Method and apparatus to diagnose mechanical problems in machinery

A numerical method and machine technology, applied in the field of machinery, can solve problems such as distinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

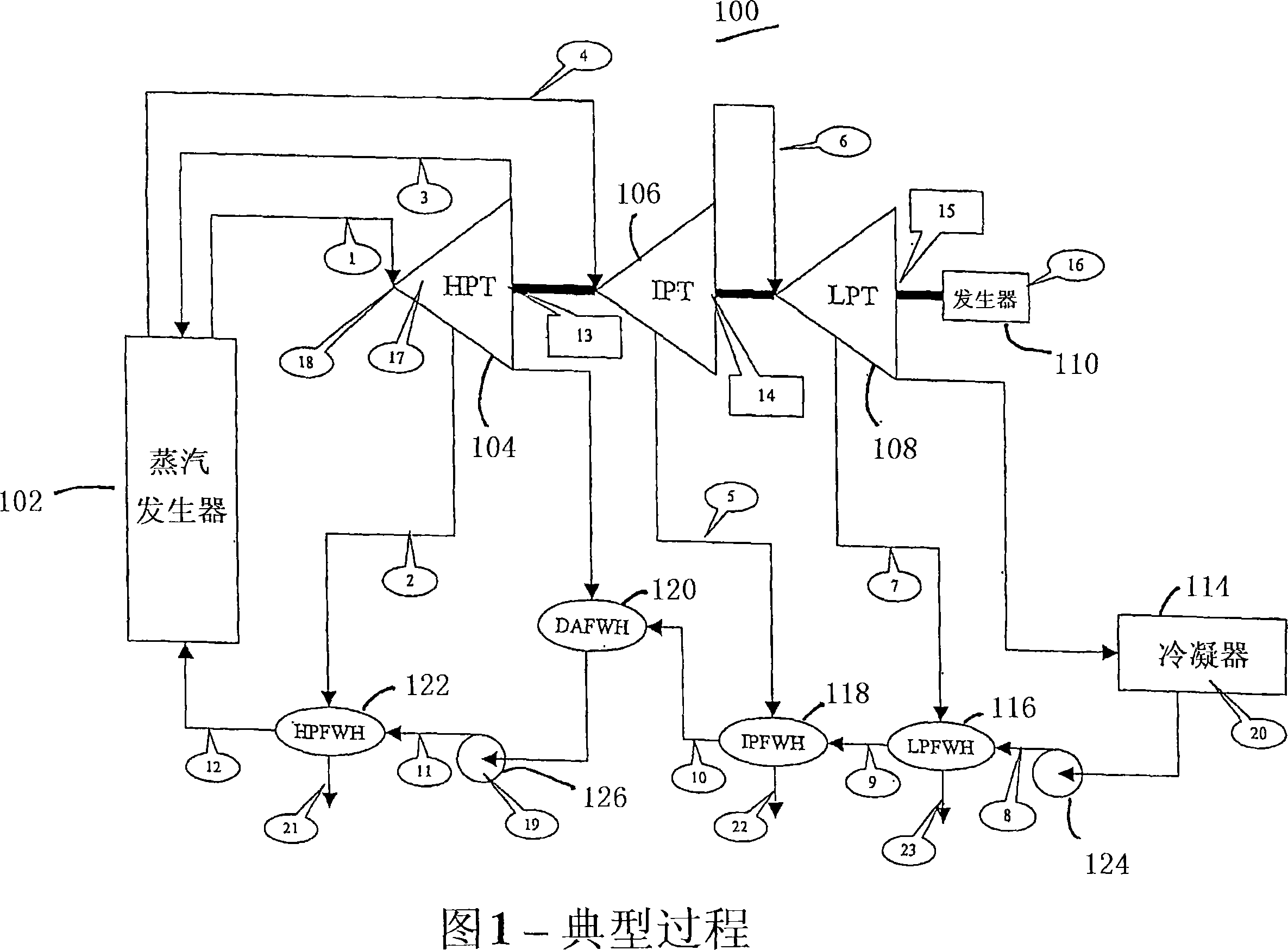

[0042] Referring now to FIG. 1 , there is shown a diagram of process 100 , which is the water / steam side of a boiler / turbine power cycle. As known to those of ordinary skill in the art, the water / steam side process 100 includes a steam generator 102, a high pressure turbine 104, an intermediate pressure turbine 106, a low pressure turbine 108, a generator 110, a condenser 114, a low pressure feedwater heater 118, a degassing De-aerator feedwater heater 120, high-pressure feedwater heater 122, condensate pump 124, and boiler feed pump 126. Although only low-pressure feedwater heater 116, medium-pressure feedwater heater 118, and high-pressure feedwater heater 122 are shown in FIG. A heater is shown for illustration purposes only. It should also be understood that in some installations, heater 118 is located between heater 122 and boiler feed pump 126 .

[0043] sensor

Types of

Measurement

Location

pressure

temperature

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com