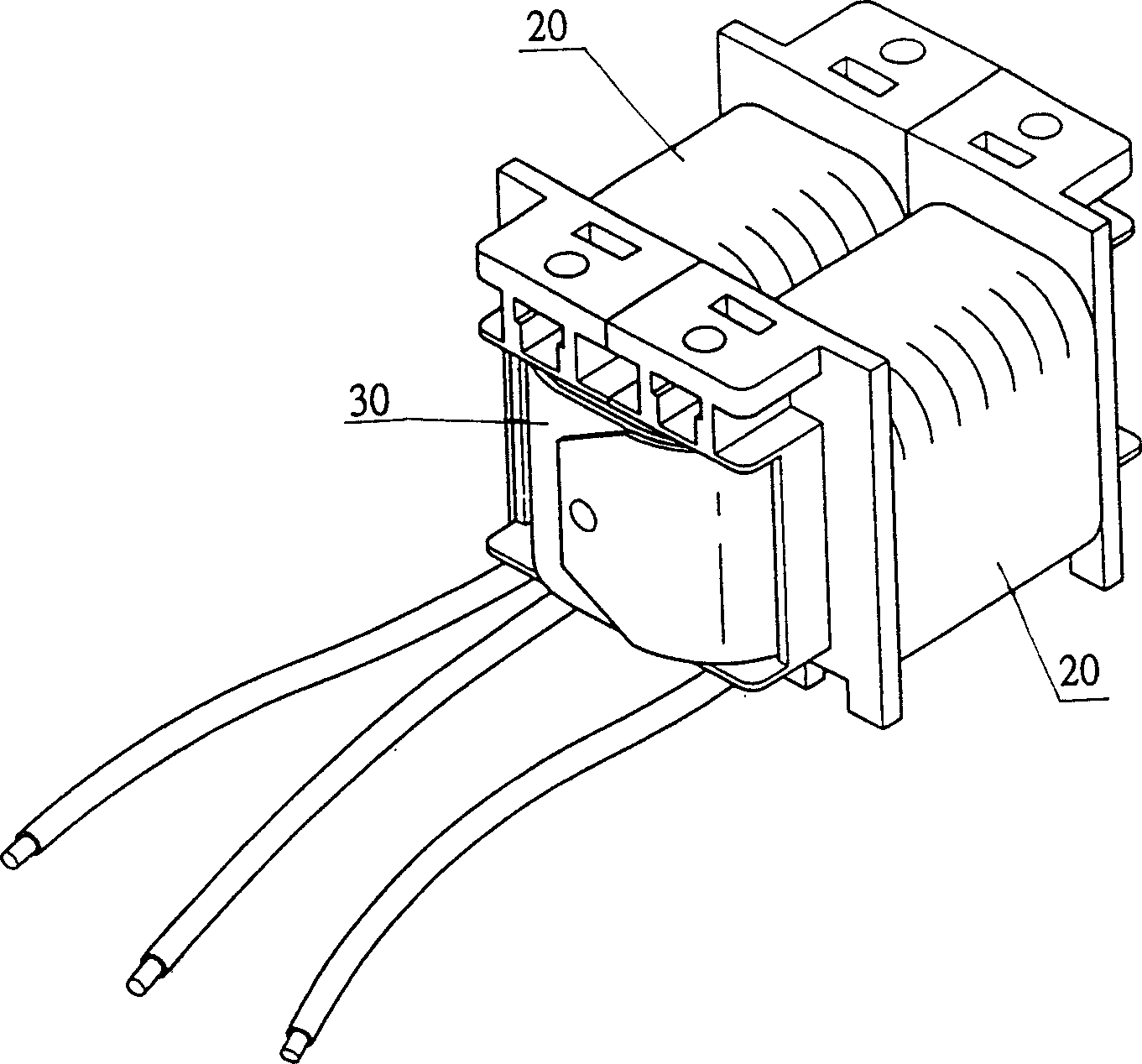

[0018] see image 3 , Figure 4 As shown in Fig. 5, a power factor corrector, the iron core enclosed in the coil package 20 is a coiled iron core 30, and the entire iron core 30 is basically wound with a steel strip 311 to form an inner ring type Egg-shaped body 31, the egg-shaped body 31 is cut into two symmetrical combined blocks 32, and the two combined blocks 32 are inserted into the coil 20 structure of the power factor corrector in a docking manner to form a complete The iron core 30 is constructed and assembled with the coil package 20 to form a power factor corrector.

[0019] Among them, the egg-shaped body 31 used to form the iron core 30 is formed by winding silicon steel strips, so the waste of materials can be greatly reduced, and the cost can be effectively reduced. The coil body formed by the package 20 is relatively easy to assemble, which can effectively reduce the generation of defective products, and the generated magnetic crystals have a non-directional s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com