Three-dimensional feet data measuring method to sparse grid based on curve subdivision

A sparse grid and surface subdivision technology, applied in image data processing, image data processing, diagnostic recording/measurement, etc., can solve the problems of costly post-processing time, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

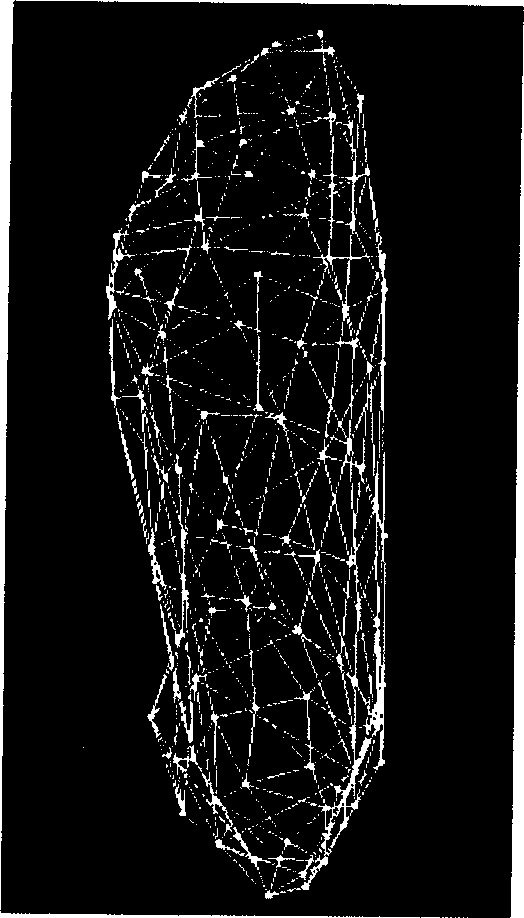

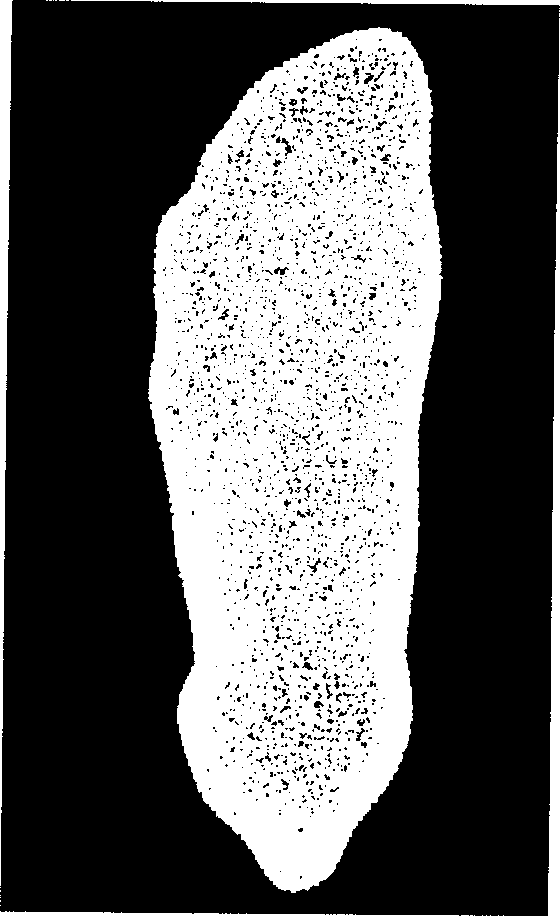

[0050] First, load the sparse mesh foot model, see Image 6 . Since the loaded sparse grid foot model cannot be used for direct measurement, it can be seen in the figure that it has many edges and corners. If it is measured directly, it will cause a large error, and the obtained data is basically unusable. For use in shoemaking. Therefore, it needs to be subdivided to turn this sparse grid foot model into a three-dimensional feature foot model, see the attached Figure 7. After such transformation, we can see that the edges and corners in the sparse grid foot model have disappeared, and such data can be used for measurement. In the next step, project the generated 3D foot model onto the XOY plane, see attached Figure 8 , to get the proportion map of the outline of the foot. After observation, we found that all the foot shape parameters for shoemaking can be calculated by only getting the seven feature points on the foot shape. The seven characteristic points are: the ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com