Machine-room-less elevator apparatus

A machine room-less elevator and traction machine technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problem of rising product costs and construction costs, damage to the appearance of buildings, and the area and height of the top of the shaft. Increase and other problems, to achieve the effect of low price, reduction of equipment cost, and reduction of construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

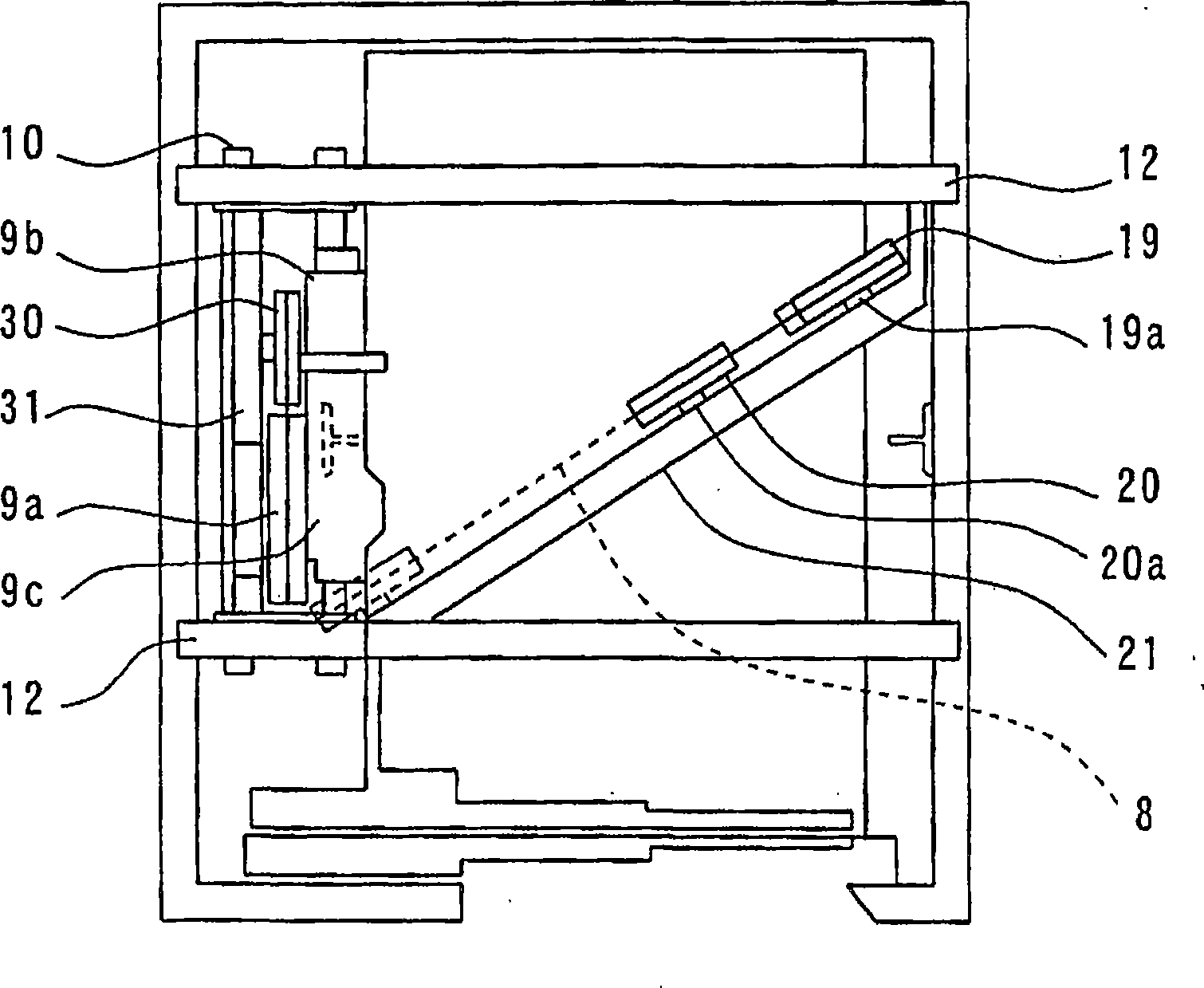

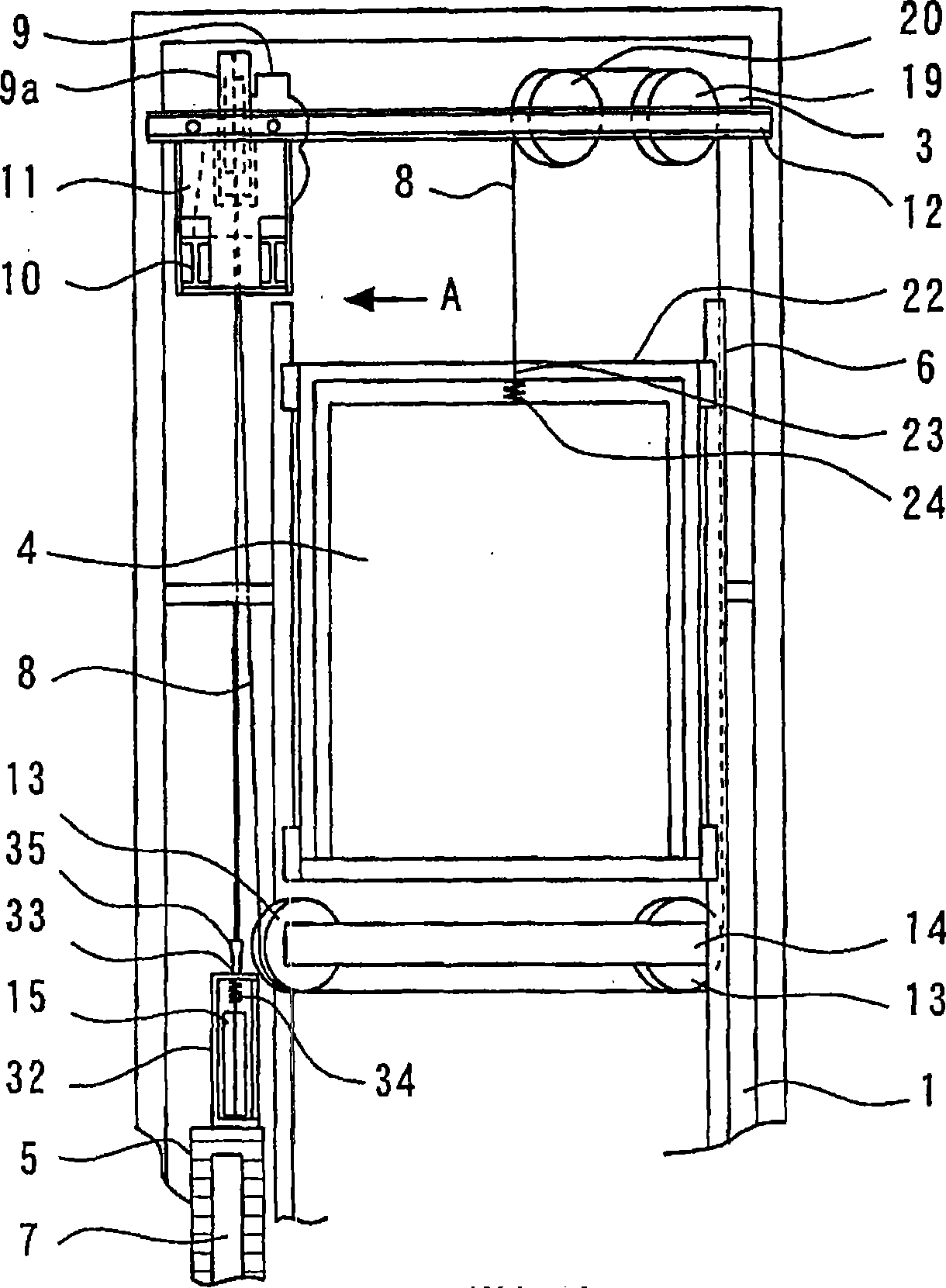

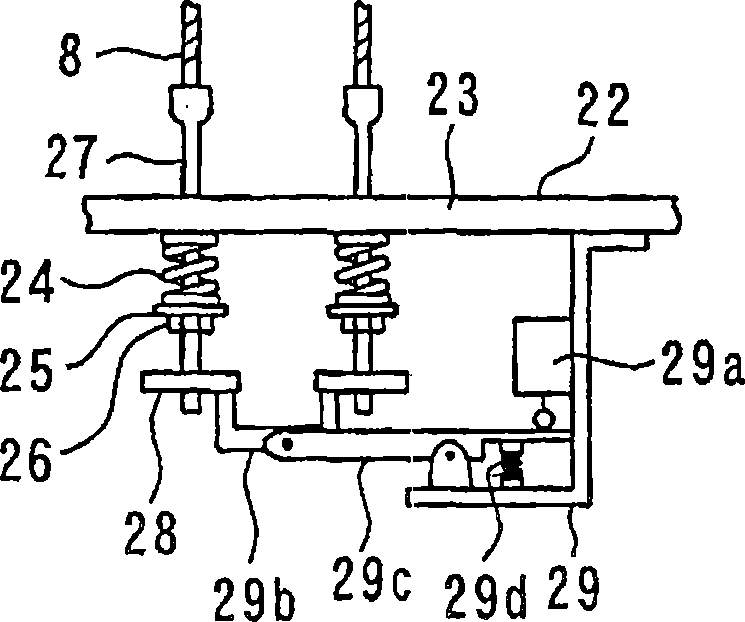

[0029] figure 1 It is a hoistway plan view showing the elevator device in Embodiment 1 of the present invention, figure 2 It is a front view showing the upper part of the hoistway of the elevator device in Embodiment 1 of the present invention, image 3 It is an enlarged view showing the weighing device provided on the car top beam of the elevator apparatus in Embodiment 1 of the present invention.

[0030]In the figure, 1 is the hoistway, 2 is the bottom pit of the hoistway, 3 is the top of the hoistway, 4 is the lift car in the hoistway 1; Heavy, 6 is the guide rail for the car that limits the movement of the car 4 along the horizontal direction, 7 is the guide rail for the counterweight that limits the movement of the counterweight 5 along the horizontal direction, 8 is the rope for suspending the car 4 and the counterweight 5, 9 It is a thin traction machine that drives the car 4 and the counterweight 5 through the rope 8 to make them go up and down. The hoisting mach...

Embodiment 2

[0034] Figure 4 is the slave representing the elevator device in Embodiment 2 of the present invention figure 2 The front view when the counterweight is raised as seen from the direction of arrow A in .

[0035] 36 is provided with two counterweight hanging wheels on the left and right sides of the upper part of the counterweight 5, and 37 is a counterweight rope holding part arranged at the center of the counterweight 5 top.

[0036] That is, the other end side of the rope 8 is such a structure: the rope 8 passes from the sheave 9a of the traction machine 9 through the left and right counterweight suspension pulleys 36 on the upper part of the counterweight 5, and a counterweight reversing sheave 30 on the hoistway top 3. , is arranged on the counterweight rope holding part 37 at the center of the upper part of the counterweight 5, thereby suspending the counterweight 5. Thus, the same 3:1 roping system as in the first embodiment described above is constituted.

Embodiment 3

[0038] Figure 5 is the slave representing the elevator device in Embodiment 3 of the present invention figure 2 The front view when the counterweight is raised as seen from the direction of arrow A in .

[0039] 38 is two counterweight hanging wheels arranged on the left and right sides of the counterweight 5 bottom, and 39 is a counterweight rope holding part arranged at the top center of the counterweight 5 .

[0040] That is, the other end side of the rope 8 is such a structure: the rope 8 passes from the sheave 9a of the traction machine 9 through the left and right counterweight suspension pulleys 39 at the bottom of the counterweight 5, and a counterweight reversing sheave 30 at the hoistway top 3. , is arranged on the counterweight rope holding part 39 at the center of the upper part of the counterweight 5, thereby suspending the counterweight 5. Thus, the same 3:1 roping system as in the first embodiment described above is constituted.

[0041] As described above,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com