Production of carbon nano-tube array

A carbon nanotube array and fabrication method technology, which is applied in the field of directional controllable carbon nanotube array fabrication, can solve the problems of increasing the complexity of device design and difficult to achieve control, and achieves the effects of enriching design diversity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

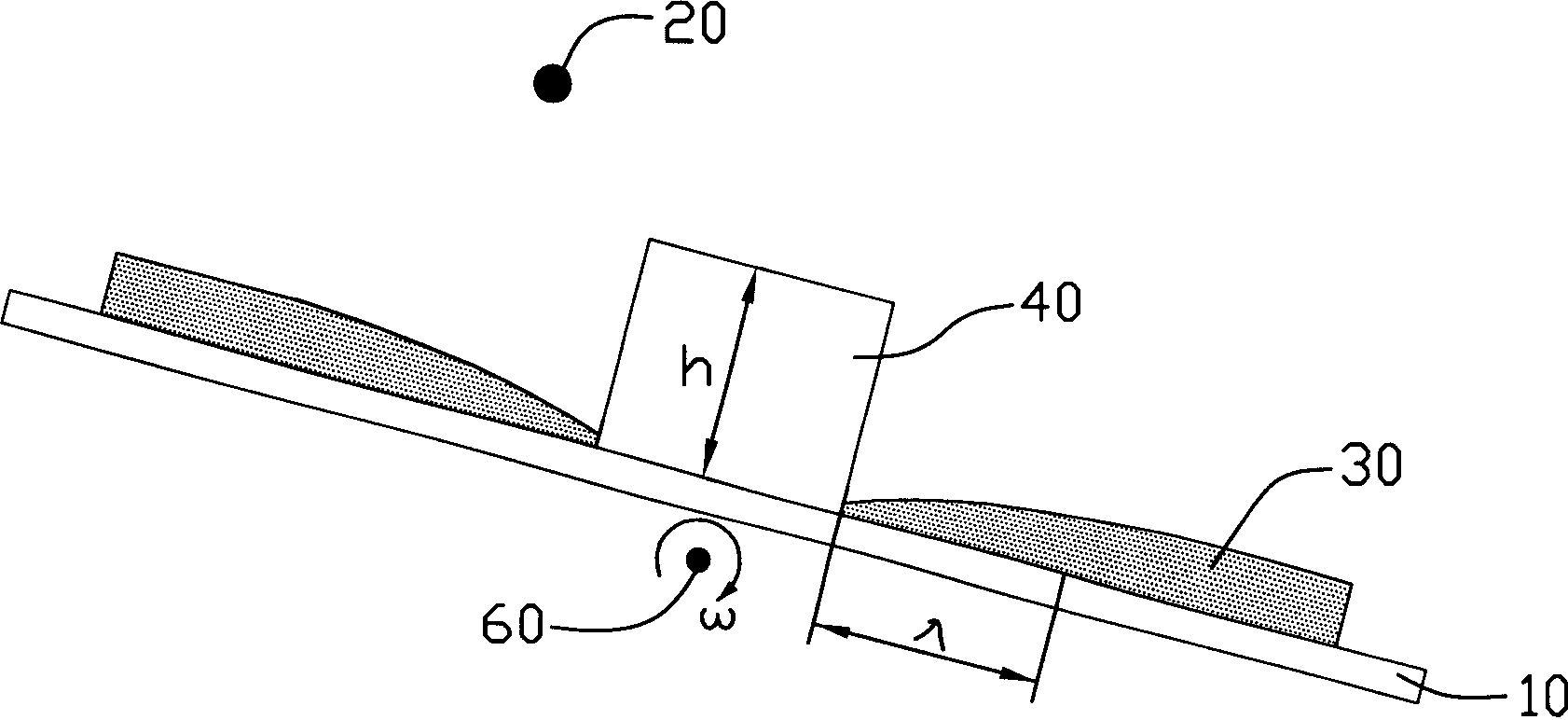

[0039] see figure 1 , the carbon nanotube array manufacturing method provided by the first embodiment of the present invention includes the following steps:

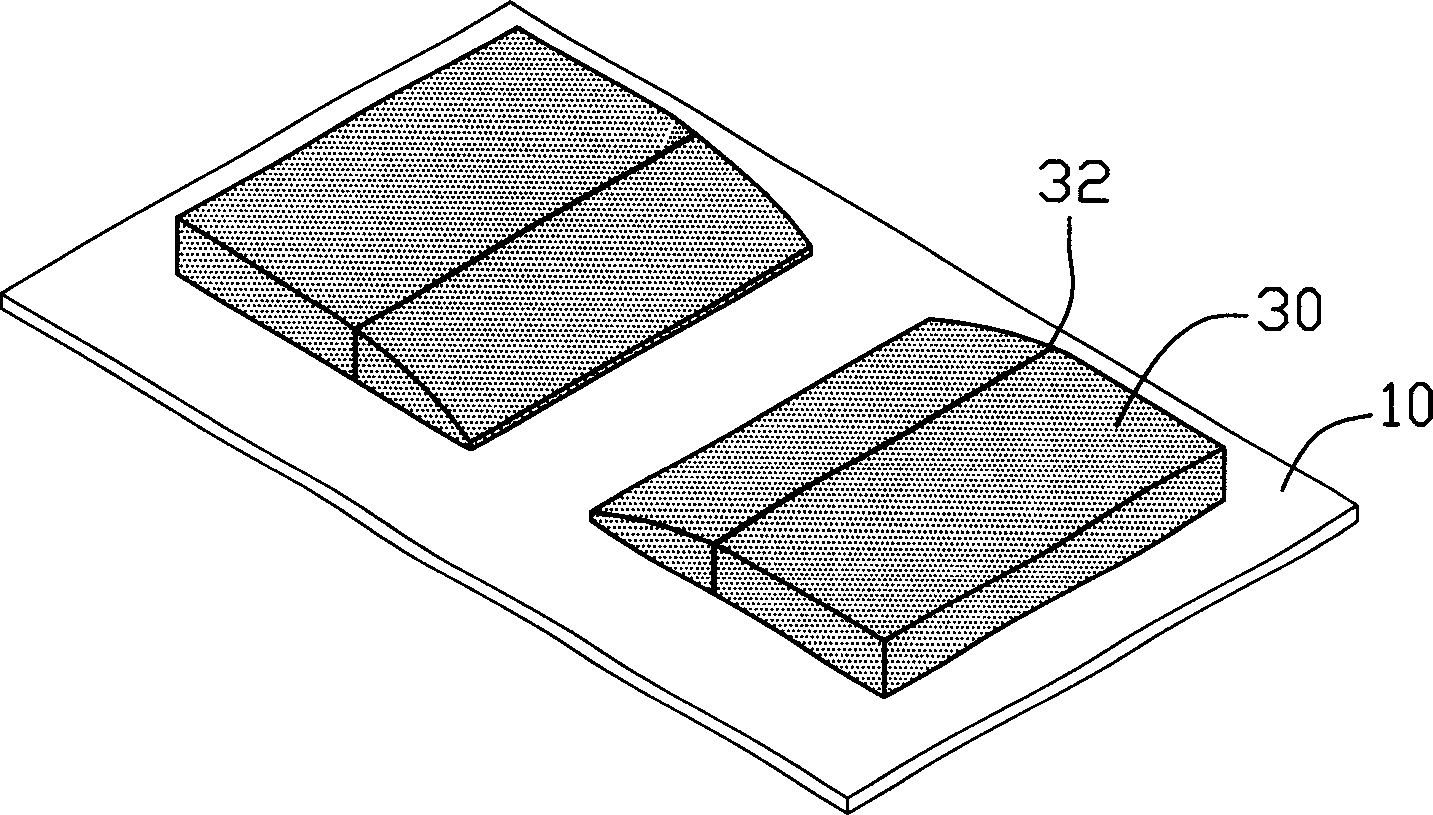

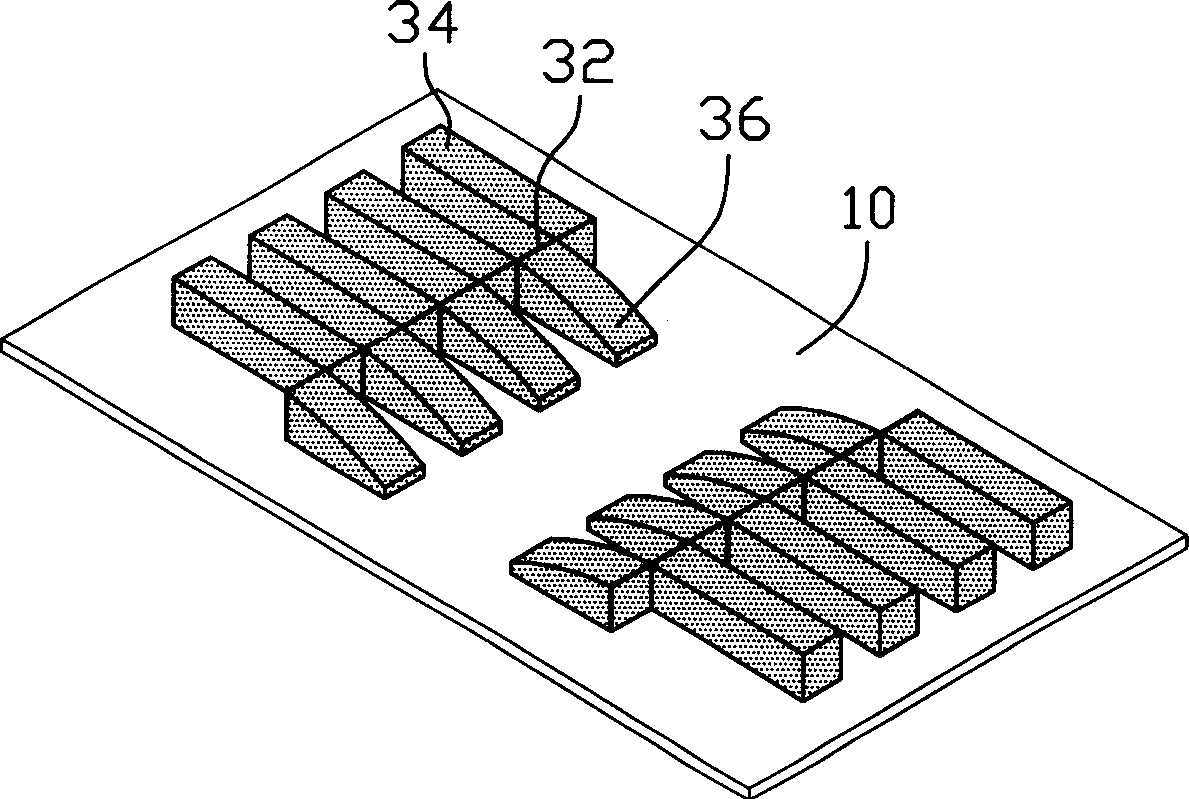

[0040] (1) Provide a base 10 on which a shielding layer 40 with a certain thickness is formed. The substrate 10 can be a silicon wafer, a glass wafer, a metal wafer, etc.; a silicon wafer is used in this embodiment. The shielding layer 40 has a vertical shielding edge with a certain height, which is the thickness of the shielding layer 40, so that the shielding layer 40 can shield the part of the catalyst evaporated from the point evaporation source 20, so that the thickness of the obtained catalyst film 30 has a certain thickness range. The gradient of the inner gradient. The shielding layer 40 can be made of thick film photoresist, metal or metal oxide, metal nitride attached to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com