Nonwoven elastic fibrous webs and methods for making them

A fibrous web, elastic fiber technology, applied in fiber processing, textile and papermaking, fiber chemical characterization, etc., can solve problems such as unsatisfactory opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

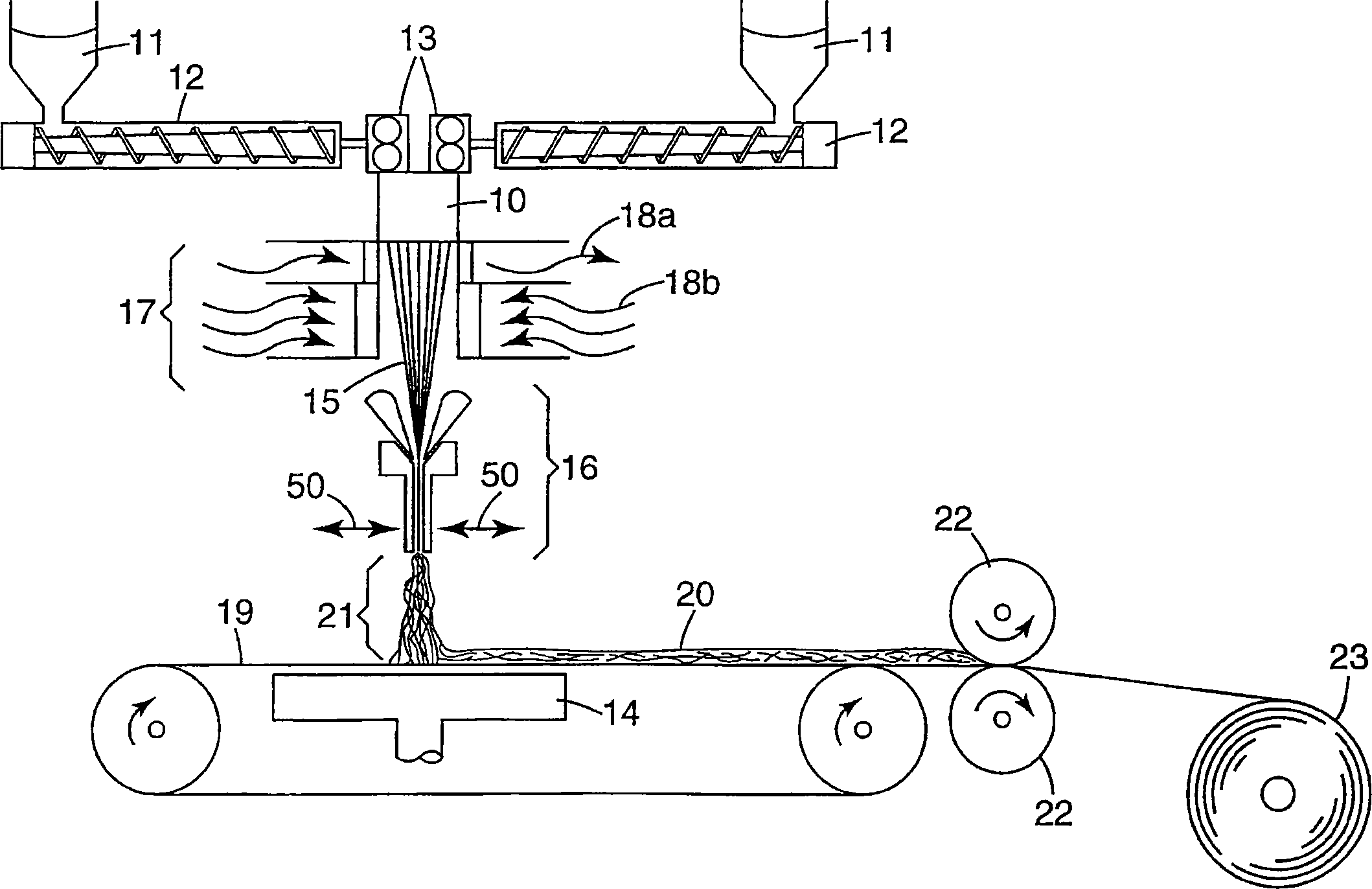

[0020] figure 1 An illustrative apparatus that can be used to prepare the nonwoven fibrous web of the present invention is shown. The fiber-forming material is fed to extrusion head 10 in this particular illustrative apparatus by introducing the fiber-forming material into feeder 11; melting the material in extruder 12; The molten material is pumped into extrusion head 10 . Other fiber-forming materials, such as polymer solutions, may also be used, although solid polymer materials in pellets or other specific shapes are most commonly used and melt into a liquid in a pumpable state.

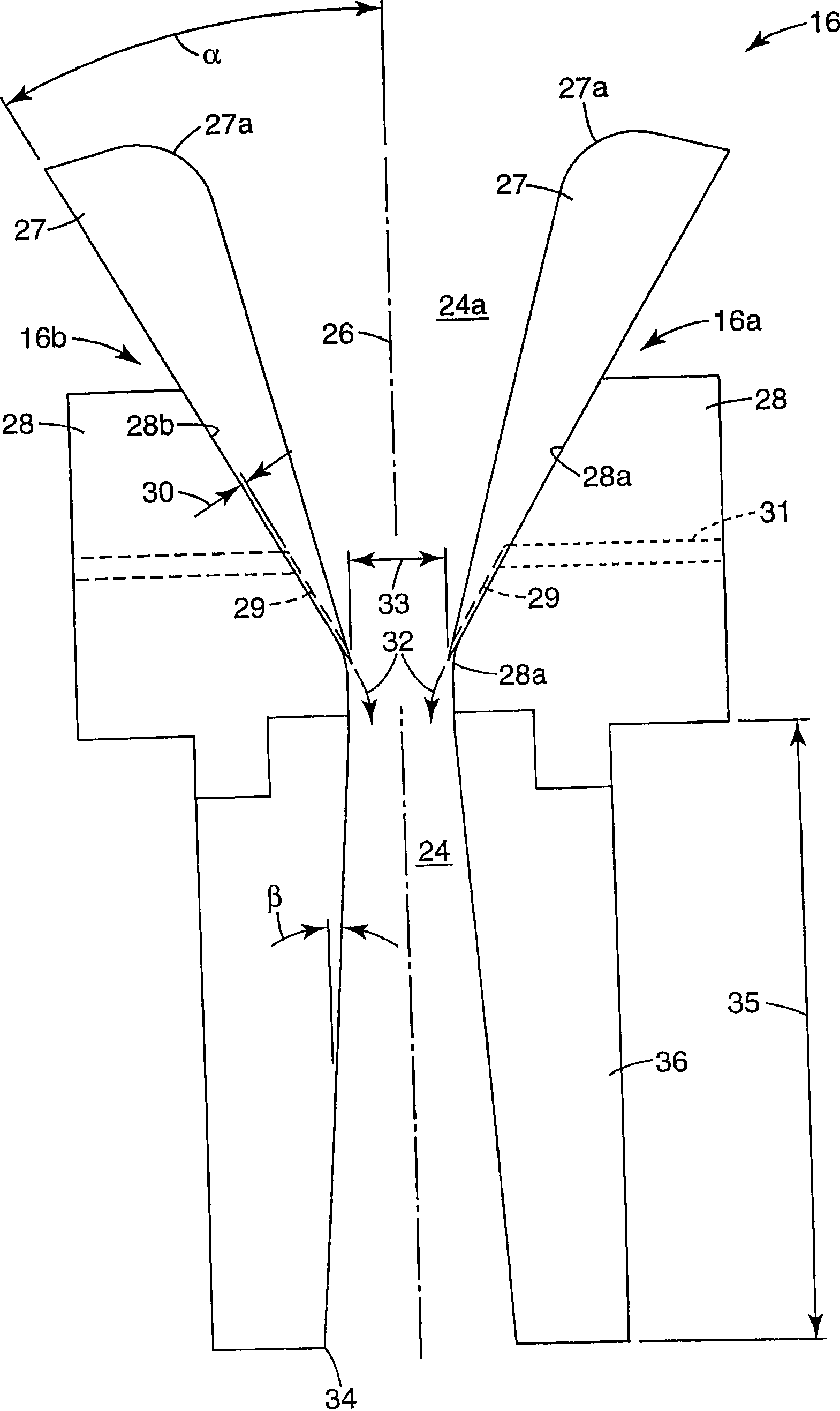

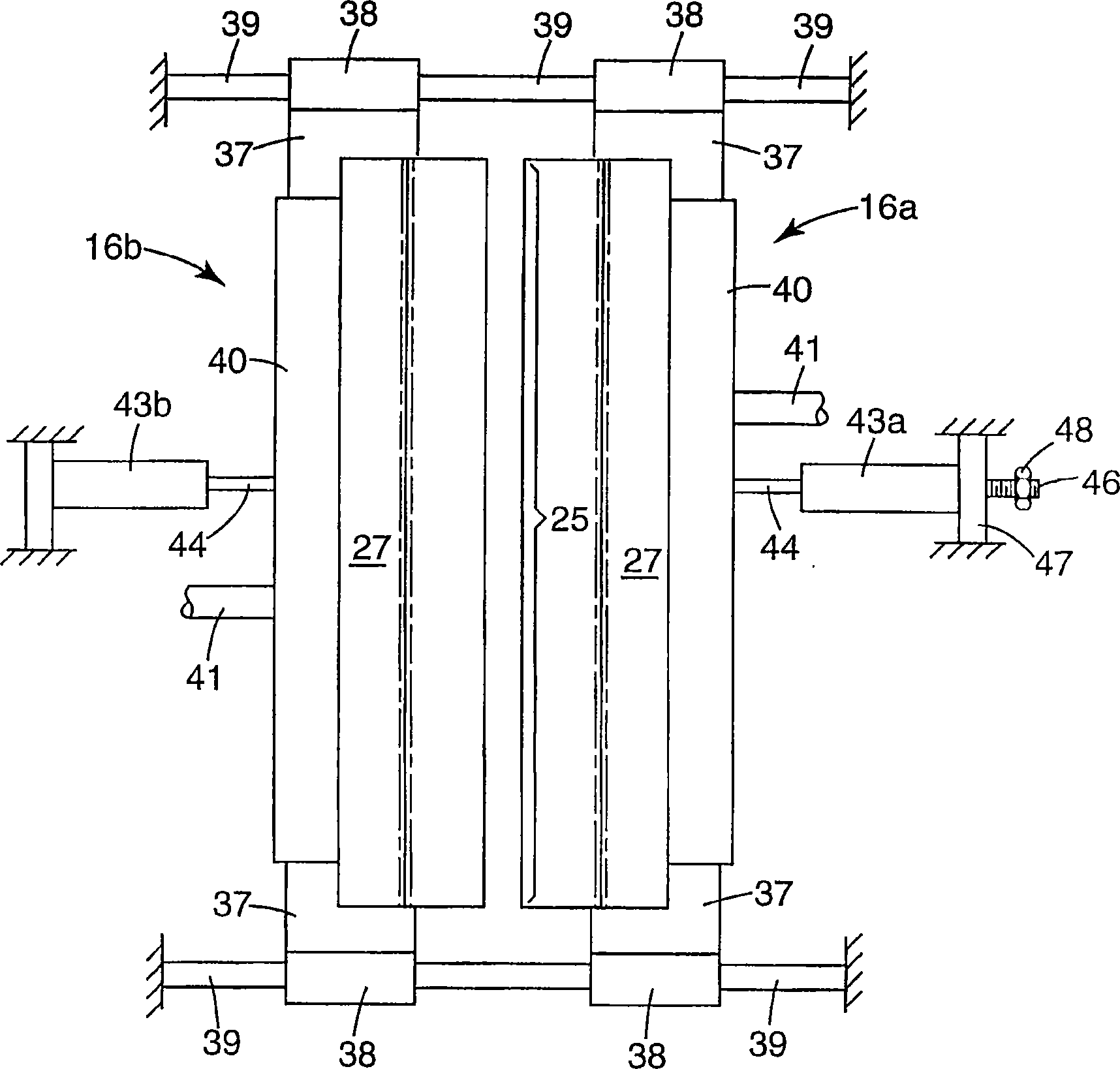

[0021] The extrusion head 10 may be a conventional spinneret or spinneret pack, typically comprising a plurality of orifices arranged in a regular pattern, for example in a linear array. Filament-forming liquid filaments 15 are extruded from the extrusion head and conveyed into a treatment chamber or attenuator 16 . Typically, some cooling stream of air or other gas is provided to the extruded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com