Functional gradient material interface enhancing technology for shield driven tunnel concrete pipe sheet

A technology of functionally graded materials and shield tunneling, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., to achieve the effect of high overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with example and accompanying drawing.

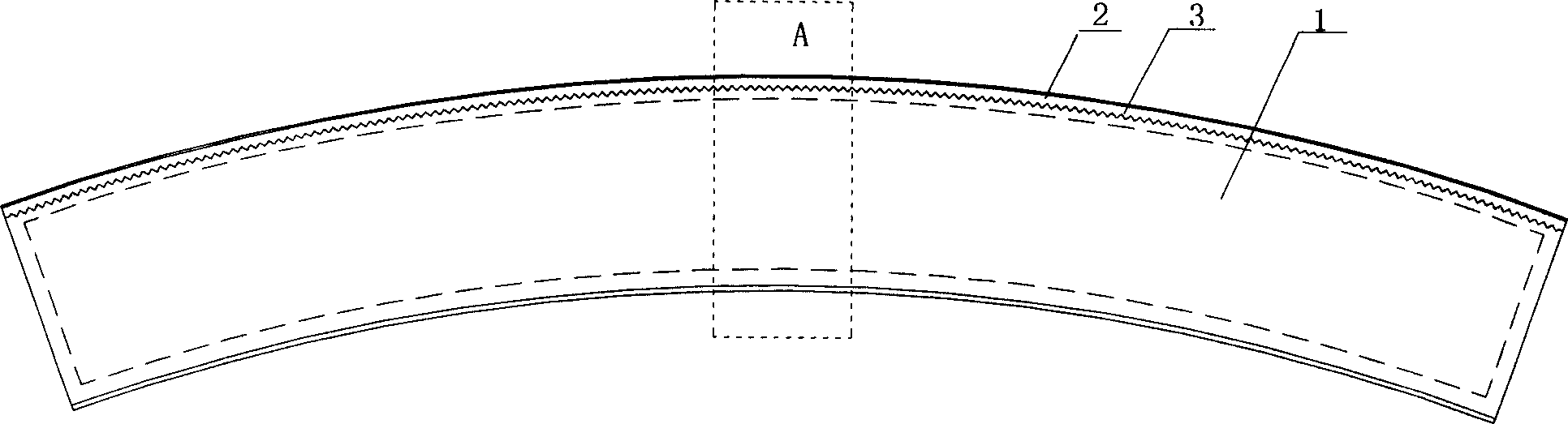

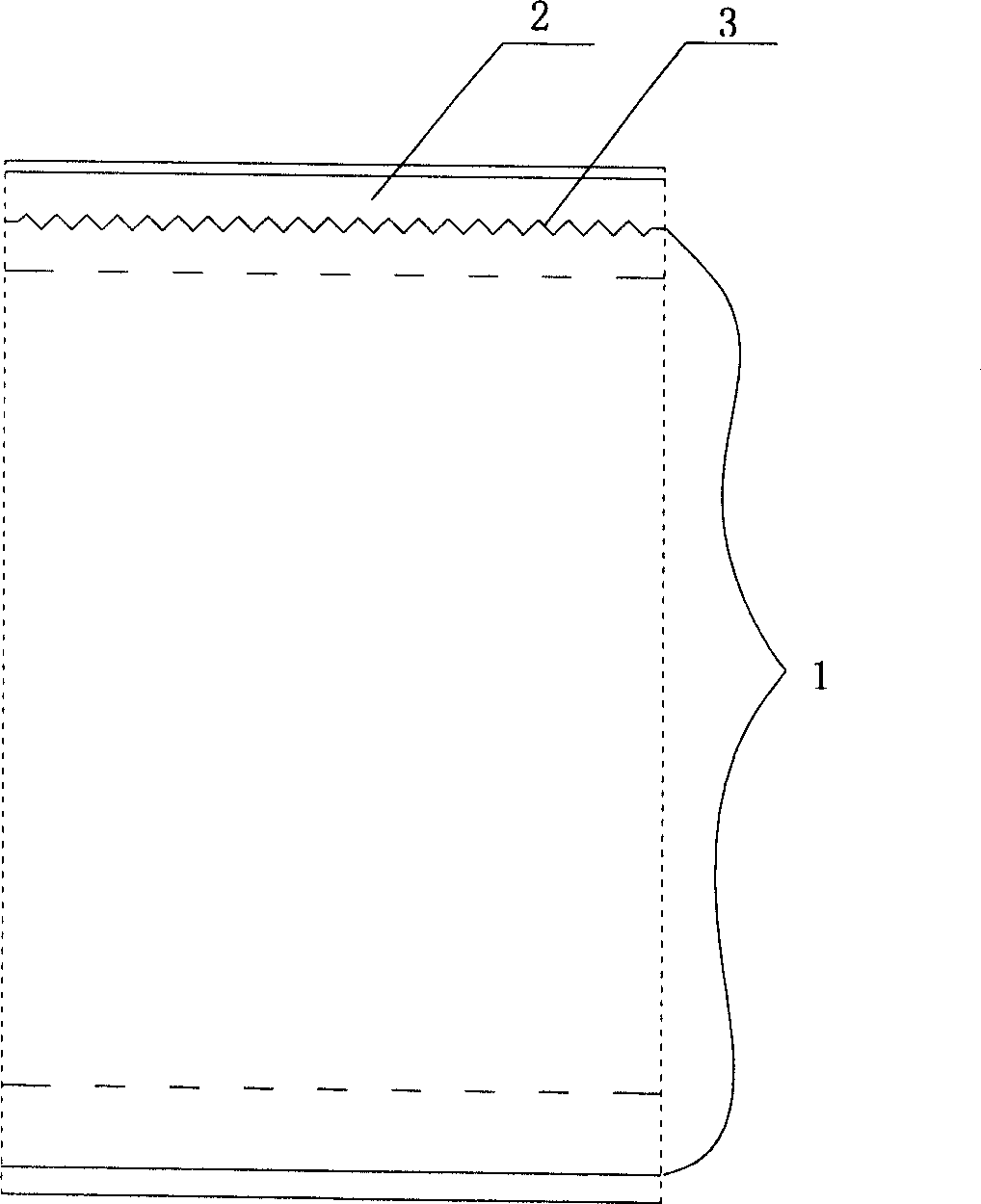

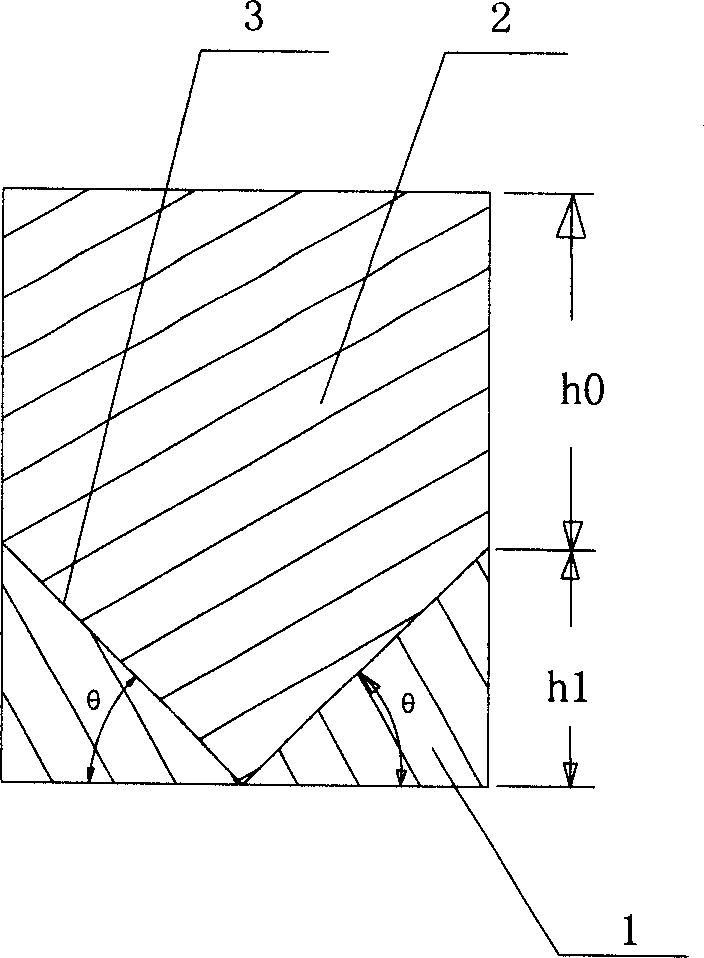

[0028] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the functionally graded material interface strengthening process of the shield tunnel concrete segment, the interface between the reinforced concrete structure layer 1 and the high impermeability protection layer 2 of the shield tunnel concrete segment is a functionally graded material interface, which includes the following steps:

[0029] 1) Pour high-performance concrete with a strength grade greater than C50 in the reinforced concrete segment steel mold to a distance of 15 to 80 mm from the surface of the steel mold, and then insert and tamp to form a reinforced concrete structural layer 1 with a thickness of 420.0 to 485.0 mm;

[0030] 2) Perform functionally graded material interface strengthening treatment: Emboss an embedded broken-line interface 3 on the upper surface of the reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diffusion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com