Gyre cloth machine with gyration centre supporting apparatus

A technology of supporting devices and slewing centers, applied in the direction of supporting frames, conveyors, conveyor objects, etc., can solve the problems of low control level, poor rigidity and strength, poor stability and reliability, etc., and achieve high level of automation control and improve Good strength and rigidity, good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Hereinafter, the present invention will be further described in detail with reference to the drawings and specific embodiments.

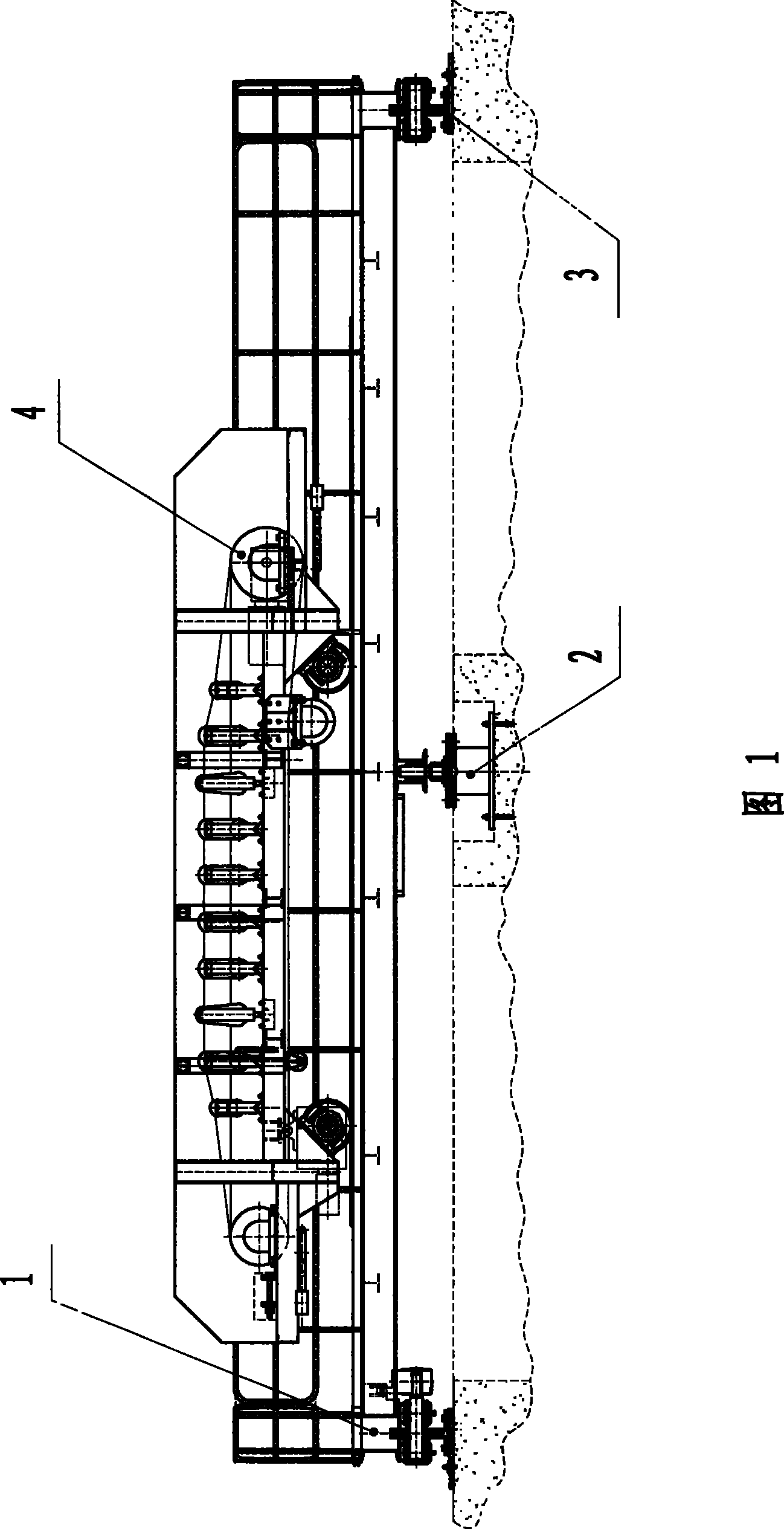

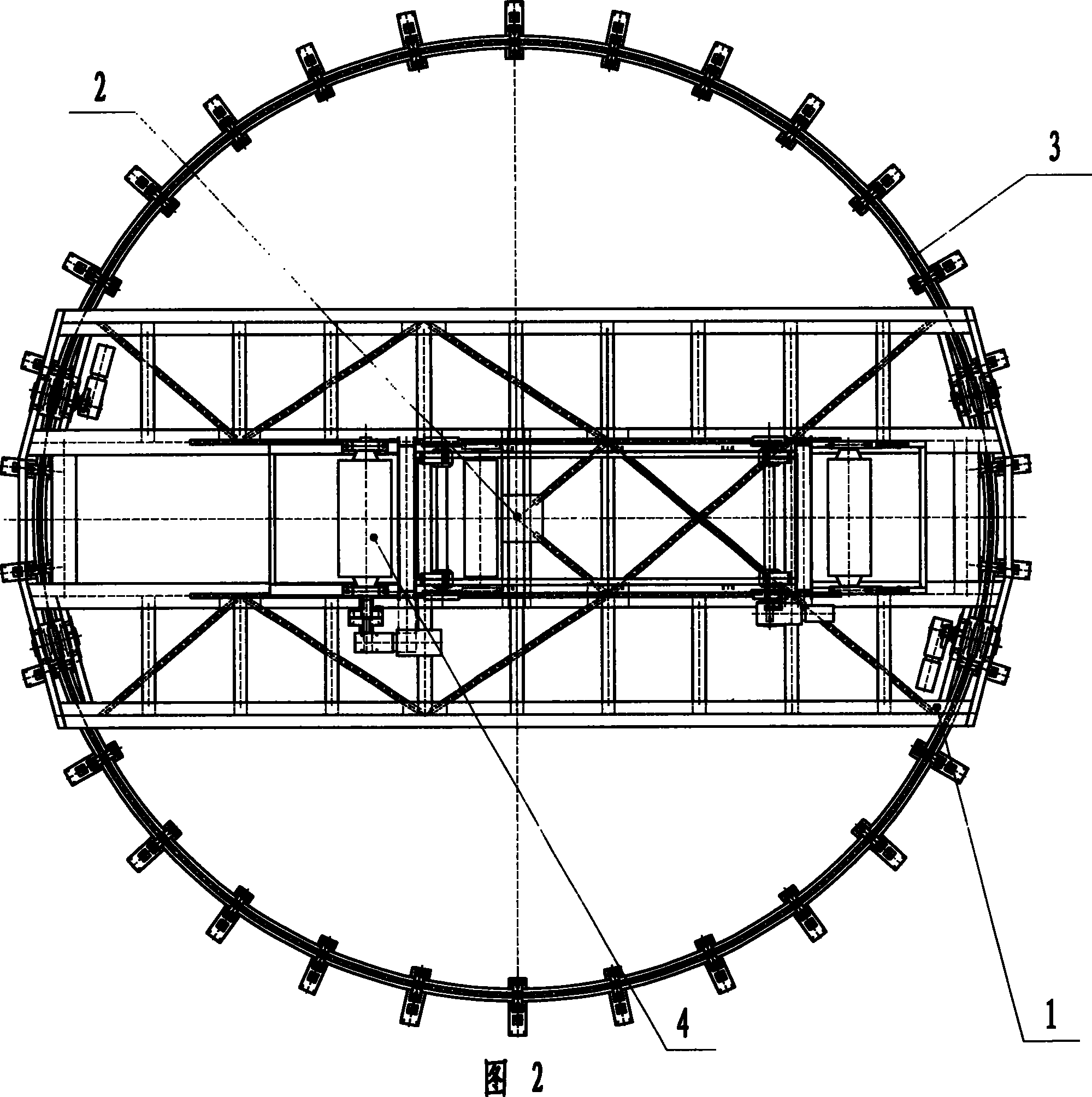

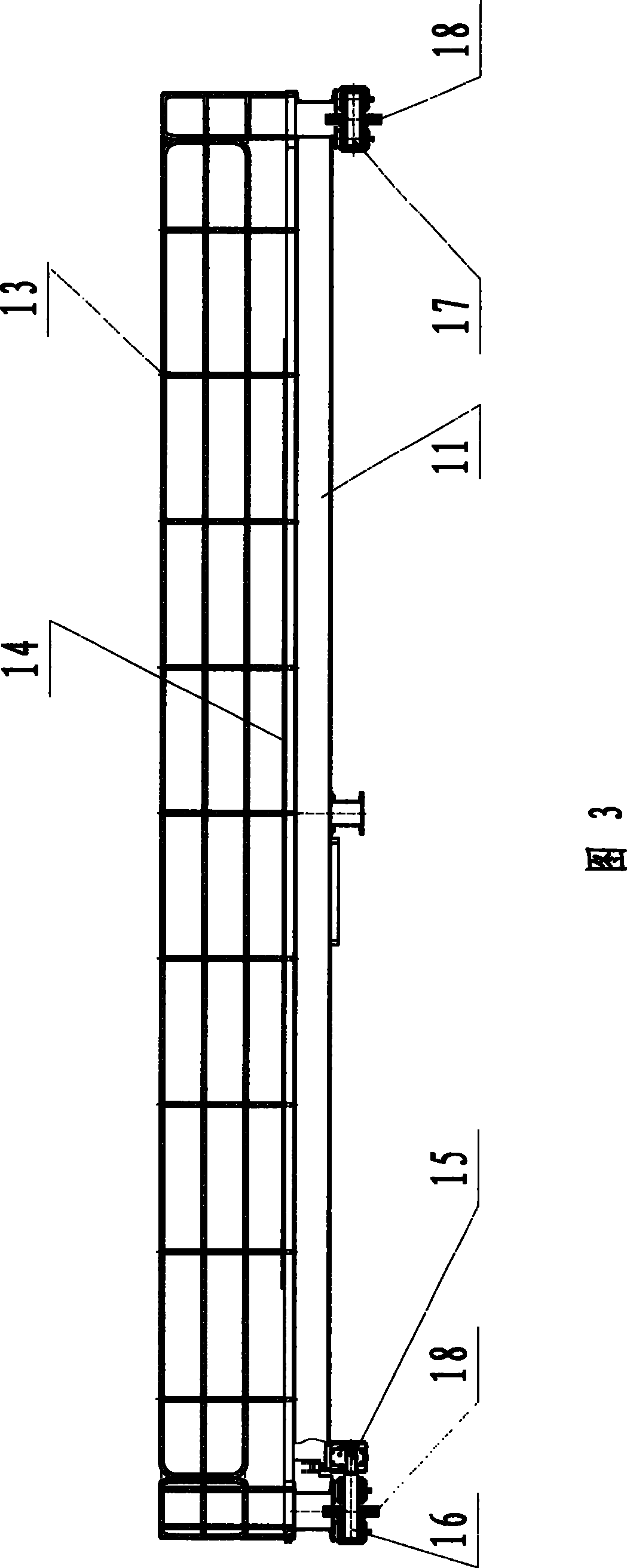

[0059] Such as figure 1 with figure 2 As shown, the rotary distributing machine of the present invention includes a rotary traveling cart and a driving device 1, an annular track 3, a reversible moving belt conveyor 4, and a control system 5. The annular track 3 is fixed to the annular concrete beam at the top of the tube tower. Above, the slewing cart and drive device 1 is located on the circular track 3, the reversible moving belt conveyor 4 is located on the slewing cart and drive device 1, and the slewing cart and drive device 1 is connected to a slewing center support device 2. , The slewing center supporting device 2 is fixed on the middle concrete beam at the top hole of the tube tower.

[0060] Such as Figure 5 As shown, the slewing center support device 2 of the present invention includes an upper bearing seat 21, a rotating shaft 22, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com