High-voltage gas discharge lamp with assistant reflection device

A high-pressure gas and reflector technology, which is applied to gas discharge lamps, discharge lamps, components of lighting devices, etc., can solve the problems of deterioration of the reflective coating layer, focus displacement, falling off, etc., to maintain brightness, maintain life, and improve brightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

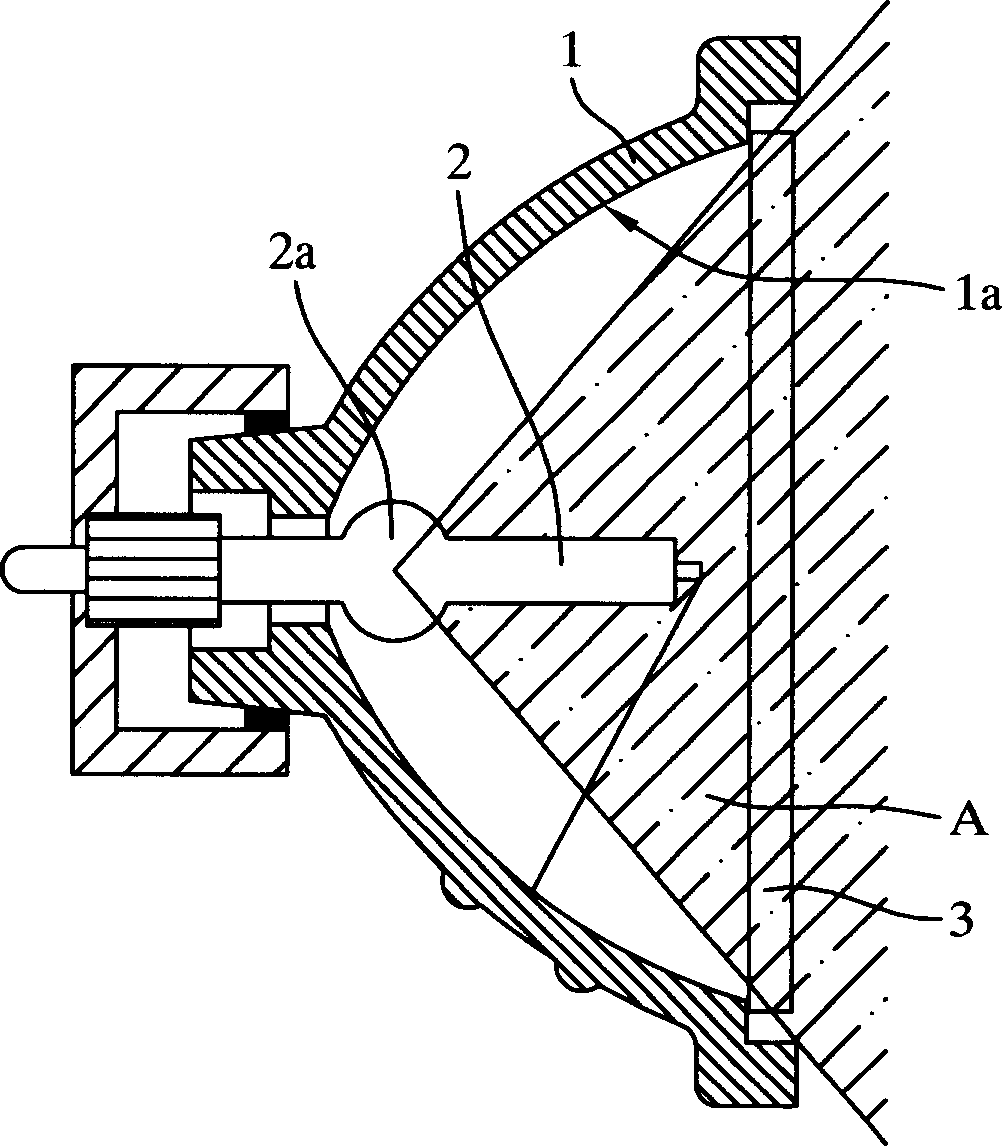

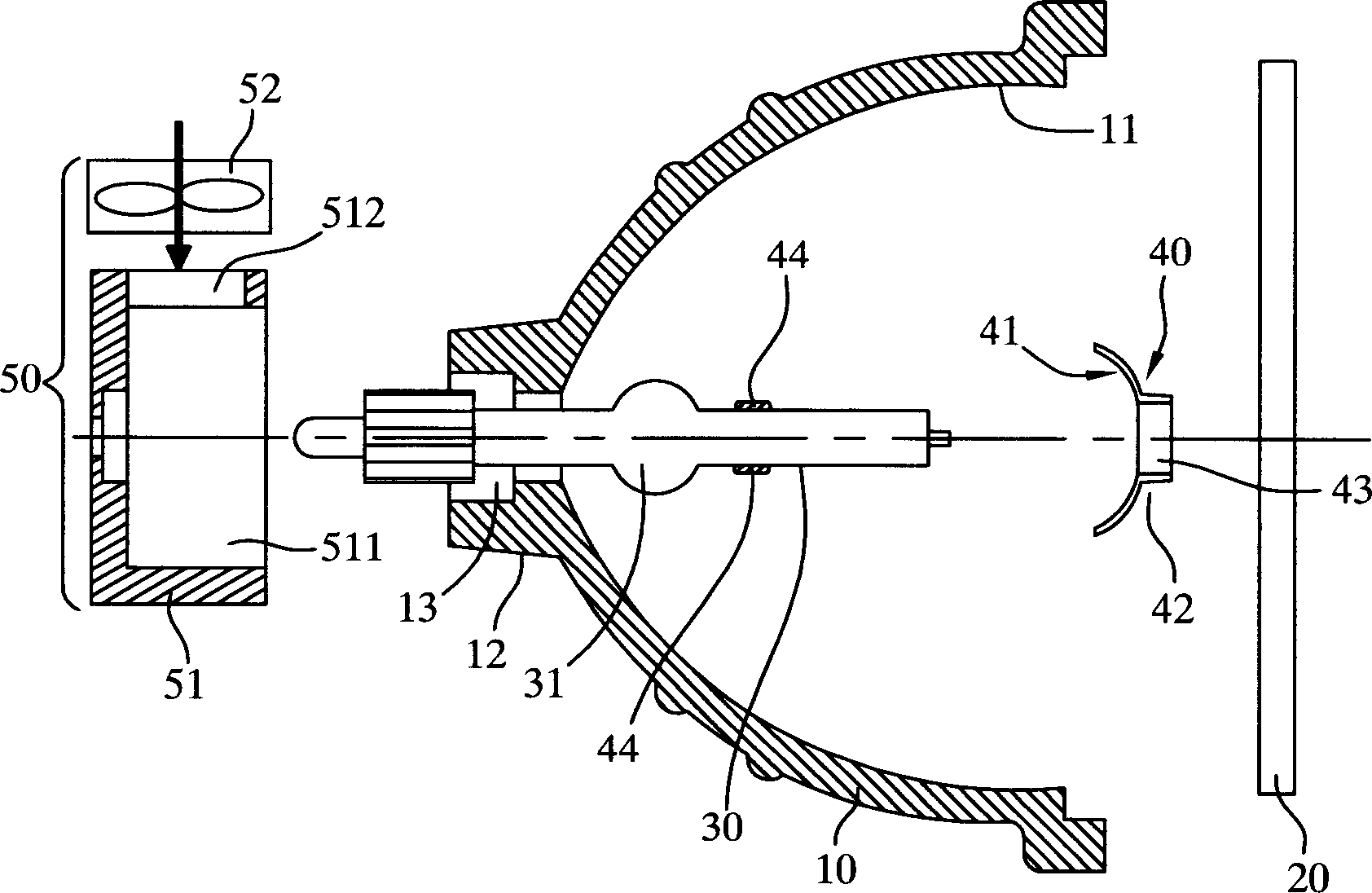

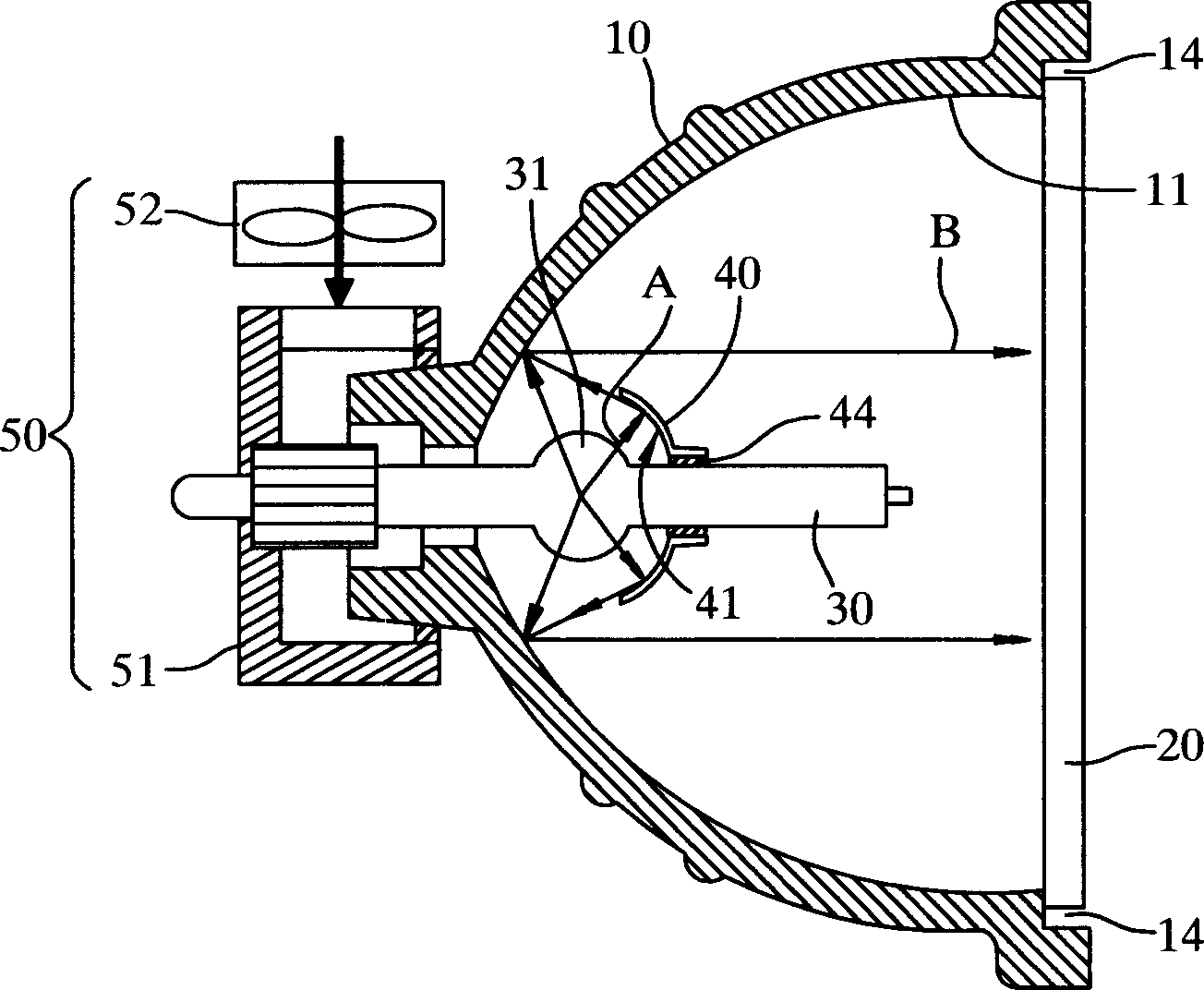

[0051] see figure 2 and image 3 As shown, a high-pressure gas discharge lamp with an auxiliary reflection device provided by a preferred embodiment of the present invention can reflect the ineffective light generated by the discharge lamp tube, change its projection path, and form effective light to improve Lighting effects of high pressure gas discharge lamps.

[0052] The high-pressure gas discharge lamp with an auxiliary reflector of the present invention includes: a reflector 10 , a front lamp cover glass 20 , a discharge lamp 30 , an auxiliary reflector 40 and a cooling device 50 .

[0053] The inner surface of the reflector 10 forms a main reflective surface 11, and the main reflective surface 11 is usually in the shape of a paraboloid or an ellipse. On the outer surface of the reflector 10 , an outwardly protruding neck 12 (Neck) is formed corresponding to the position of the axis, and the central axis of the neck 12 has a through hole 13 . The headlight cover glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com