Vacuum cleaner

A vacuum cleaner and electric technology, which is applied in the installation of vacuum cleaners, electrical equipment, and motor fan components. Effect of input power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

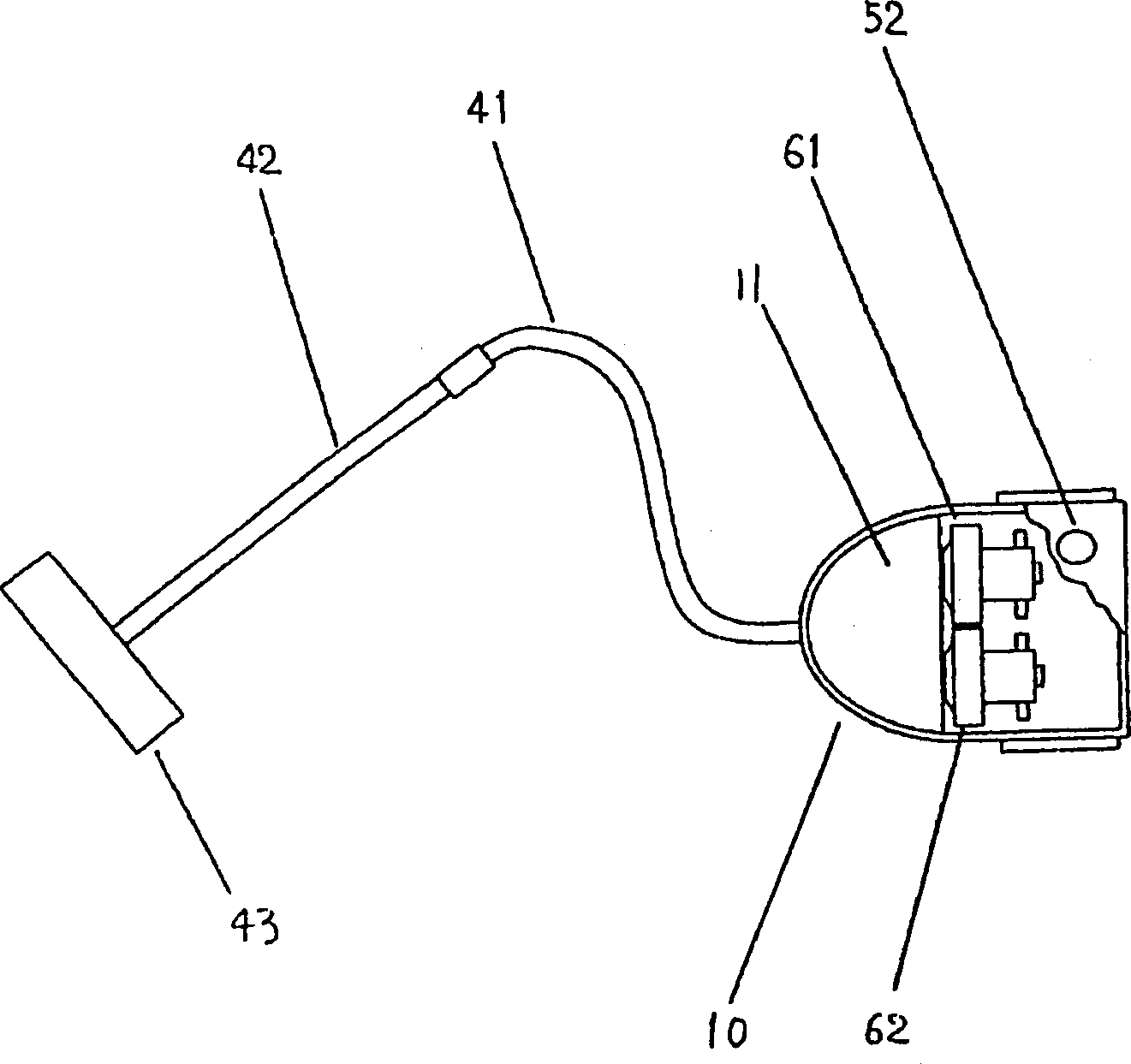

[0044] first use Figure 1 ~ Figure 3 The first embodiment of the present invention will be described. Wherein, for the same components as those in the above prior art, only the same symbols are marked below, and repeated description thereof will be omitted.

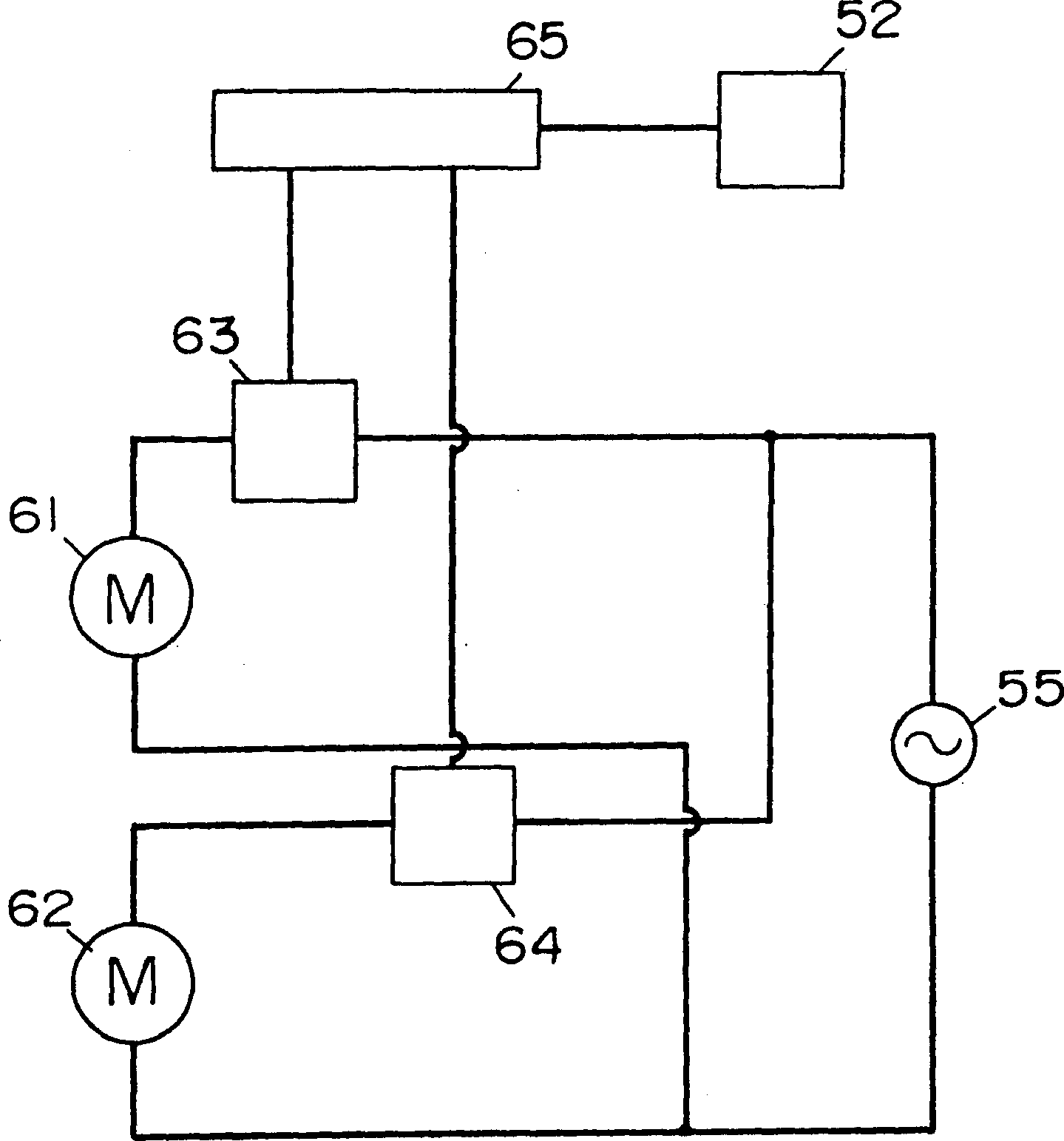

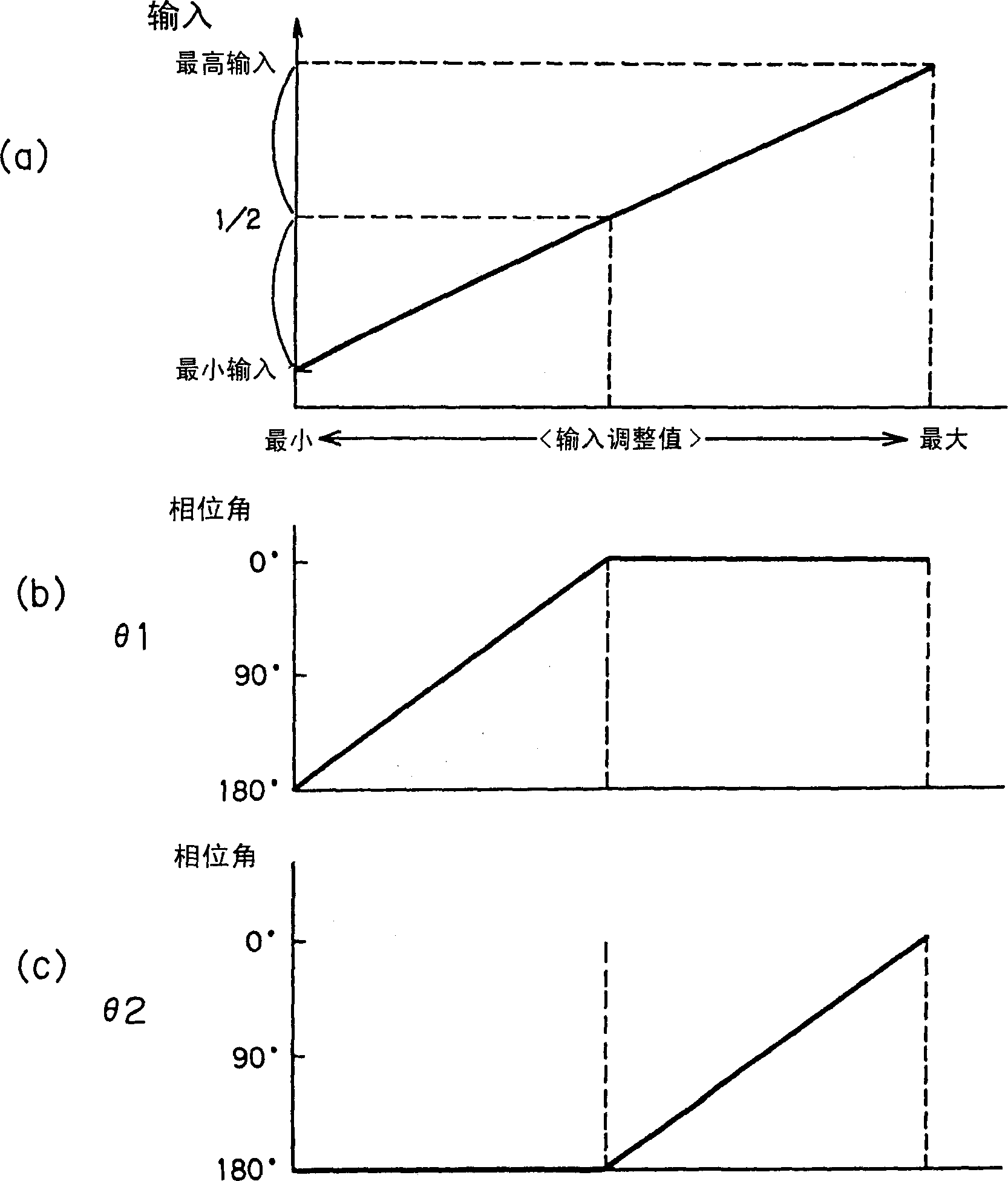

[0045] figure 1 To show the oblique view of the electric vacuum cleaner of the present embodiment, figure 2 Its circuit block diagram, image 3 A graph of the relationship between the input adjustment value and the control state of the electric fan.

[0046] Such as figure 1 As shown in , the electric vacuum cleaner 10 is provided with a first electric blower 61 and a second electric blower 62 . The total value of the maximum power of the first electric fan 61 and the second electric fan 62 is about 1600W or higher, that is, the maximum power consumption of the electric vacuum cleaner 10 is more than 1600W. The suction ports of the electric fans communicate with the dust collecting chamber 11 in the electric vac...

Embodiment 2

[0050] Use below Figure 4 A second embodiment of the present invention will be described. Wherein, for the same components as those in the prior art, only the same symbols are attached here, and their detailed descriptions are omitted.

[0051] Figure 4 It is a relationship diagram between the input adjustment value of the electric vacuum cleaner and the control state of the electric fan in this embodiment.

[0052] The input range in which the electric vacuum cleaner can work is the range between the lowest input value and the highest input value. Before vacuuming, the user first sets the input to the desired value, and then makes the vacuum cleaner perform the vacuuming operation. When operating the electric vacuum cleaner, desired power supply power is applied to both the first electric blower 61 and the second electric blower 62 . Assuming that the energized phase angle of the first electric fan 61 is controlled by the first control device 63 to be θ1, and the energi...

Embodiment 3

[0056] Use below Figure 5 Now, the third embodiment of the present invention will be described. Wherein, for the same components as those in the existing device, only the same symbols are assigned below, and repeated description thereof will be omitted.

[0057] Such as Figure 5 As shown in , the electric vacuum cleaner 10' is provided with a first electric blower 61 and a second electric blower 62, the suction port of the first electric blower 61 communicates with the dust collection chamber 11 in the electric vacuum cleaner 10', and the second electric blower 62 is provided on the downstream side of the first electric fan 61 . The first electric blower 61 and the second electric blower 62 are controlled according to the control method in the above-mentioned embodiment 1 or embodiment 2.

[0058] With the above-mentioned structure, after the electric fan is arranged in series in the electric vacuum cleaner, the vacuum pressure of the electric fan can be increased when tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com