Printing method for nail care implement

A printing method and technology of utensils, applied in the direction of manicure or pedicure tools, printing, copying/marking methods, etc., can solve the problems such as the reduction of grinding function, and achieve the effects of preventing precipitation, inhibiting decolorization, and solving the reduction of grinding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

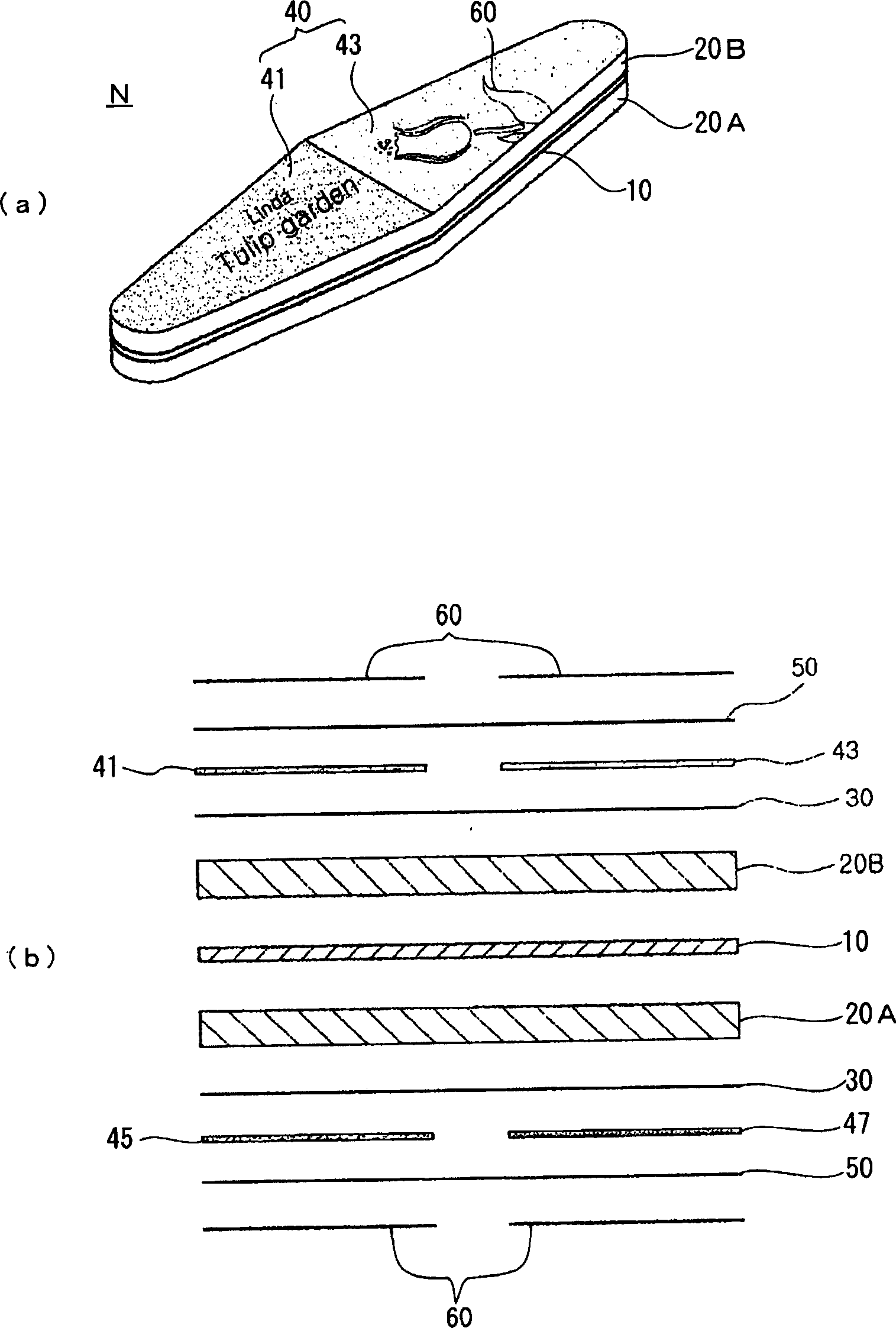

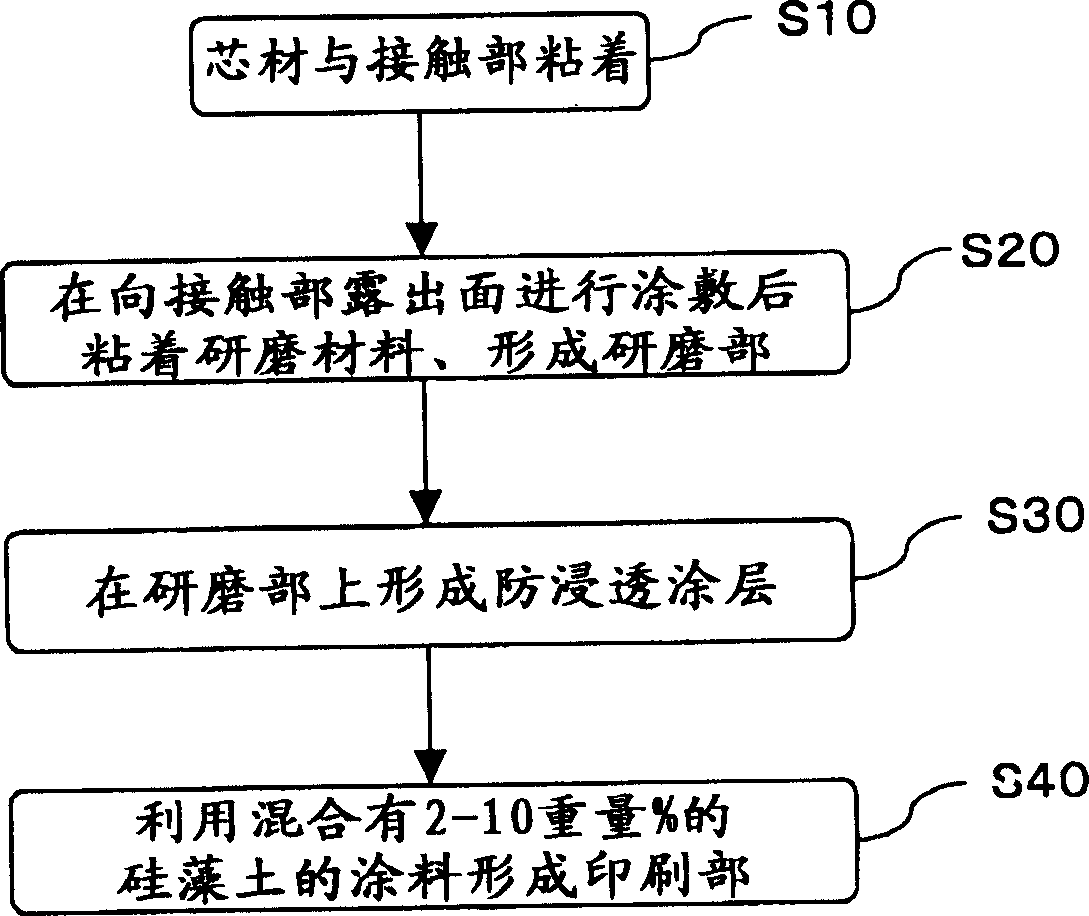

[0018] Below, with regard to the embodiment of the present invention, refer to the appended Figure 1 The description is provided for understanding the present invention. figure 1 It is the combined perspective view (a) and disassembled cross-sectional view (b) of the hand and foot nail trimming appliance printed according to the printing method of the present invention. figure 1 (b) The thickness of each layer is exaggerated for the sake of understanding.

[0019] First, in figure 1 (a) and figure 1 (b) and figure 2 Among them, the hand and foot nail trimming device (N) is made of polycarbonate, polyethylene (PE), polypropylene (PP) or acetal such synthetic resin plate, etc., on both sides of the core material (10) with certain flexibility , the contact portion (20A) (20B) (S10, referring to figure 2 ).

[0020] Preferably, the contact part is only adhered to one side of the core material (10), and is made of materials such as foamed polyurethane or polystyrene, and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com