Multifunctional friction-generating floor leather and sensor

A technology for triboelectric power generation and floor leather, which is used in triboelectric generators, floors, covering/lining, etc., can solve the problems of complex structure, high price and high cost of power generation carpets, and achieves diversified energy drive forms, easy preparation, and high structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. The structure of multifunctional friction power generation floor leather and independent sensor

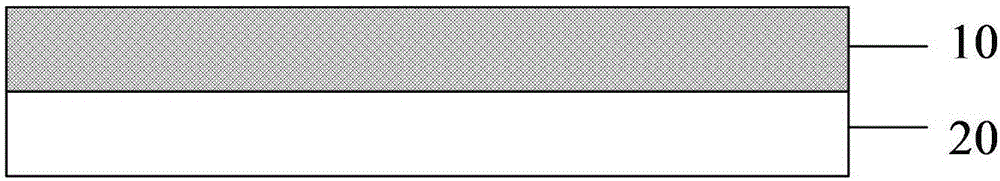

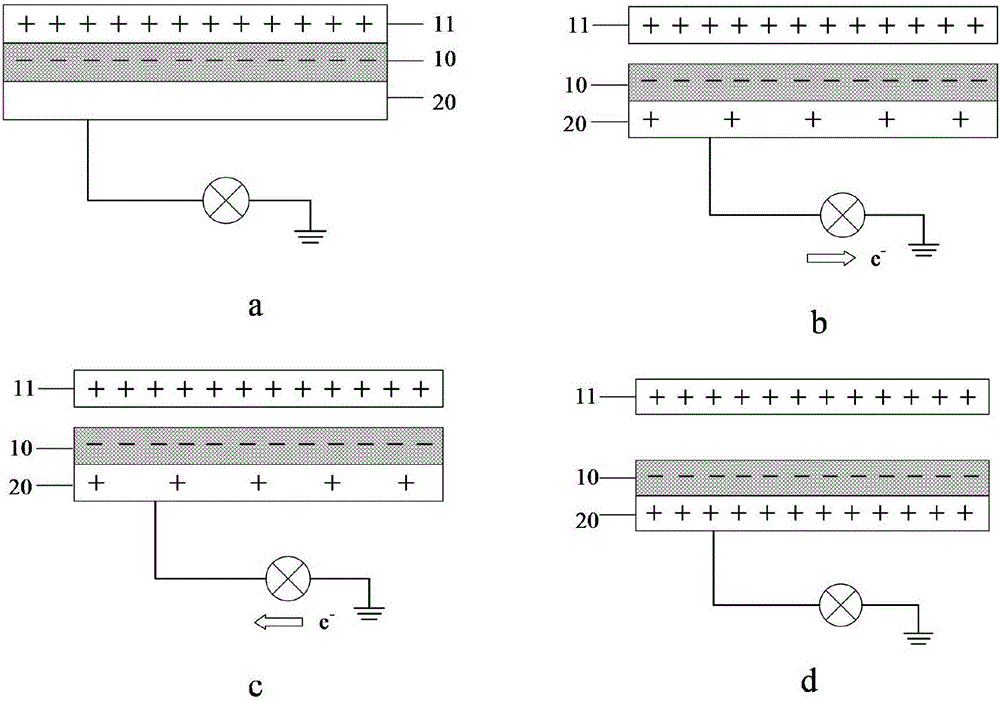

[0037] figure 1 It is a schematic cross-sectional view of a typical structure of the multifunctional friction power generation floor leather of the present invention. It includes: a floor leather body 10 and a conductive layer element 20 . By bonding, sputtering or electroplating, the conductive layer and the lower surface of the floor leather are combined into an integrated structure on the same plane. People's soles, clothes, tires and other materials that can generate frictional electrification with the surface of the floor leather can act as the second friction surface 11, and under the action of external forces such as beating, trampling, stroking, friction, etc. And the conductive layer element 20 transmits electrical signals to the external circuit. The conductive layer element can be located on the lower surface of the floor leather body 10 or between the laye...

Embodiment 2

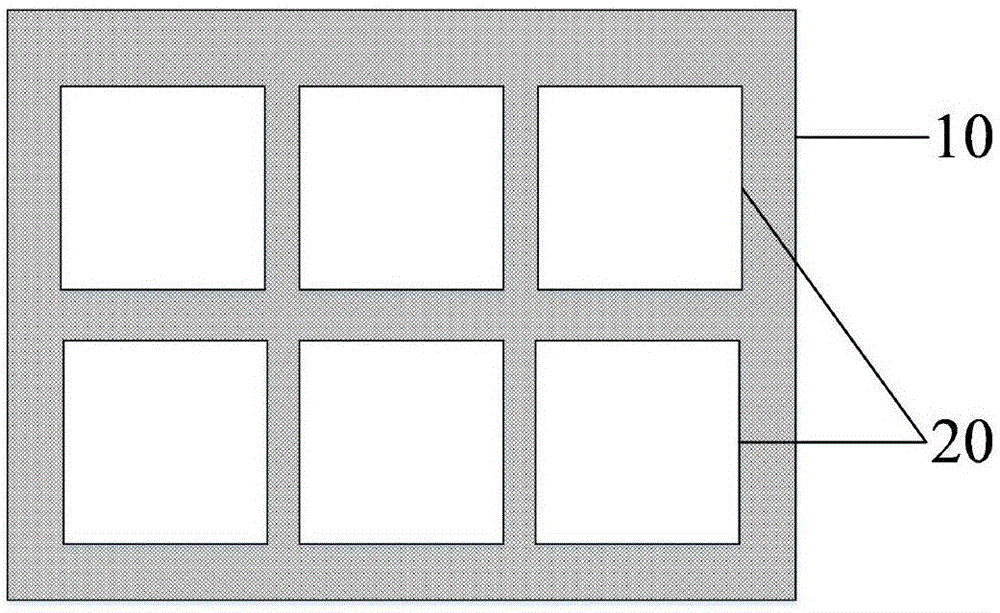

[0041] A kind of multi-functional friction power generation floor leather is provided in this embodiment, please refer to the attached Figure 4 . The floor leather body 10 in this embodiment is selected from composite coiled PVC floor leather with a thickness of 2mm. The conductive layer element 20 is selected as copper foil with strong conductivity, and its thickness is 80 μm. The conductive layer element 20 and the floor leather body 10 in this embodiment are prepared by simple bonding, and the size of the triboelectric floor leather is 4cm*9cm. In this embodiment, the nitrile glove is used as the second friction layer, and the energy is driven by slapping. The multifunctional friction power generation floor leather generates current to the outside. The current data displayed by the electrometer 6514 test can be found in the appendix Figure 6 , the voltage data graph is shown in Figure 7 shown.

Embodiment 3

[0043] This embodiment provides a multi-functional triboelectric floor leather. As a sensor, the floor leather body 10 in this embodiment is selected from coiled plastic floor leather with a thickness of 5mm. The conductive layer element 20 is selected as copper foil with strong conductivity, and its thickness is 80 μm. The conductive layer element 20 and the floor leather body 10 in this embodiment are prepared by simple bonding. In this embodiment, the second friction layer of the shoe sole is used for energy driving in various motion modes. The multifunctional friction power generation floor leather generates voltage signals to the outside, and the rules and differences of the voltage signal waveforms generated according to different actions. The multifunctional floor leather As an independent sensor, human body activity recognition can be carried out, and the voltage displayed by the electrometer 6514 test can be found in the attached Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com