Binocular active vision monitor suitable for precision machining

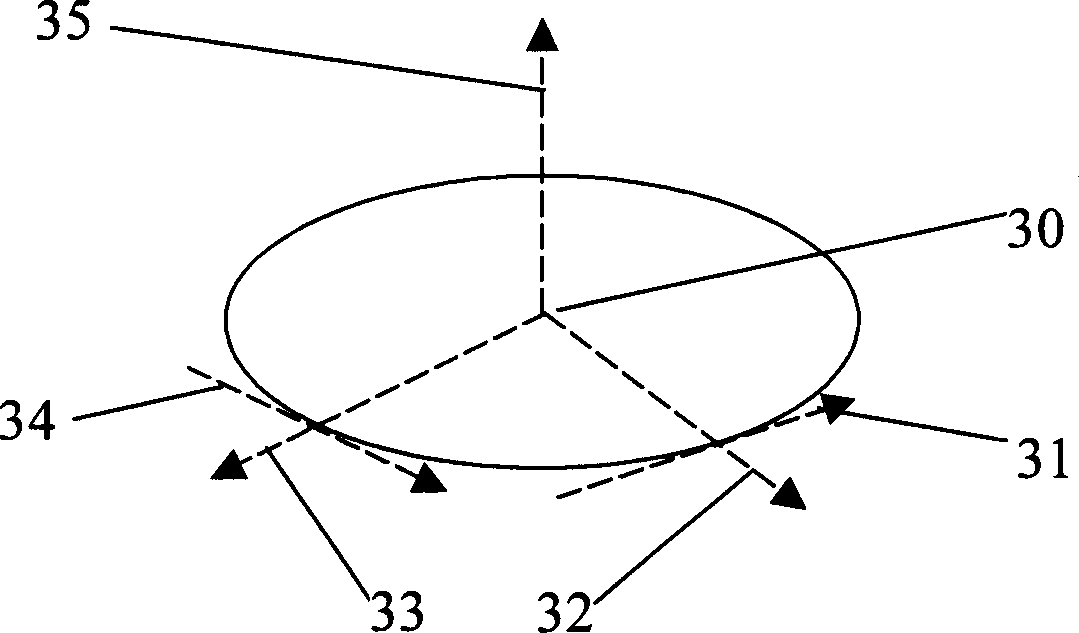

An active vision, precision machinery technology, applied in electrical program control, digital control and other directions, can solve the problems of limited viewing angle adjustment range, poor positioning accuracy, monitoring blind spots, etc., to achieve convenient modeling and calculation, easy description and expression, large scale. The effect of the range adjustment angle of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

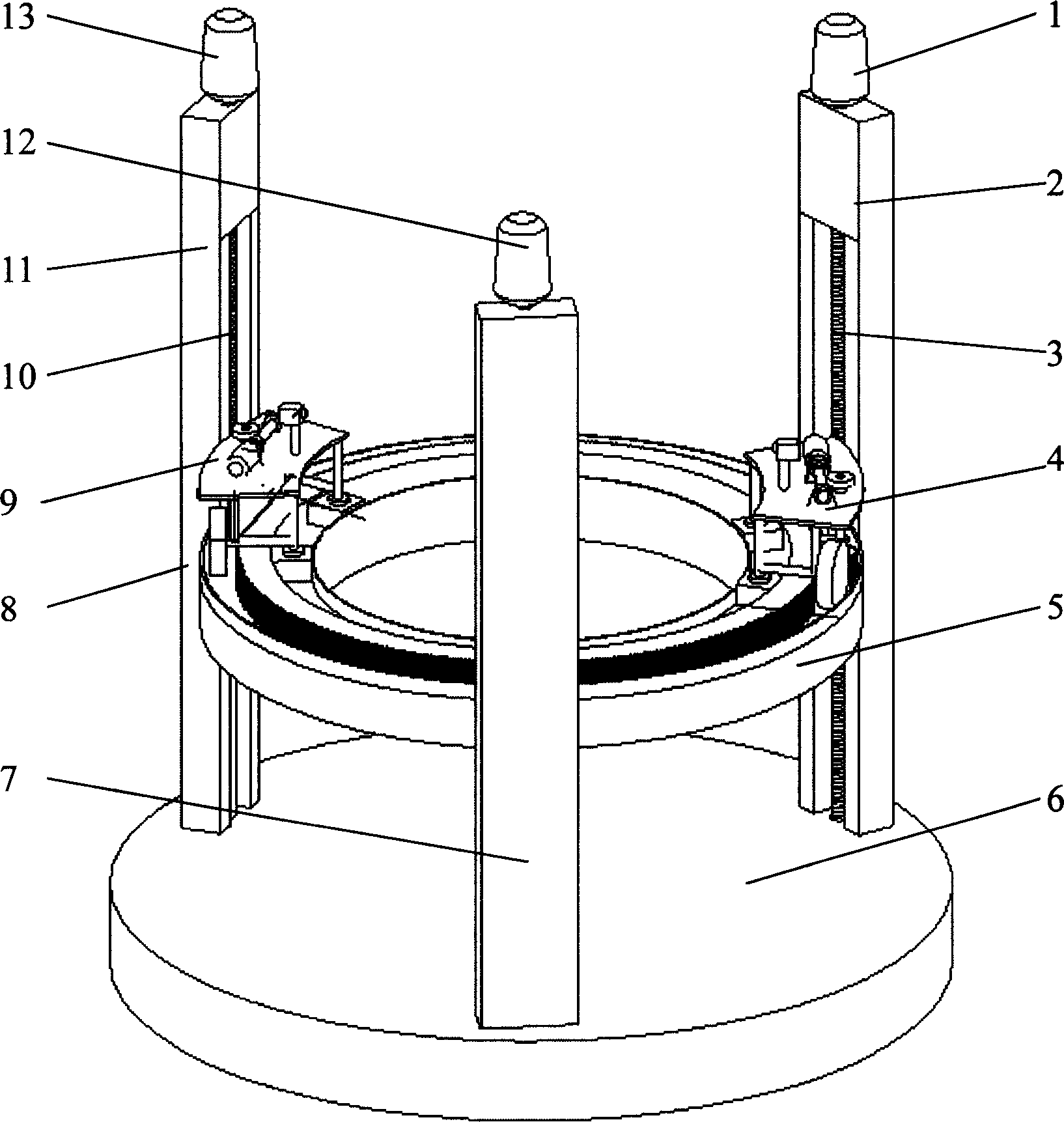

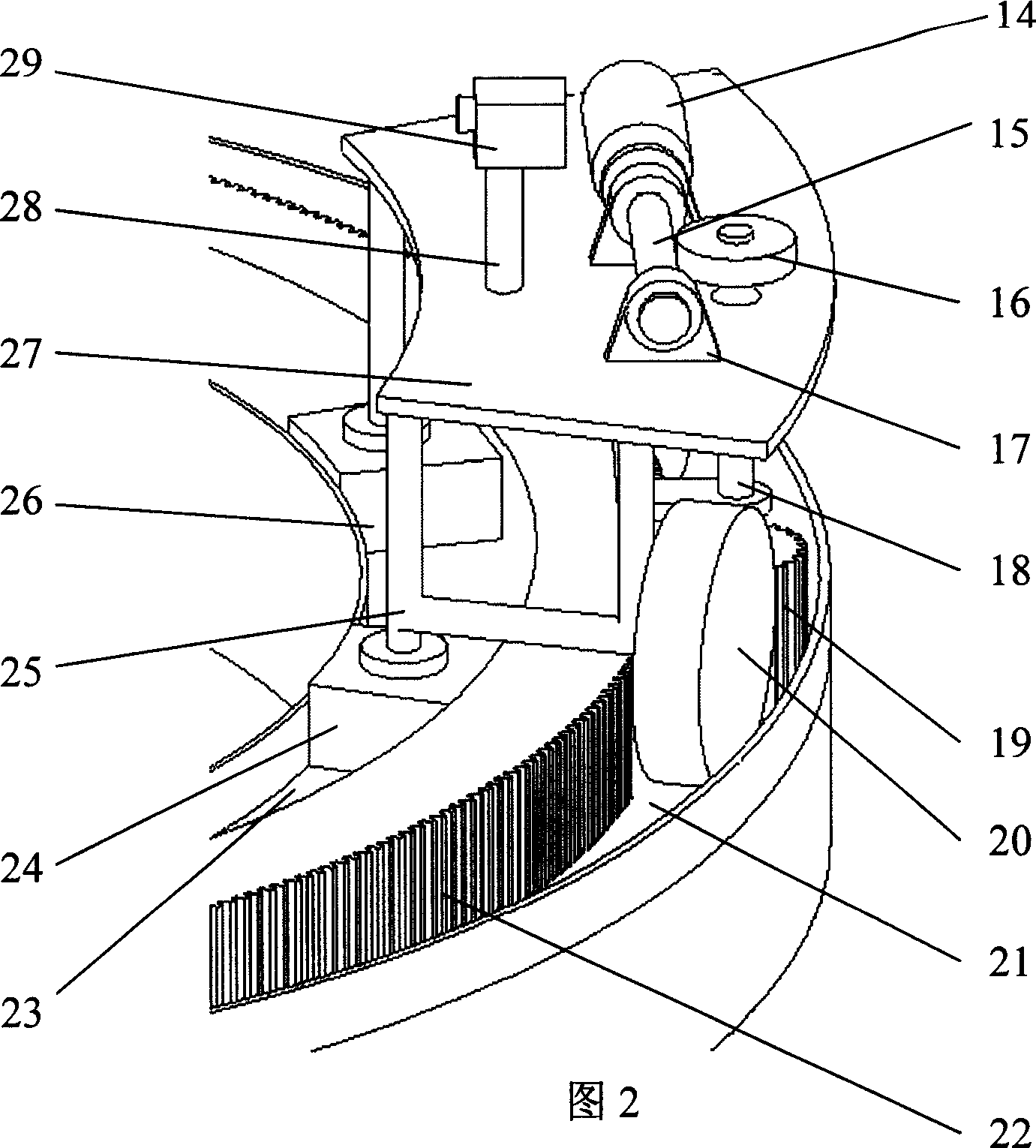

[0014] The binocular active visual monitoring device suitable for precision machining is independent of the parallel machine tool. Three symmetrically arranged brackets 2, 7, and 11 are fixed on the base 6. Each bracket is equipped with upper and lower slide rails, and each slide rail is connected to each other. Parallel and perpendicular to the plane of the base 6; slide blocks are installed on each slide rail, the upper and lower slide rails and slide blocks adopt screw nut structure, and lead screws 3 and 10 are installed in the three brackets (bracket 7 also has the same screw nuts as 3 and 10). lead screw), the slider 8 is processed with internal threads (the circular guide rail 5 and the brackets 2 and 7 have the same slider as 8), the circular guide rail 5 is fixedly connected with the three sliders 8, and the circular guide rail is kept parallel to the base flat. The stepping motors 1, 12, 13 are installed on the tops of the three supports 2, 7, 11, and the output ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com