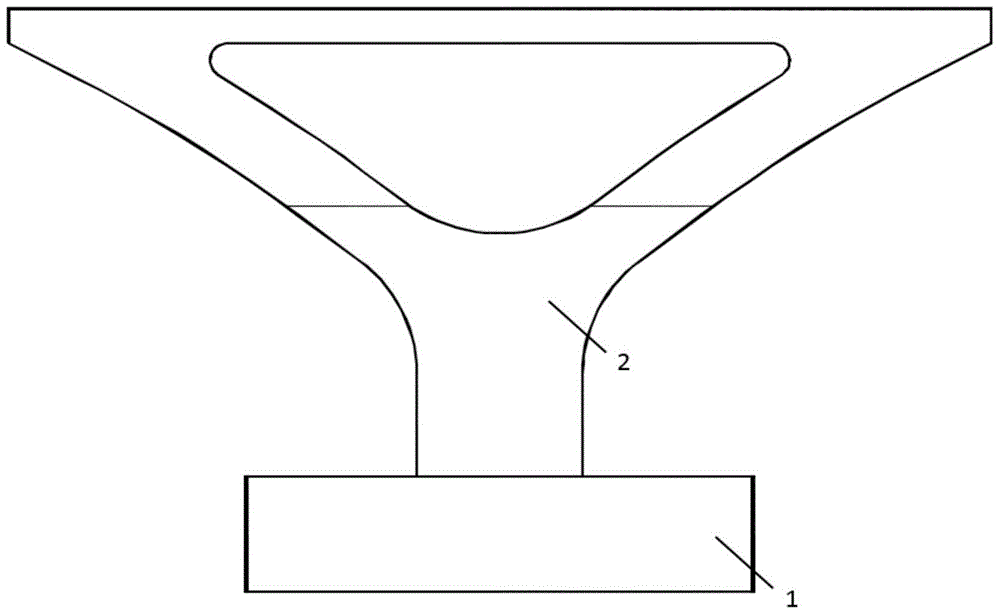

A construction method of composite structure platform for bridge Y-shaped pier construction

A combined structure and platform technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of ineffective application of V-legs, difficult removal of steel pipe piles, complicated support connections, etc., to achieve convenient installation and dismantling, and convenient construction , the effect of less steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

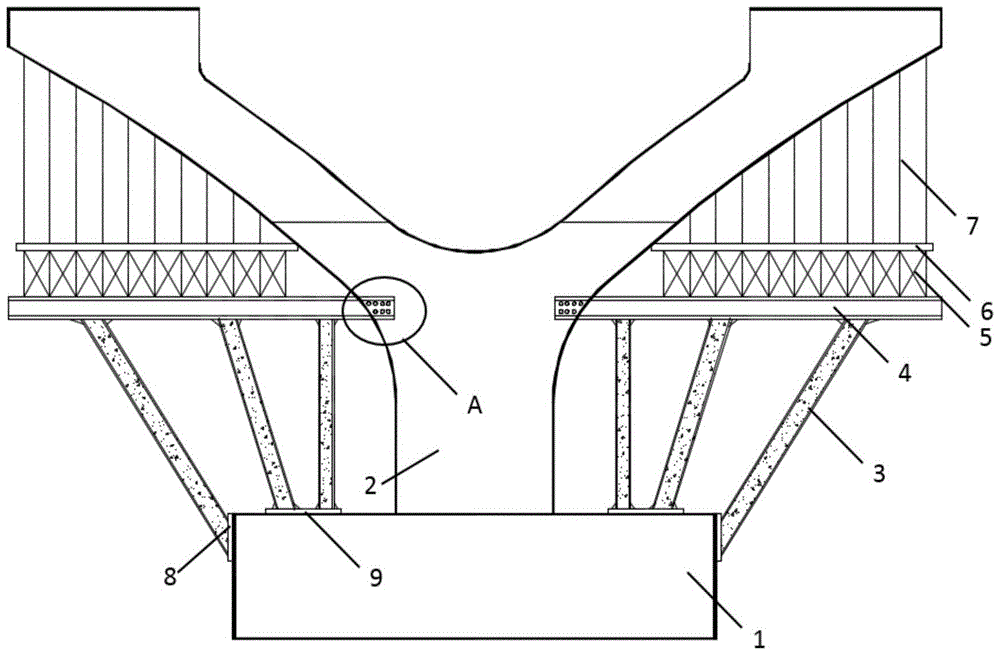

[0040] (1) On the left and right sides of the cap formwork, a plurality of vertical pre-embedded steel plates 8 are arranged at intervals along the longitudinal direction of the cap, and on the top surface of the cap formwork on the left and right sides of the column 2 of the Y-shaped pier to be poured A plurality of horizontal pre-embedded steel plates 9 are respectively arranged at intervals in the longitudinal direction of the platform;

[0041] (2) Pouring the cap 1 in the cap formwork;

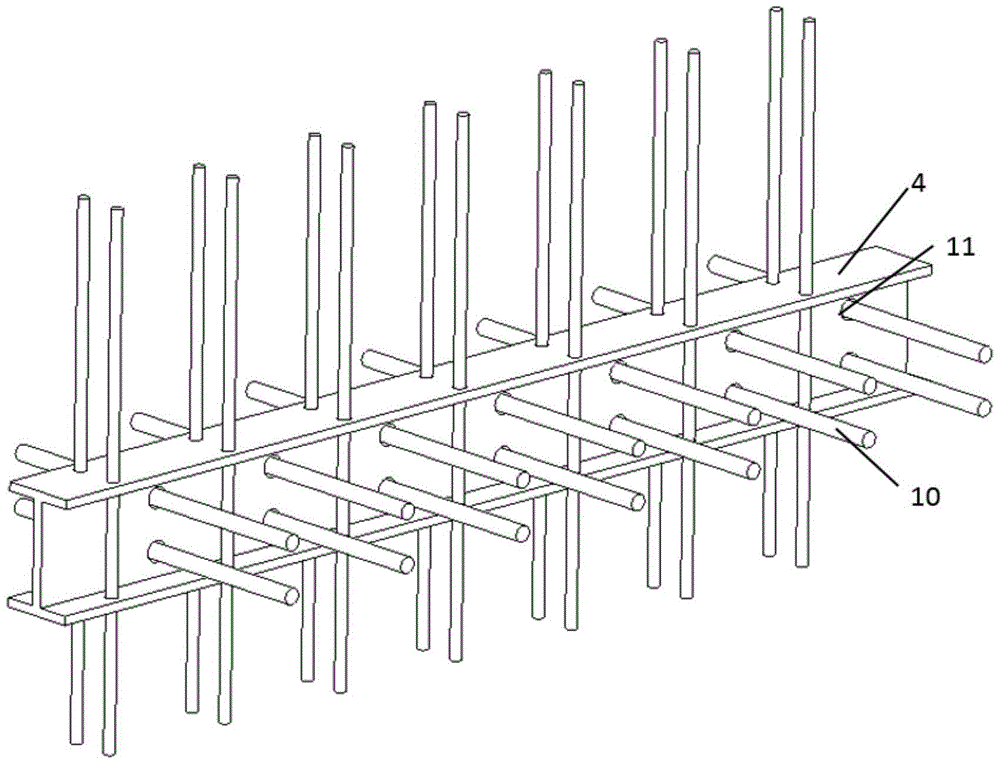

[0042] (3) On both sides of the column 2 of the Y-shaped pier to be poured, a plurality of shaped steel beams 4 of equal height are respectively supported in the horizontal direction and the inner sides of the plurality of shaped steel beams 4 are pierced on the Y-shaped pier to be poured. In the column 2 of the shaped pier, then the reinforcement 10 of the column 2 of the Y-shaped pier to be poured passes through the inner flange of the corresponding shaped steel beam 4 and the preset re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com