Saddle-ride type vehicle with rotary electric machine

A straddle vehicle and rotating motor technology, applied in the field of layout of straddle vehicles, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the present invention will be described below with reference to the drawings.

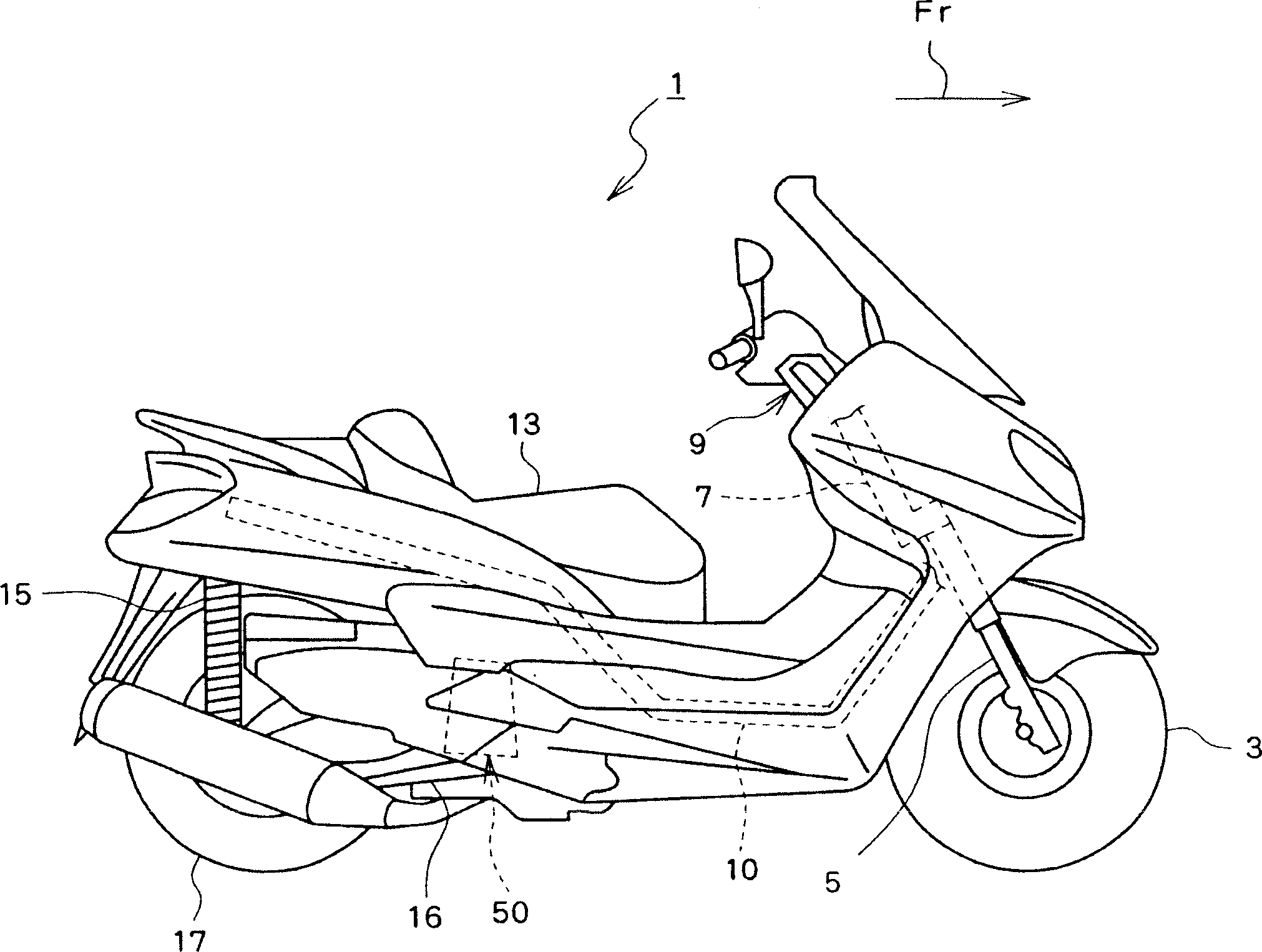

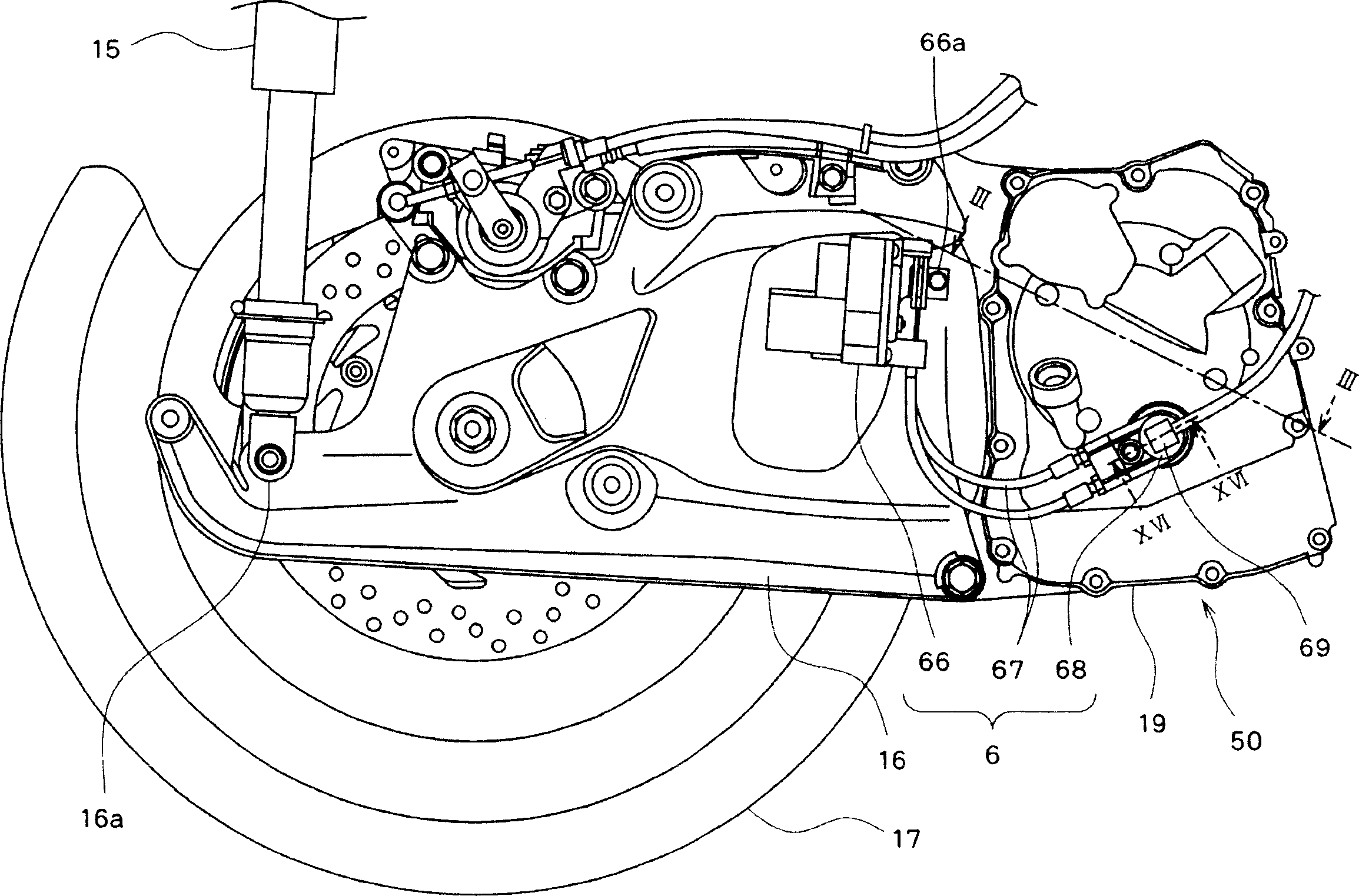

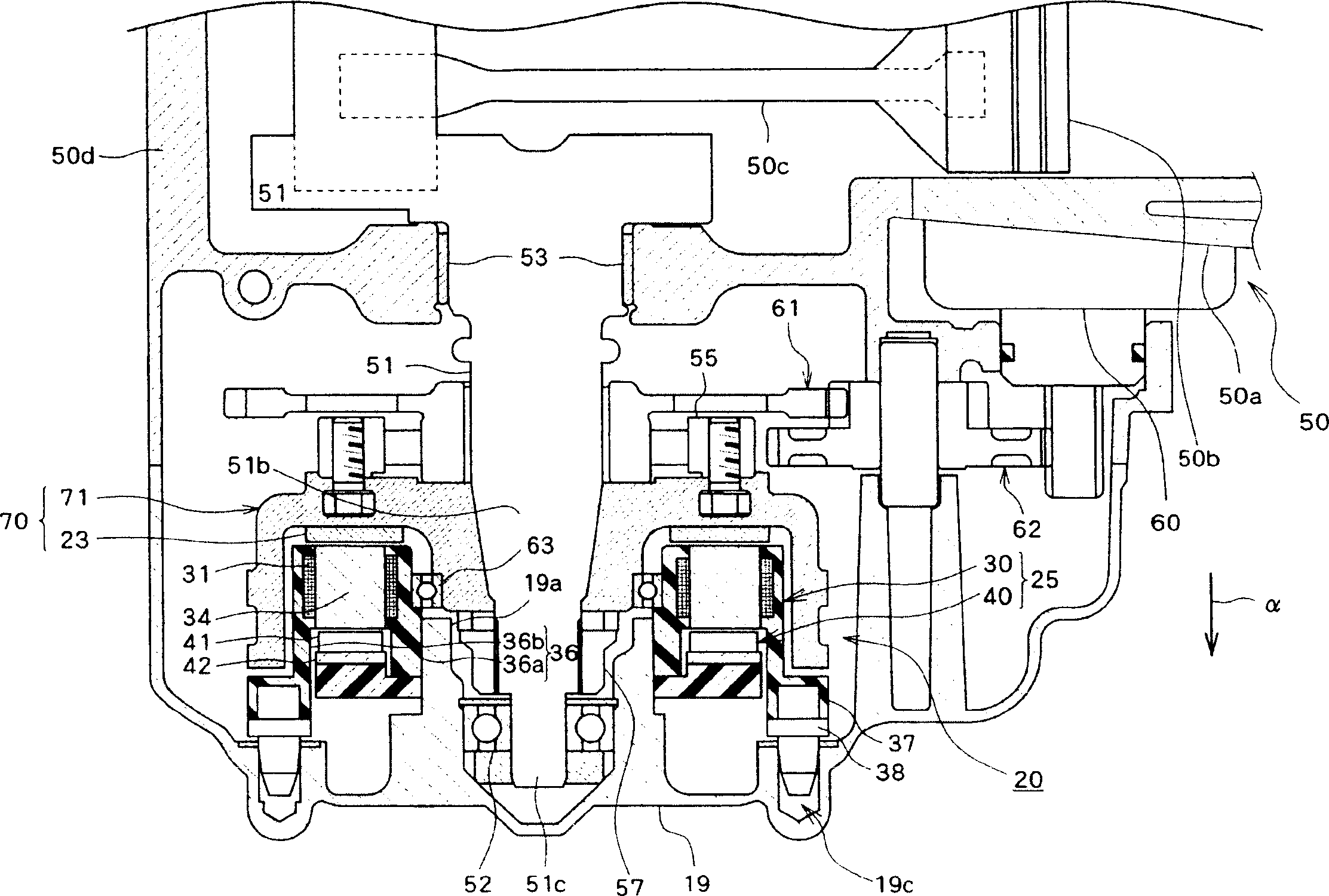

[0060] figure 1 It is a side view of the motorcycle 1 which is an embodiment of the present invention. figure 2 is a side view of the rear of the motorcycle 1, image 3 is along figure 2 The cross-sectional view taken on line III-III, Figure 4 is image 3 An enlarged view of the rotating electrical machine 20 is shown. Figure 5 is an exploded perspective view of the rotary electric machine 20 .

[0061] [Overall structure of the car body]

[0062] Such as figure 1 As shown, the motorcycle 1 has a front wheel 3 at the front lower part of the vehicle body. The front wheel 3 is rotatably supported on the lower end of a front fork 5 . An upwardly extending steering shaft 7 is connected to the upper end of the front fork 5 . A direction bracket 9 extending in the vehicle width direction is attached to the tip end portion of the steering shaft 7 . The body frame 10 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com