High power pulse blood fluke cercaria killing method

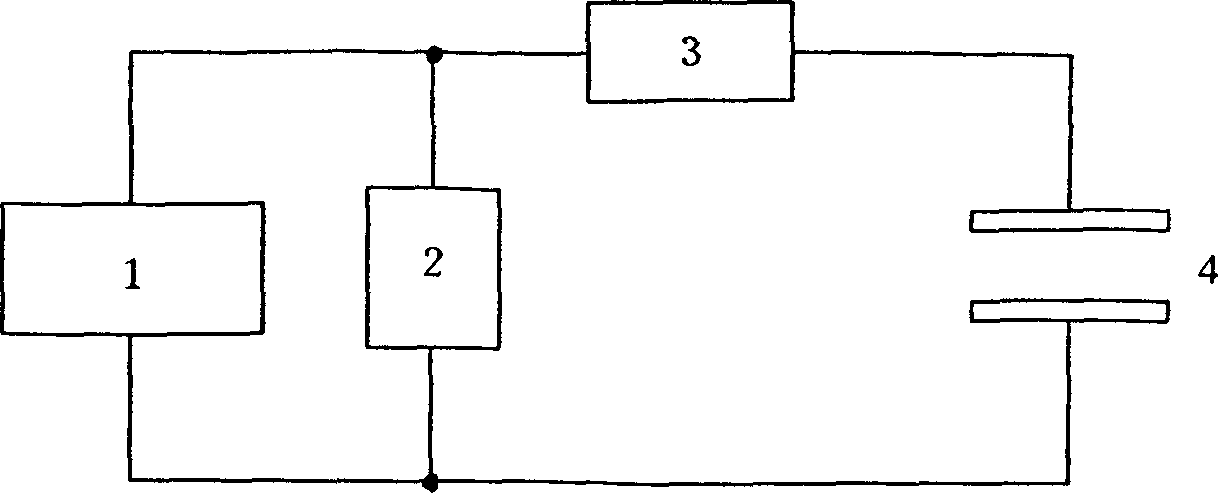

A high-power pulse and schistosomiasis technology, which is applied to devices for catching or killing insects, equipment for generating electric shocks, electrical components, etc., can solve problems such as not being able to be used on a large scale, poor killing effect, and environmental toxicity. To achieve the effect of solving the problem of drug resistance, a wide range of applications, and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

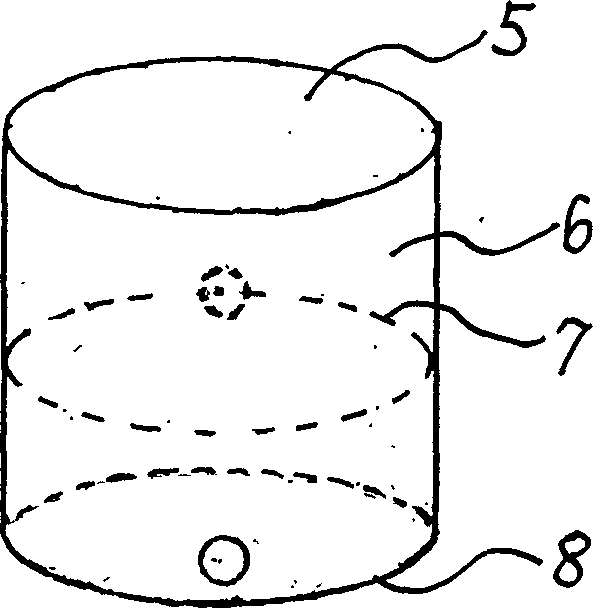

[0018] Embodiment one: to the processing of domestic water (belonging to still waters), as figure 2 shown. The processing chamber is a cylindrical shape made of insulating material, with a height of 0.5 meters. The diameter of the top 5 and the bottom 8 is 0.5 meters. Both the top 5 and the bottom 8 are made of a sealed plate. Part 6 is sealed and connected with the whole plate, so that the whole processing chamber is kept sealed. A water inlet is opened at 0.4 meters away from the bottom 8 on the side part 6 of the treatment chamber, and a drainage hole is opened at 0.05 meters away from the bottom 8 . The high-voltage discharge electrode adopts parallel plate electrodes, the top electrode is installed on the inner side of the top 5 of the processing chamber, and the bottom electrode is installed on the inner side of the bottom 8 of the processing chamber. The water to be treated is injected into the treatment chamber through the water inlet hole. The water level 7 in the ...

Embodiment 2

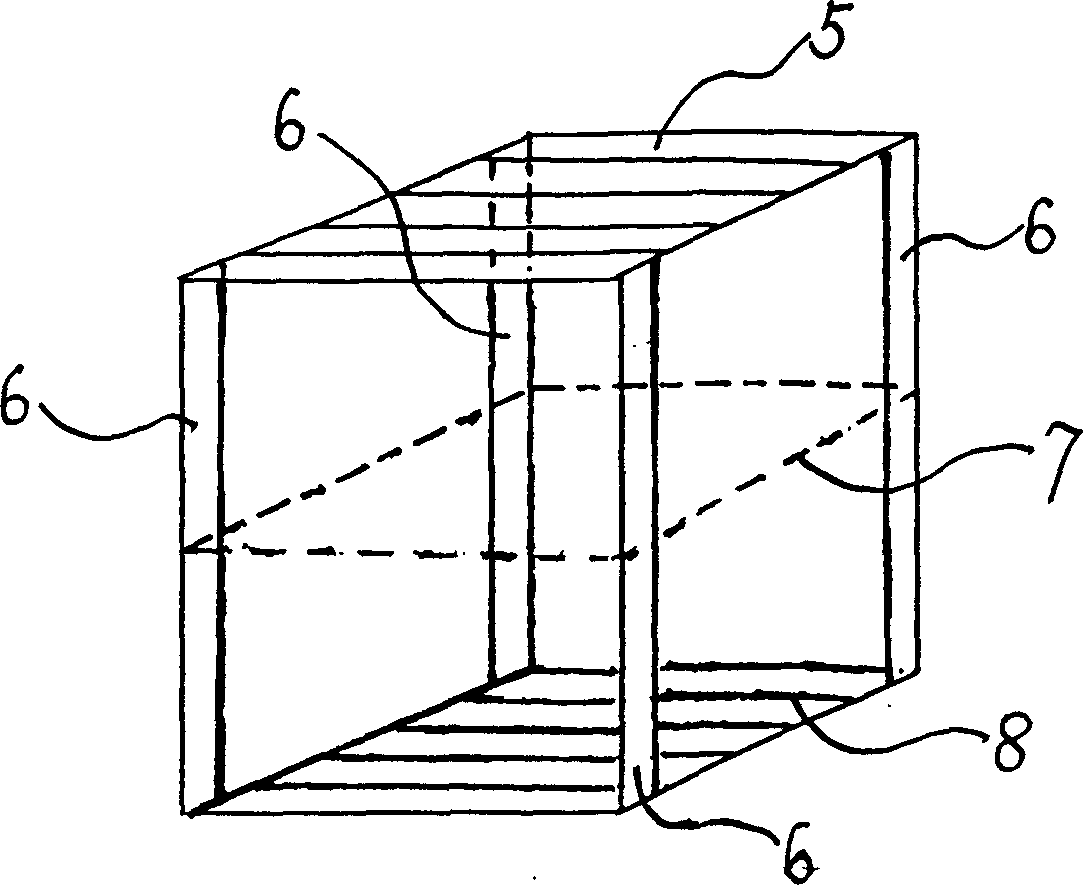

[0019] Embodiment two: to the processing of open waters, as image 3 shown. The processing chamber is a rectangular parallelepiped made of insulating material, 0.5 meters high, 0.3 meters wide, and 0.4 meters long. The top 5 and bottom 8 are made into transparent grids. 6 Use four support rods to connect at intervals to maintain the transparency of the top, bottom and side of the processing chamber. The high-voltage discharge electrode adopts parallel plate electrodes, the top electrode is installed on the inner side of the top 5 of the processing chamber, and the bottom electrode is installed on the inner side of the bottom 8 of the processing chamber. Use a ship to hoist the treatment bin into a certain water area to be treated. The depth of the treatment bin is 0.2-0.35 meters. Apply a high-power pulse with an intensity of 15KV, a bipolar rectangular wave, and a frequency of 60KHZ. The treatment duration is longer than After 1 second, the ship continues to move the treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com