Method for preparing epoxy resin composite material from circuit board reclaimed material

A technology of epoxy resin and composite materials, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of complicated preparation methods, high cost, and limited application range of conductive epoxy resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

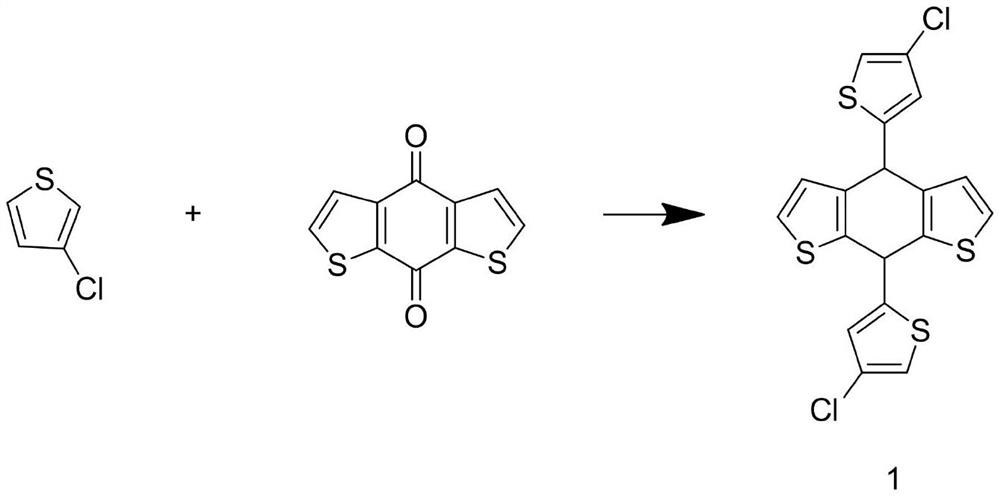

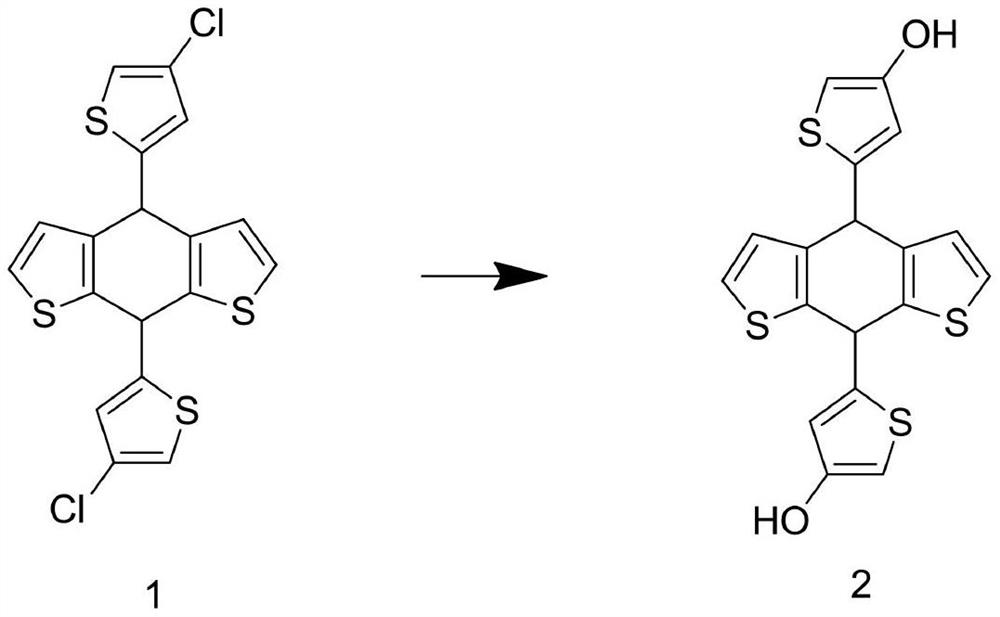

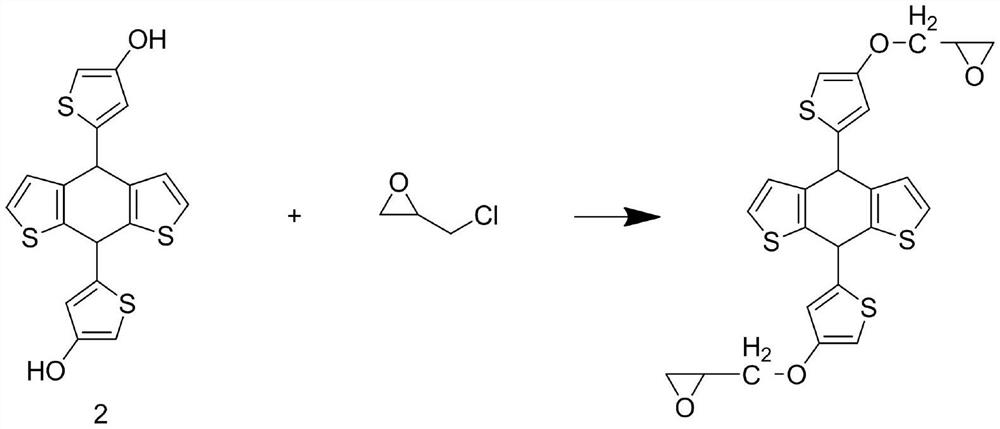

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing an epoxy resin composite material from recycled circuit board materials, wherein the epoxy resin composite material prepared from recycled circuit board materials includes the following raw materials in parts by weight:

[0033] 20 parts of circuit board recycling material, 30 parts of epoxy resin prepolymer, 10 parts of curing agent;

[0034] The epoxy resin composite material prepared from the circuit board reclaimed material is made by the following steps:

[0035] Step A1, breaking the recycled circuit board material into small pieces, putting it into a 10% sodium hydroxide solution by mass, boiling it, washing it twice with deionized water, drying it at 80°C for 3 hours, and soaking it in an acidic solution After 4 hours, the soaking solution was obtained, and then hydrometallurgy was carried out to obtain metal compound precipitation from the soaking solution;

[0036] Step A2, put the metal compound precipitation and sulfur powder prepared...

Embodiment 2

[0049] A method for preparing an epoxy resin composite material from recycled circuit board materials, wherein the epoxy resin composite material prepared from recycled circuit board materials includes the following raw materials in parts by weight:

[0050] 25 parts of recycled circuit board, 35 parts of epoxy resin prepolymer, 15 parts of curing agent;

[0051] The epoxy resin composite material prepared from the circuit board reclaimed material is made by the following steps:

[0052] Step A1, break the recycled circuit board material into small pieces, put it into a 10% sodium hydroxide solution by mass, boil it, wash it twice with deionized water, dry it at 85°C for 3 hours, and soak it in an acidic solution After 4 hours, the soaking solution was obtained, and then hydrometallurgy was carried out to obtain metal compound precipitation from the soaking solution;

[0053] Step A2, put the metal compound precipitate and sulfur powder prepared in step A1 into a flask, add D...

Embodiment 3

[0066] A method for preparing an epoxy resin composite material from recycled circuit board materials, wherein the epoxy resin composite material prepared from recycled circuit board materials includes the following raw materials in parts by weight:

[0067] 30 parts of circuit board recycling material, 40 parts of epoxy resin prepolymer, 20 parts of curing agent;

[0068] The epoxy resin composite material prepared from the circuit board reclaimed material is made by the following steps:

[0069] Step A1, break the recycled circuit board material into small pieces, boil it in a 10% sodium hydroxide solution, wash it three times with deionized water, dry it at 90°C for 4 hours, and soak it in an acidic solution After 5 hours, the soaking solution was obtained, and then hydrometallurgy was carried out to obtain metal compound precipitation from the soaking solution;

[0070] Step A2, put the metal compound precipitate and sulfur powder prepared in step A1 into a flask, add DMF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com