Bielectric machine three-clutch series-parallel type mixed power system

A hybrid power system and hybrid technology, which is applied in the system field of the automotive technology field, can solve the problems of complex structure, must be adopted, and low energy feedback efficiency, and achieve the effect of improving economy and strong function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

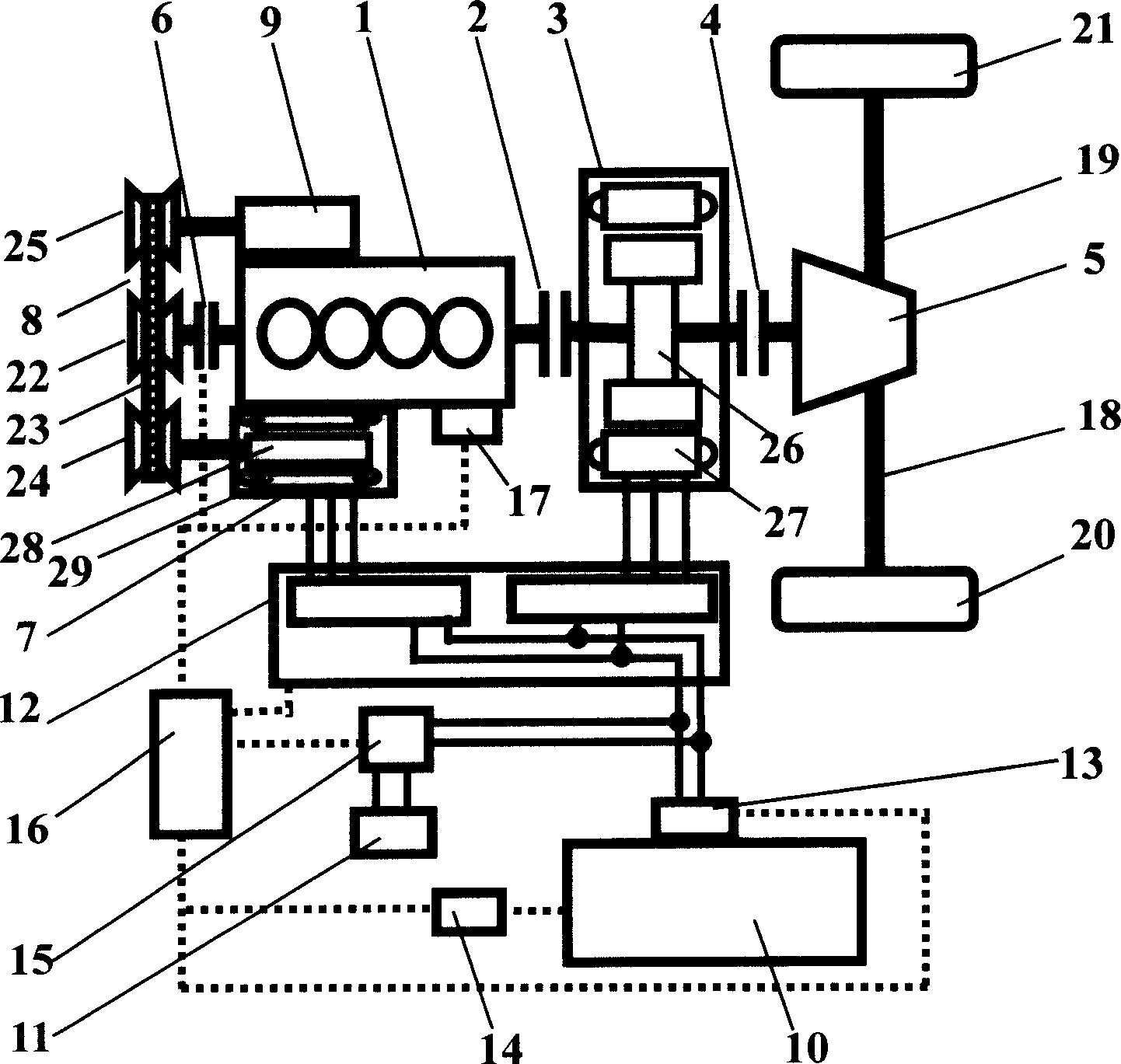

[0012] Such as figure 1 As shown, the present invention includes: engine 1, auxiliary clutch 2, main motor 3, main clutch 4, gearbox 5, pulley clutch 6, pulley motor 7, engine front pulley system 8, engine accessory system 9, power battery 10, auxiliary Battery 11, Motor Drive Controller 12, High Voltage Safety Controller 13, Power Battery Manager 14, DC Converter 15, Vehicle Controller 16, Engine Controller 17, First Half Shaft 18, Second Half Shaft 19 .

[0013] The pulley system 8 at the front end of the engine includes: a driving pulley 22 , a belt 23 , a pulley motor pulley 24 , and a pulley set 25 .

[0014] The main motor 3 includes: a rotor 26 of the main motor 3 and a stator 27 of the main motor 3 .

[0015] The pulley motor 7 includes: a rotor 28 of the pulley motor 7 and a stator 29 of the pulley motor 7 .

[0016] The connecting relation of described each parts is: the front end output shaft of engine 1 links to each other with the driving pulley 22 of engine fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com