Process for preparing sodium antimony sulfide microwires and array thereof

A technology of antimony sulfide nano and micron wires, which is applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., and can solve the problems of inconvenient synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

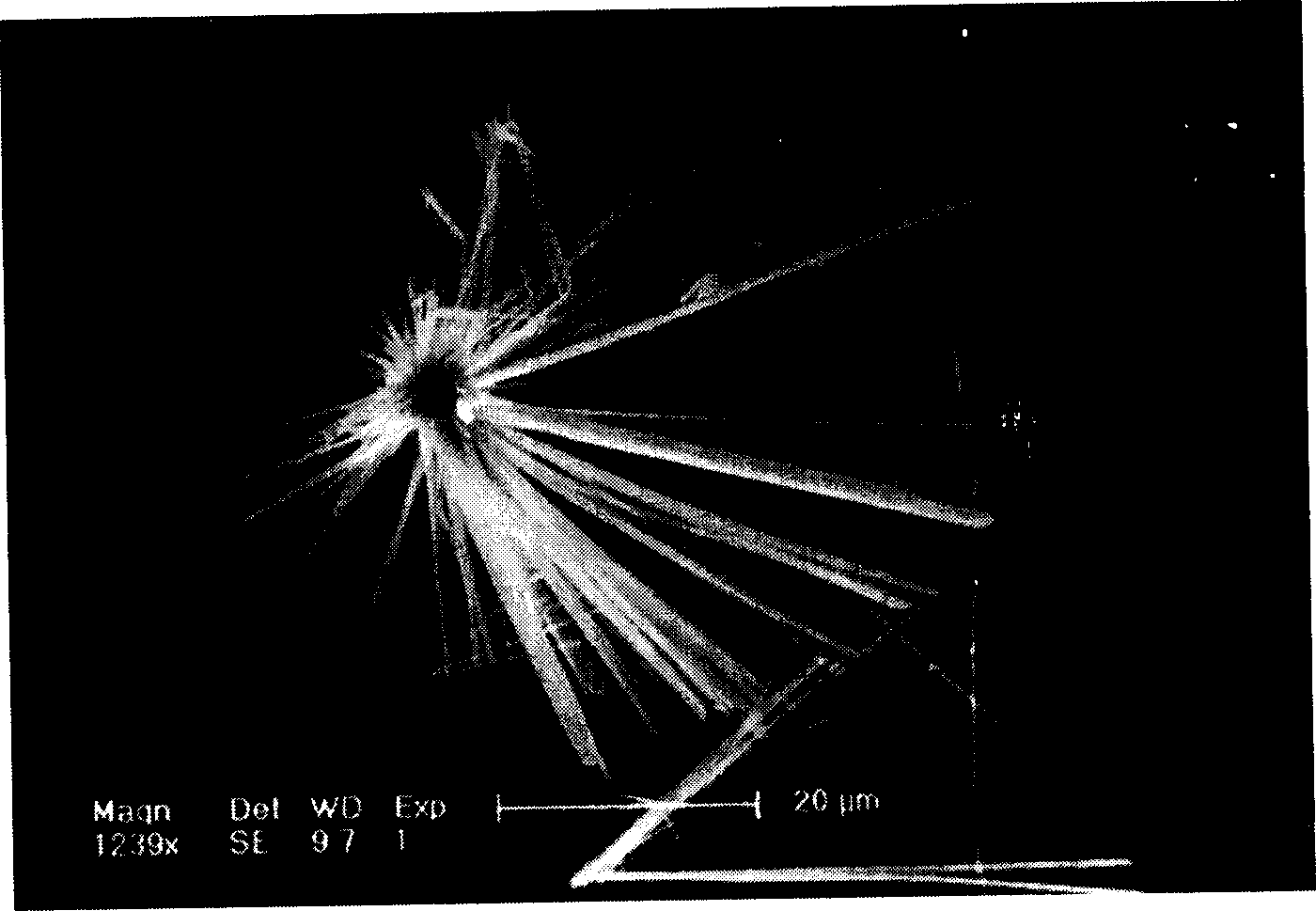

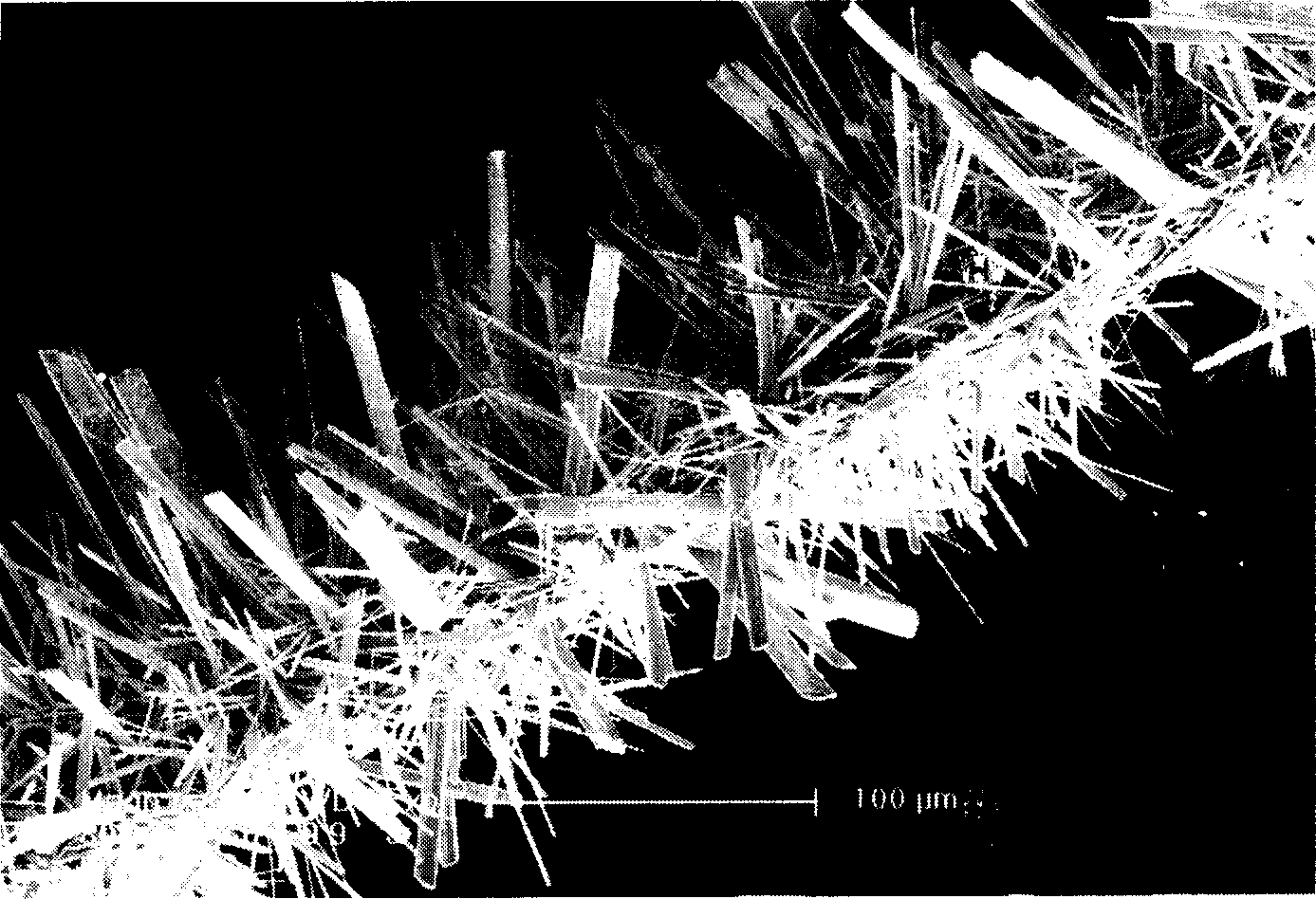

Embodiment 1

[0014] Weigh 200mg potassium antimony tartrate (0.6mmol), 200mg trisodium citrate dihydrate (0.68mmol), 50mg thiomalic acid (0.33mmol), dissolve them in 50ml secondary water successively under stirring, and put this mixed solution into In the polytetrafluoroethylene lining of a stainless steel autoclave with a capacity of 50ml, the lining containing the solution is sealed in a stainless steel autoclave, and heated at 200° C. for 24 hours to obtain antimony sulfide nano-micron wires.

Embodiment 2

[0016] Weigh 200mg of potassium antimony tartrate (0.6mmol), 200mg of trisodium citrate dihydrate (0.68mmol), and 9mg of thiomalic acid (0.06mmol), dissolve them in 50ml of secondary water successively under stirring, and put this mixed solution into In the polytetrafluoroethylene lining of a stainless steel autoclave with a capacity of 50ml, the lining containing the solution is sealed in a stainless steel autoclave, and heated at 140° C. for 24 hours to obtain antimony sulfide nano-micron wires.

Embodiment 3

[0018] Weigh 200mg of potassium antimony tartrate (0.6mmol), 200mg of trisodium citrate dihydrate (0.68mmol), and 540mg of thiomalic acid (3.6mmol), dissolve them in 50ml of secondary water successively under stirring, and put this mixed solution into In the polytetrafluoroethylene lining of a stainless steel autoclave with a capacity of 50ml, the lining containing the solution is sealed in a stainless steel autoclave, and heated at 240° C. for 3 hours to obtain antimony sulfide nano-micron wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com