Positioning module, floor using same and heating device using the floor

A heating device and positioning mold technology, which is applied to floors, floors, building components, etc., can solve the problems of long on-site production and installation period, easy quality problems, and increased project cost of floor heating devices, so as to reduce construction costs and improve construction efficiency. Quick installation and increased space height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

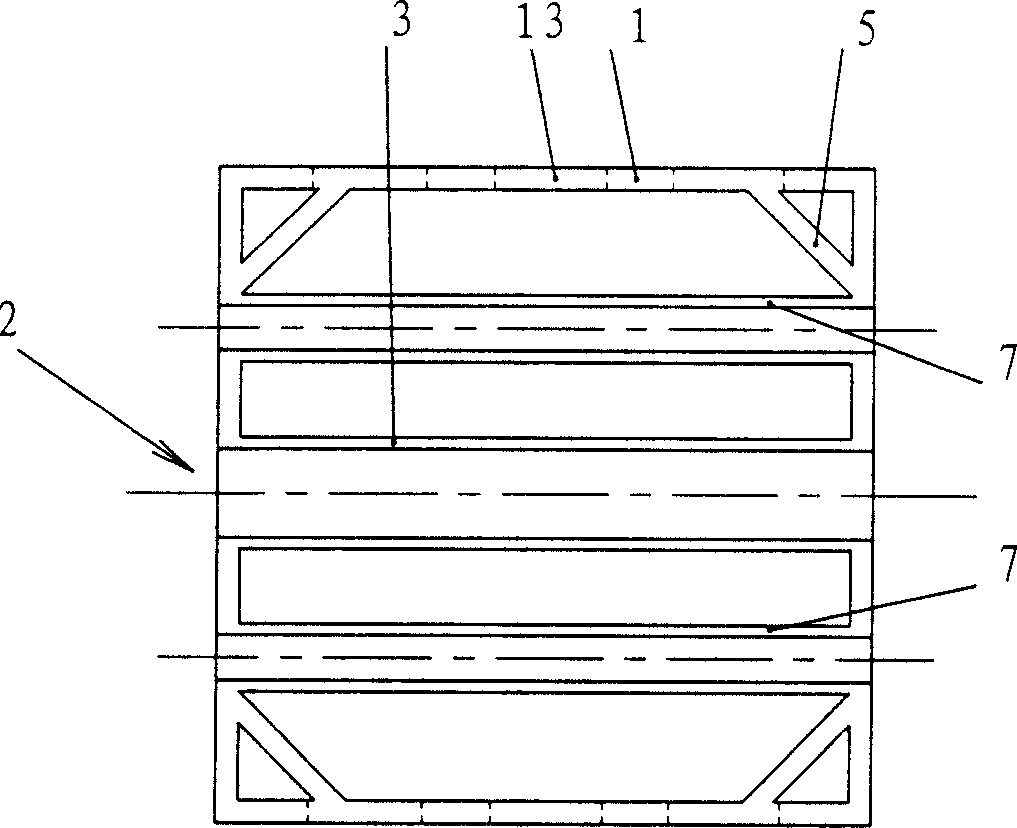

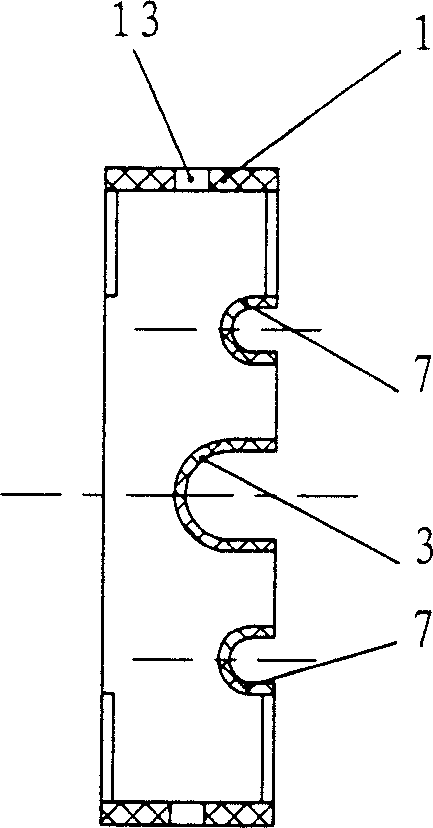

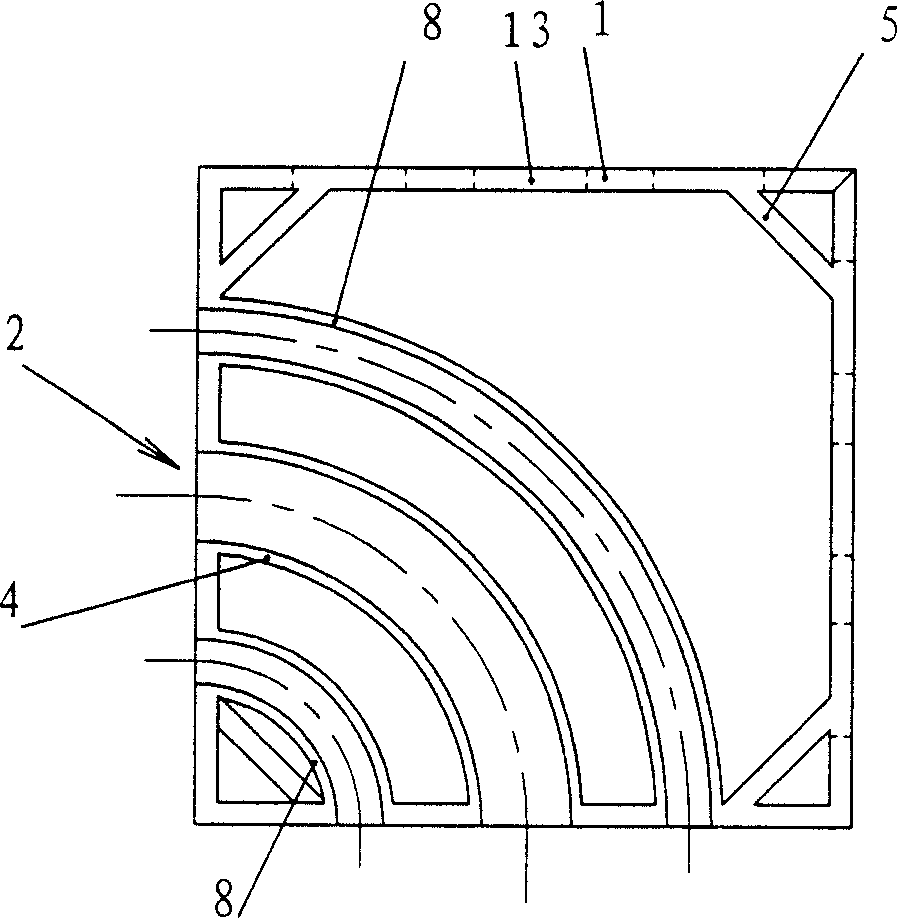

[0021] like figure 1 , figure 2 As shown in Figure 5, the positioning die of the present invention includes a frame 1, and the lower part of the side wall of the frame 1 is provided with a notch 2 with an opening downward, and the notch 2 on the opposite side or the adjacent side in the frame 1 passes through the opening to each other. Connect the grooves below. The floor panel 11 can be made by filling the concrete layer 10 in the frame 1 and above the groove.

[0022] As shown in FIG. 6 , the heating device made of the above-mentioned floor includes a coil 12 connected to the heating device. An insulating layer is provided below the coil 2, and the insulating layers are arranged in horizontal rows and vertical columns respectively. Several floor boards 11 are laid, and coil pipes 12 are arranged in the grooves on the lower surface of each floor board 11 . The coil 12 is made of plastic pipe or copper pipe or aluminum-plastic composite pipe.

[0023] The above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com