Piston machine

A piston and mechanical technology, applied in the field of mechanical construction, can solve the problems of increasing the minimum volume, not providing piston cooling, wasting space, etc., and achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

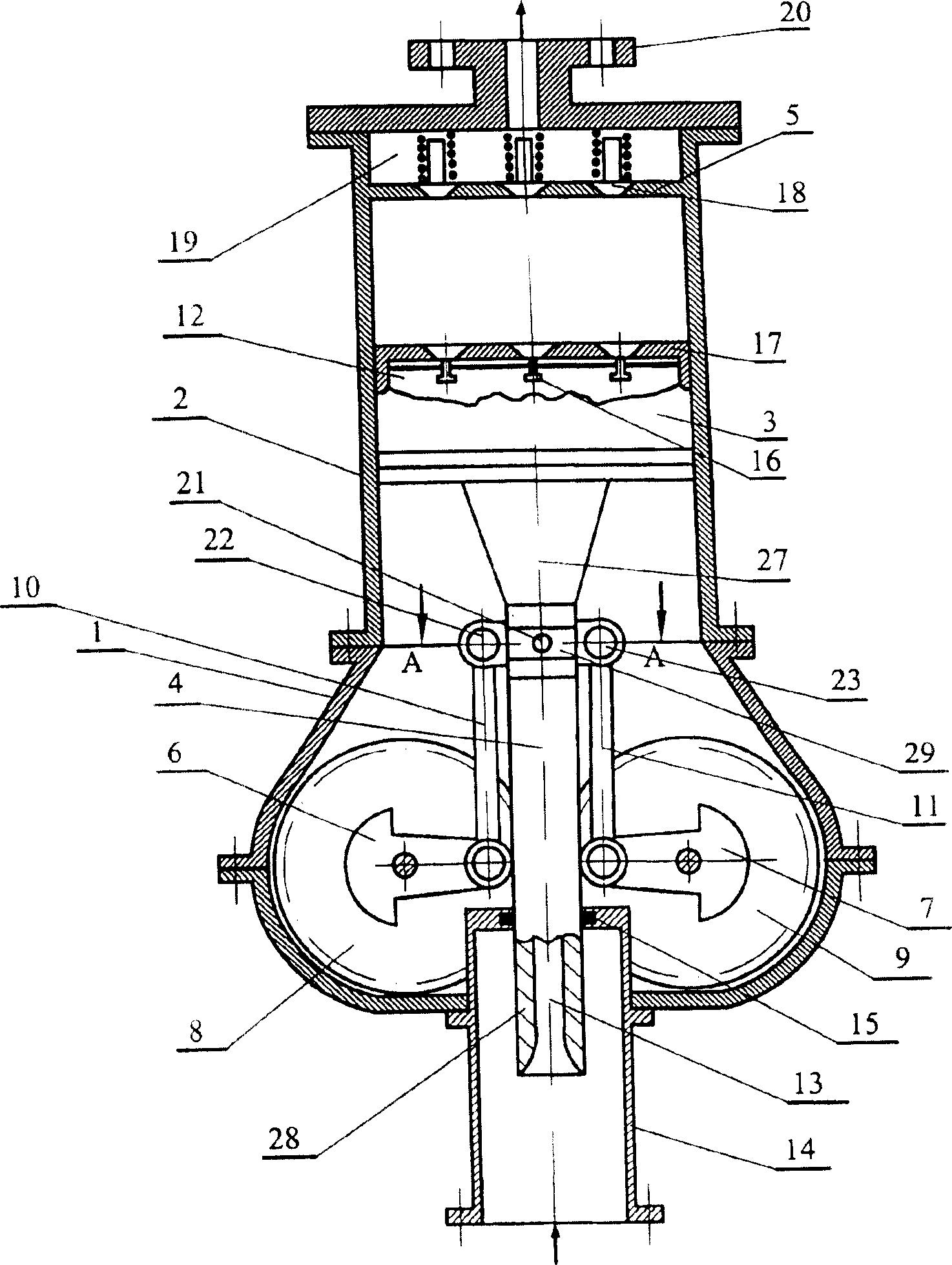

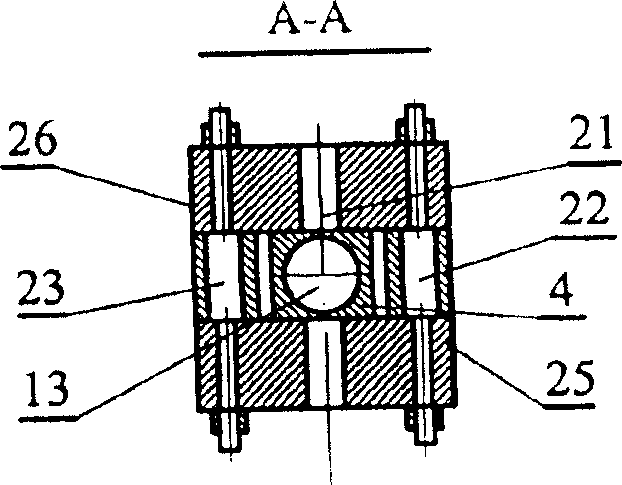

[0015] A piston machine formed as a piston compressor has a crankcase 1 on which a cylinder 2 is fastened, a cover 5 arranged on the cylinder, two parallel crankshafts 6 and 7, wherein a piston 3 with a piston rod 4 is arranged in the cylinder 2 , two parallel crankshafts 6 and 7 with balancing weights arranged symmetrically with respect to the axis of the cylinder 2 and connected to each other, with the possibility of rotation in opposite directions via connected spur gears 8 and 9 .

[0016] Crossbeam 29 is connected with piston rod 4, two connecting rods 10 and 11, each connecting rod 10 and 11 is hingedly connected on one end to corresponding crankshaft 6 or 7, and the other end is hingedly connected to At the respective ends of the beam 29, the above-mentioned two ears 25 and 26 have fingers 22 and 23 fastened to them. The piston rod 4 has a partial square cross-section in the region of the connection with the connecting rod. The piston rod 4 of the piston 3 is hingedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com