Steam compression heat pump using water as working medium

A compression heat pump and steam technology, which is applied in the field of low-temperature waste heat utilization and refrigeration, can solve the problems of decreased performance index, low heat load of a single machine, and limited application scope, and achieves the effect of improving performance index and saving power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

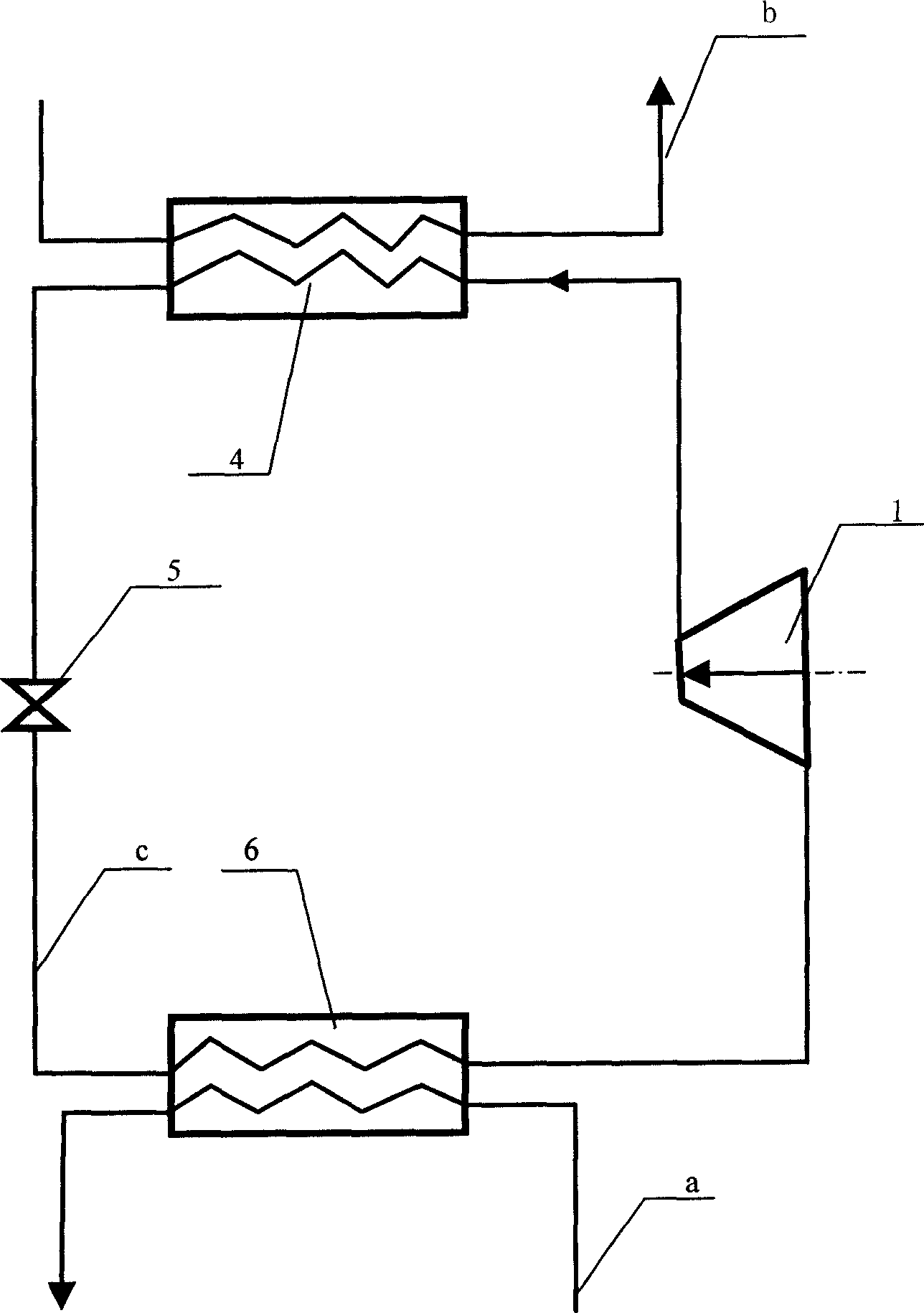

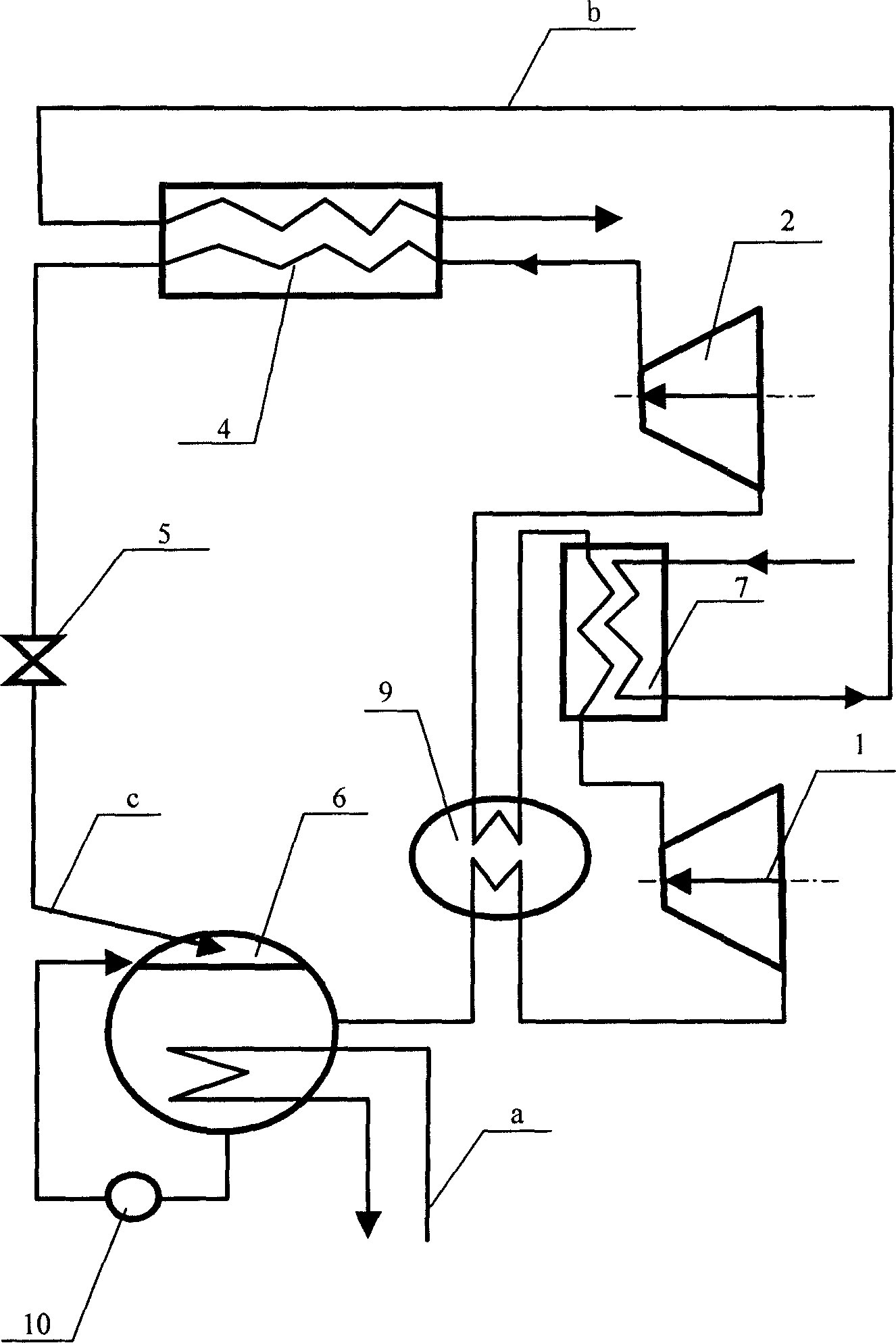

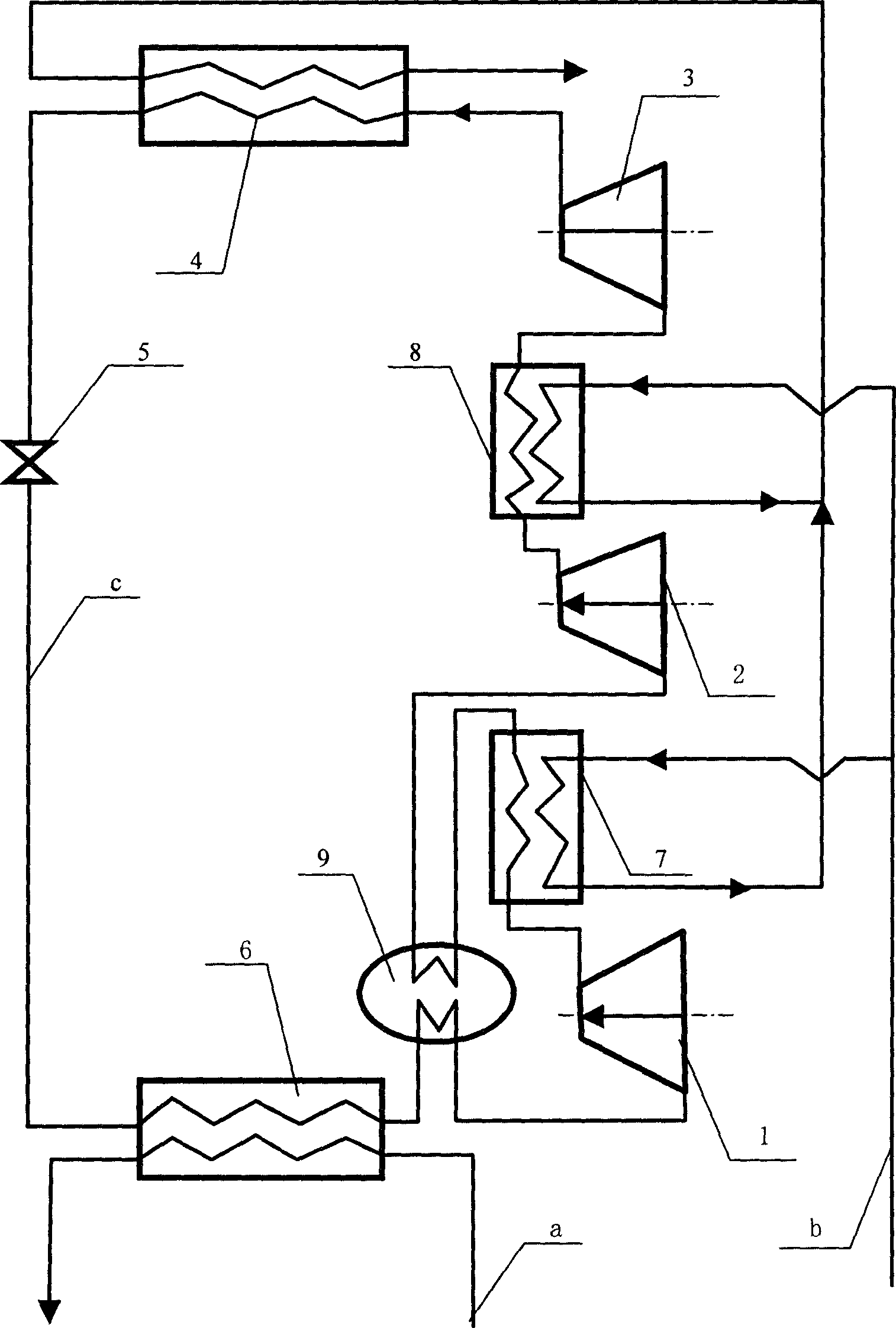

[0028] figure 2 Shown is the structure and process of the vapor compression heat pump provided by the present invention, using water as the working medium, using impeller compressors for two-stage compression and heat extraction between stages, reflecting the essence of the present invention. Structurally, this type of heat pump system is mainly composed of a primary compressor 1, a secondary compressor 2, a condenser 4, a throttle valve 5, an evaporator 6, an interstage heat extractor 7, and a regenerator 9. The waste heat fluid (a) enters and exits the evaporator 6 to complete the heating of the working medium (c) from the condenser 4, which is throttled and depressurized and cooled by the throttle valve 5, to generate low-pressure saturated steam, and its own temperature is reduced; The saturated steam from the evaporator 6 is properly superheate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com