Three-dimensional measurement system and method of the same, and color-coded mark

A three-dimensional measurement and code technology, applied in photogrammetry/video measurement, measurement point marking, measurement device, etc., can solve problems such as low work efficiency, difficulty in full automation, and difficulty in determining different images, and improve efficiency. , to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

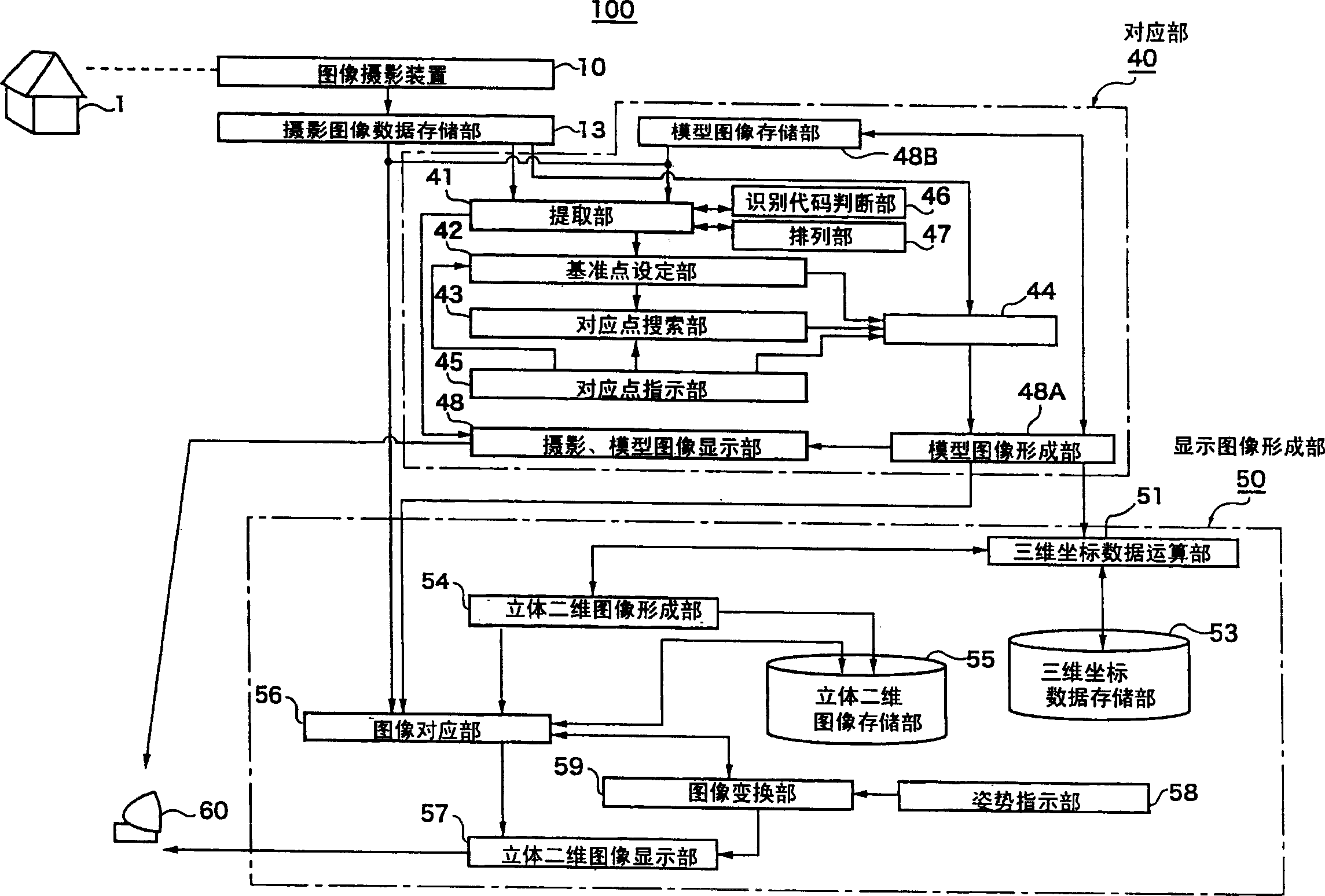

[0066] The invention improves the efficiency of the non-contact three-dimensional measurement and realizes the automation by using the mark (marker) with a code.

[0067] Embodiments of the present invention will be described in detail below with reference to the drawings.

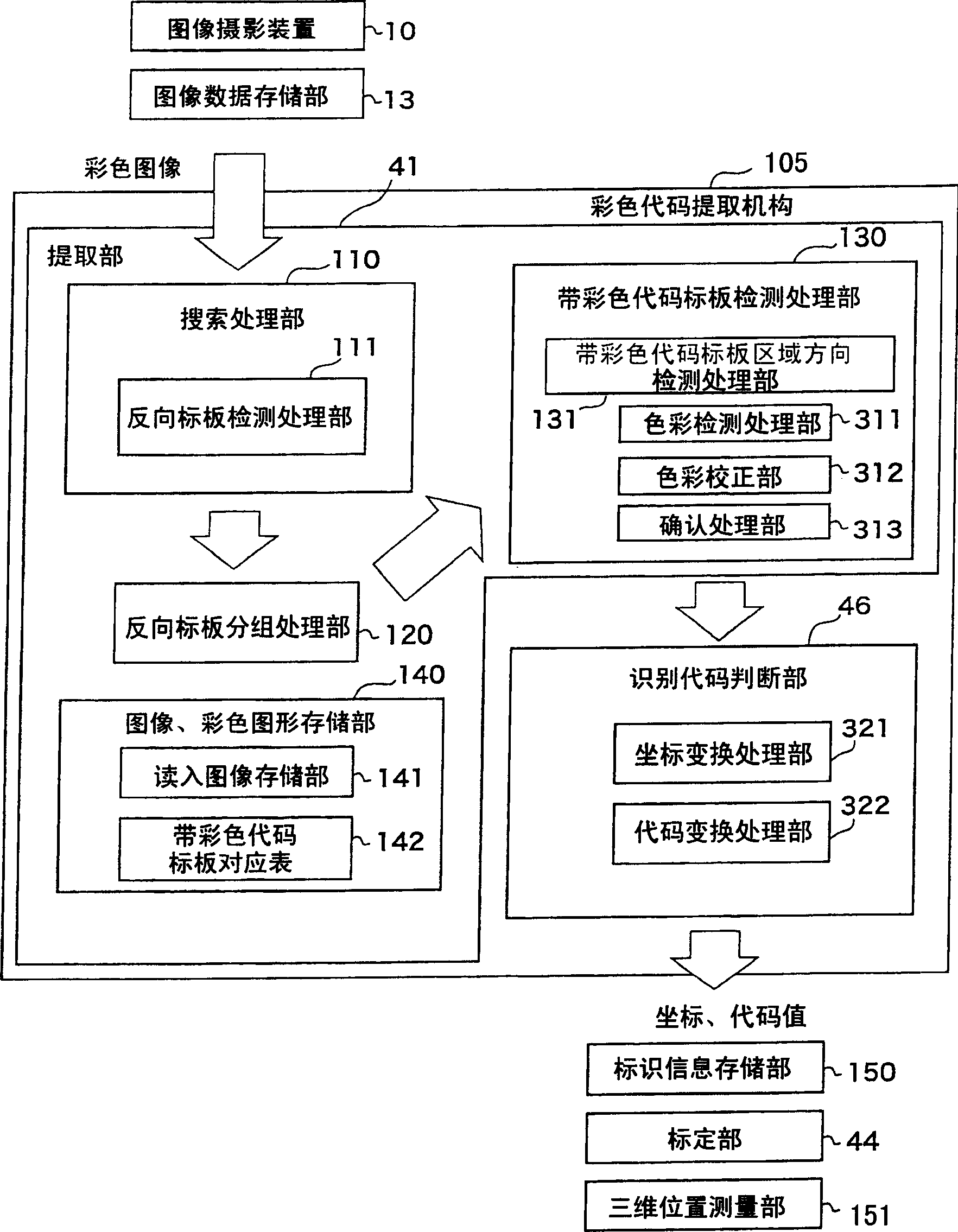

[0068] First, as an example of a coded target, a color coded mark (target) will be described.

[0069] [with color code label]

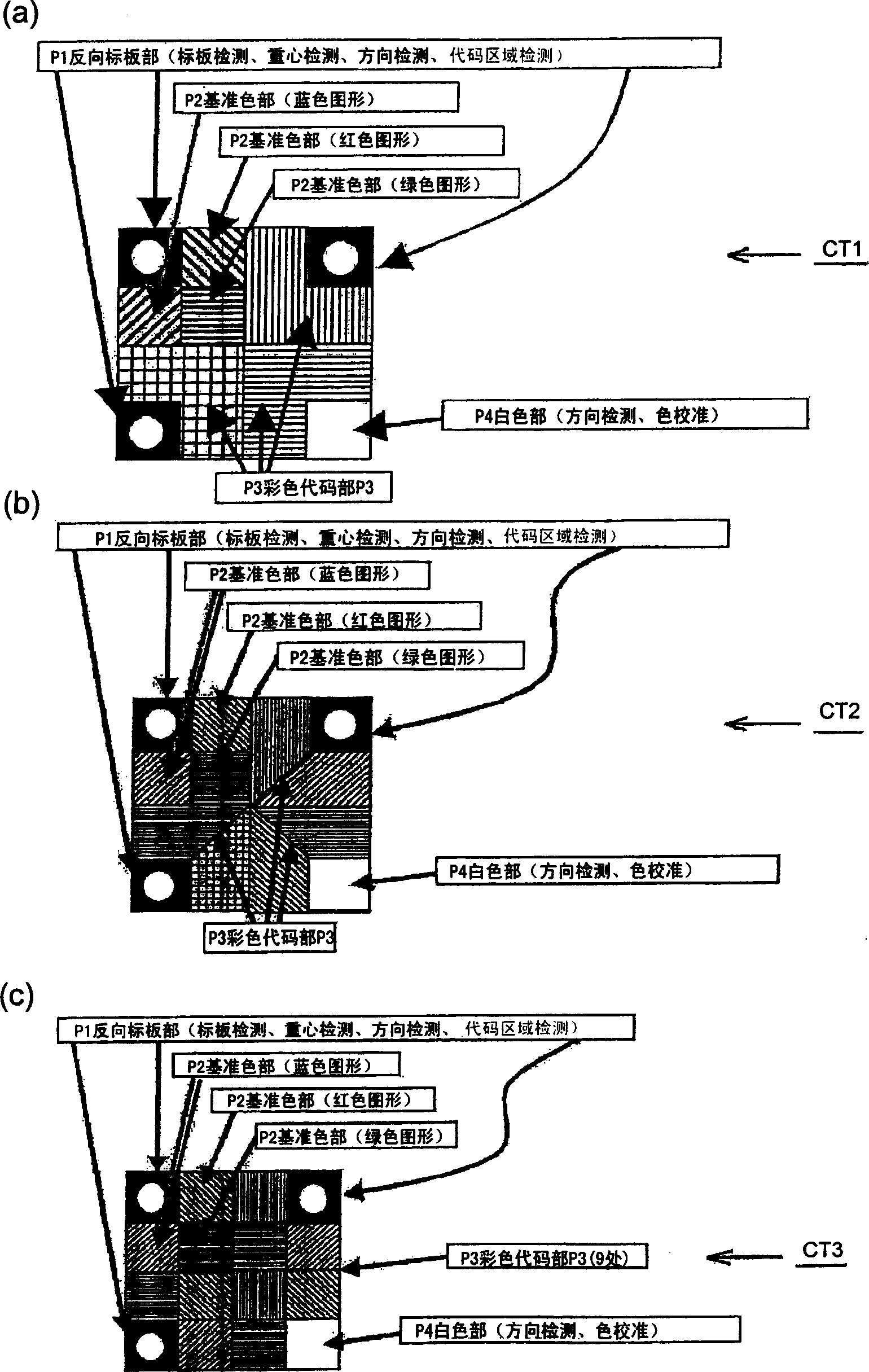

[0070] figure 1 Shown is an example of a color-coded target plate. figure 1 (a) is a color-coded label with three color-coded unit areas, figure 1 (b) is a color-coded label with 6 color-coded unit areas, figure 1 (c) is a color-coded target plate with 9 color-coded unit areas. figure 1 (a)~(c) with color coded target CT (CT1~CT3), consists of position detection pattern (reverse target part) P1, reference color pattern (reference color part) P2, color code pattern (color Code part) P3, empty figure (white part) P4 constitutes.

[0071] The reverse target unit P1 is us...

no. 2 Embodiment approach

[0266] Instead of pasting the color-coded target CT, or in combination with the pasting of the color-coded target CT, the reference pattern may be projected onto the measurement object 1 by the projection device 12 .

[0267] Figure 23 It is a block diagram of an example of the overall configuration of a three-dimensional measurement system 100A in the second embodiment. with the first embodiment (see figure 2 ) compared with the three-dimensional measurement system 100 in ), the projection device 12 and the calculation processing unit 49 are added, and the other structures are the same as those of the first embodiment. The projection device 12 projects various patterns such as a pattern for position detection onto the object 1 to be measured, and the various projected patterns are photographed by the imaging device 10 for calibration and three-dimensional measurement. The calculation processing unit 49 receives image data, detects various patterns, generates various patte...

no. 3 Embodiment approach

[0282] In this embodiment, an example in which a color reverse target is used as the pattern P1 for position detection will be described.

[0283] In this embodiment, the method of using the colored position detection pattern in (4) is adopted as a search method for target position extraction.

[0284] (4) Different colors are used for the three-cornered reverse targets of the color coded target CT, so that the reflected colors of each reverse target are different. The reverse targets of the 3 corners are made to have different colors, so it is easy to judge each reverse target belonging to one color-coded target. In the reverse target grouping process, when multiple reverse targets are used, reverse targets of different colors are also used to select the closest one, which makes the process easier.

[0285] In the case of using multiple reverse targets as the reference point RF, the reverse target with color-coded CT and a single reverse target are mixed, so the reverse targ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com