Drive circuit of low-noise brush-less DC. fan

A DC fan and drive circuit technology, applied in the direction of torque ripple control, etc., can solve the problems of inability to form a trapezoidal drive signal, power consumption, and poor operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

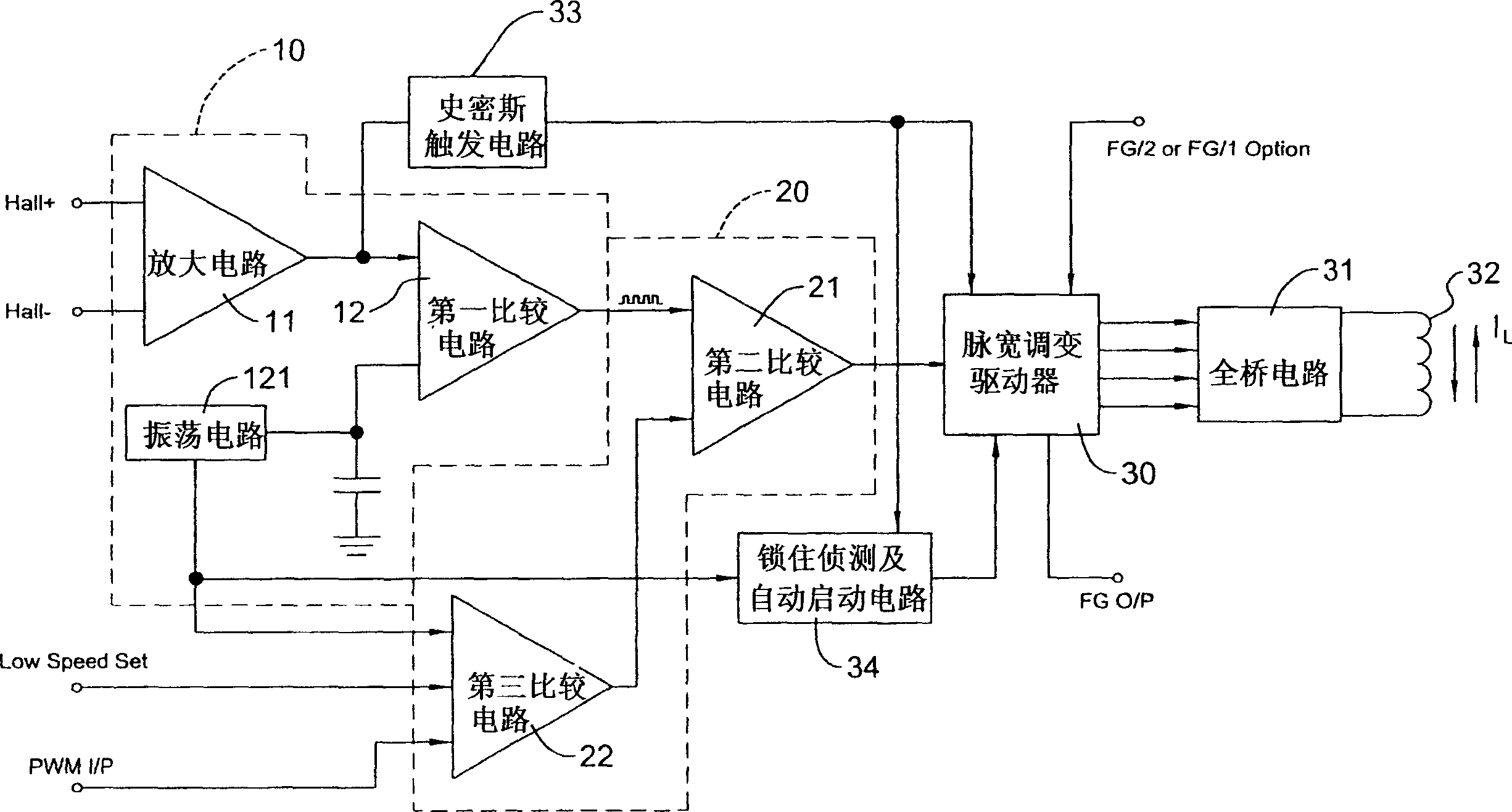

[0047] See first figure 1 As shown, it is a circuit block diagram of a preferred embodiment of the brushless DC motor drive circuit of the present invention, which mainly includes:

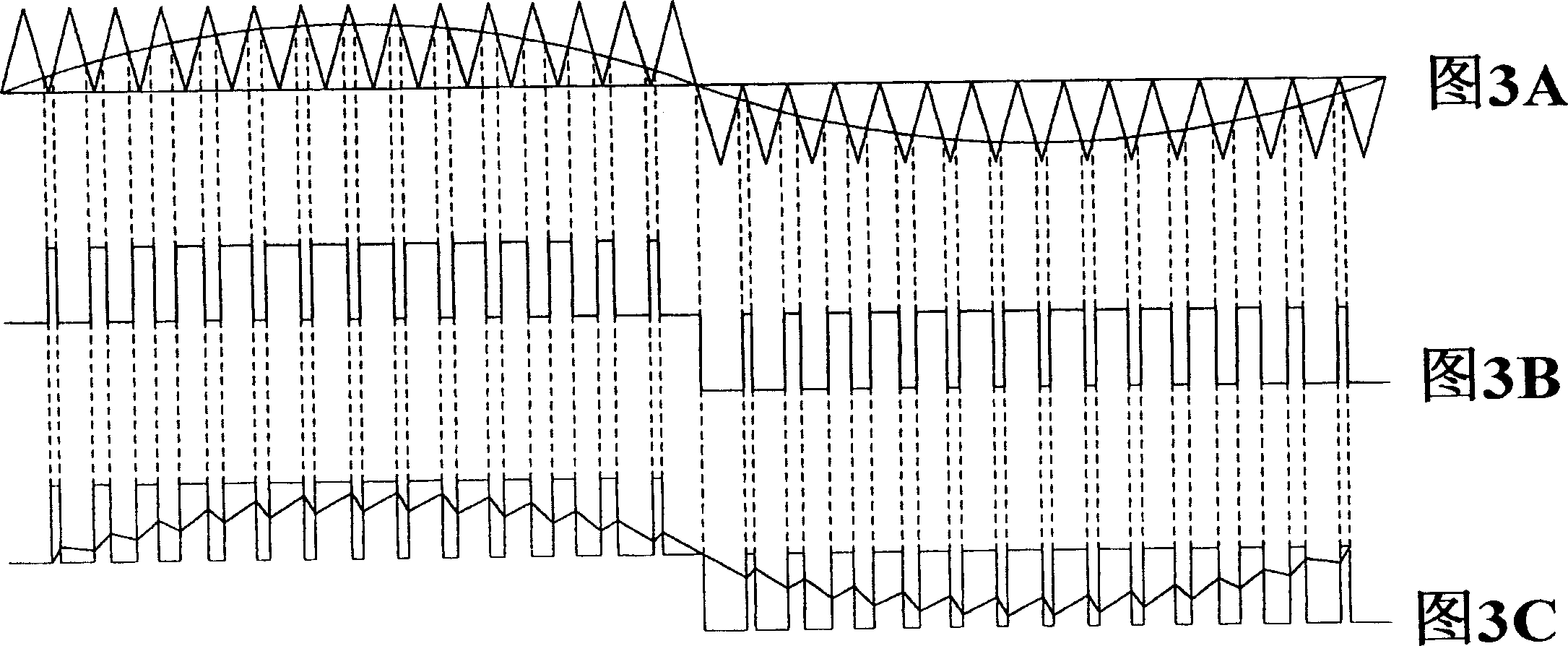

[0048] A Hall pulse width modulation signal generating circuit 10, which is not shown in the figure for the connection of the Hall sensor, converts the Hall sine wave signal Hall+ / Hall- into a pulse width modulation signal, and makes the pulse width modulation signal of the pulse width modulation signal Width modulation with the amplitude of the Hall sine wave signal;

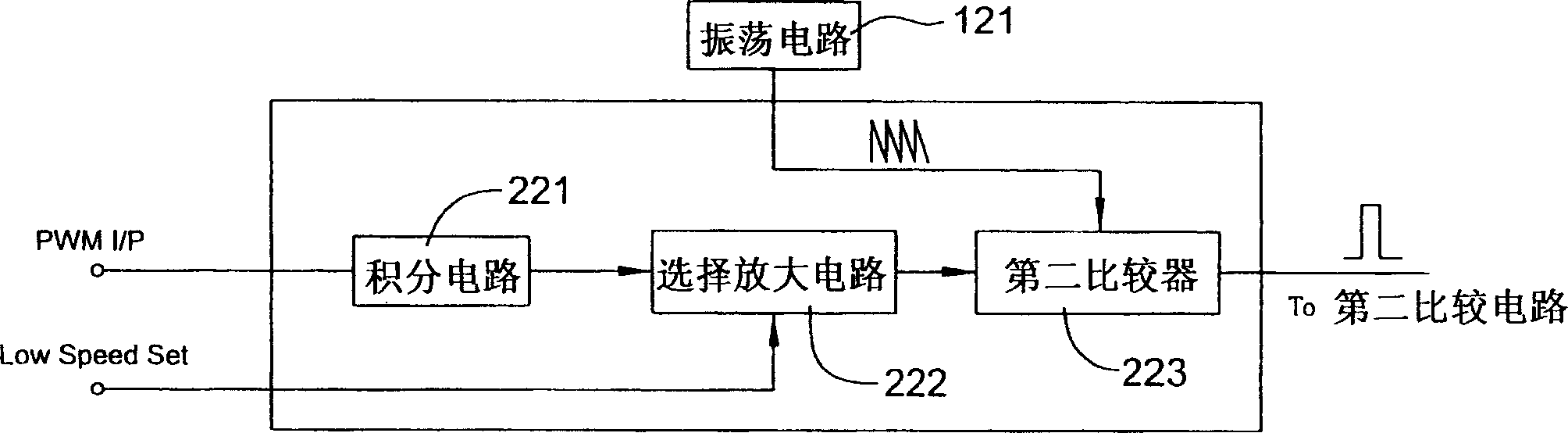

[0049] A rotational speed judging signal generation circuit 20 is connected to the output end of the Hall pulse width modulation signal generation circuit 10 to compare with the external PWM signal PWM I / P for controlling the rotational speed, so as to output pulses containing the rotational speed. Wide modulation signal SPWM;

[0050] A pulse width modulation driver 30, which includes a Hall signal input end, a SPWM signal inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com