No.2-type opening absorbing water pump

An absorption heat pump and heat pump technology, applied in heat pumps, lighting and heating equipment, refrigeration components, etc., can solve the problems of huge investment in equipment, low temperature, and unfavorable increase in waste heat temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

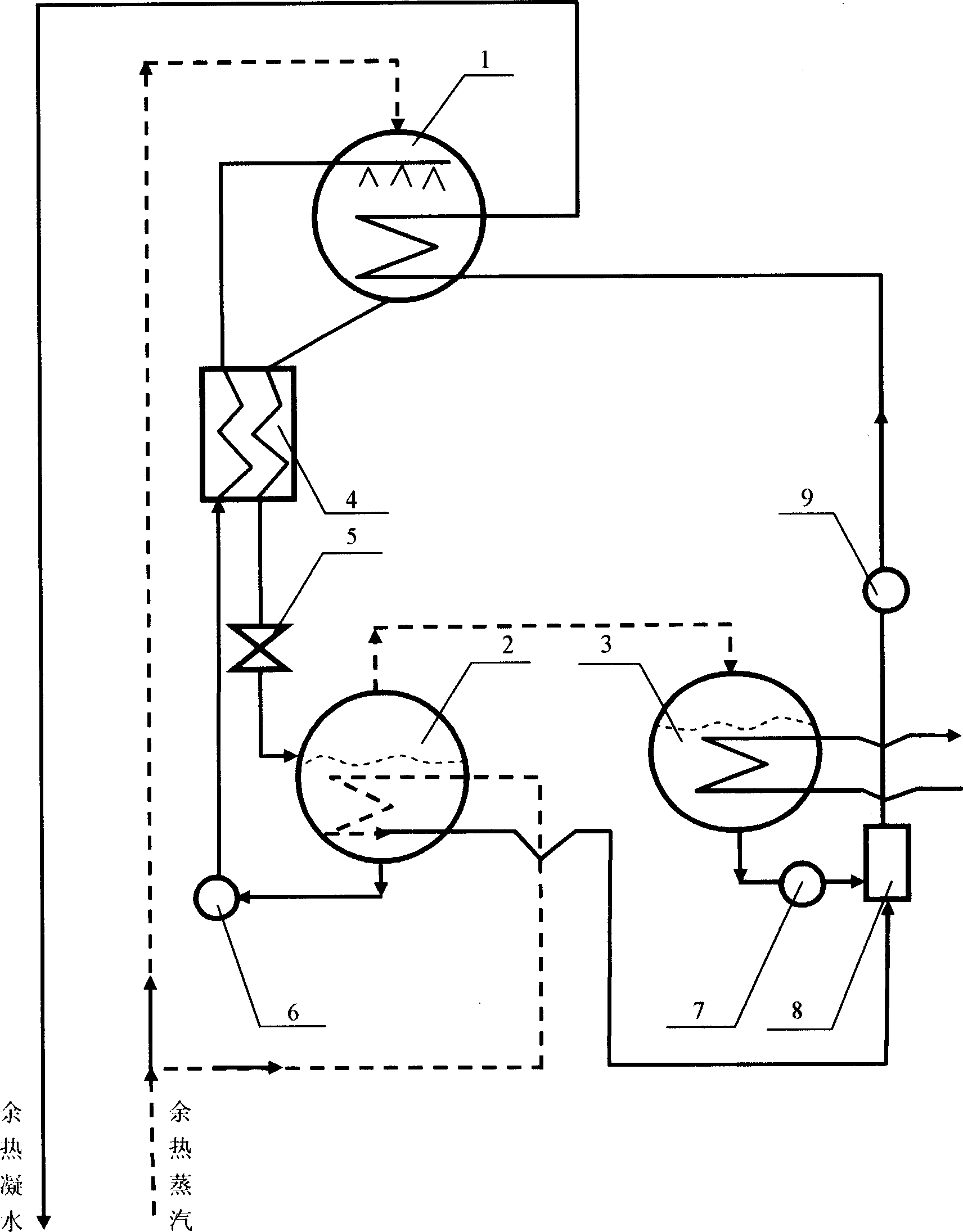

[0021] figure 1 Shown is the structure and process of the single-stage open type II absorption heat pump system in which exhaust steam enters the generator and absorber respectively, and the waste heat heats up by itself. Structurally, this type of heat pump system is mainly composed of absorber 1, generator 2, and condenser 3, and the evaporator in the second type of closed absorption heat pump system is omitted. Part of the waste heat steam enters the generator 2 to heat the dilute solution from the absorber to generate refrigerant steam; another part of the waste heat steam enters the absorber 1 to be absorbed by the concentrated solution from the generator 2. The solution from the absorber 1 enters the generator 2, where it is heated by waste heat steam, releases refrigerant vapor and enters the condenser 3 to be condensed into a liquid state by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com